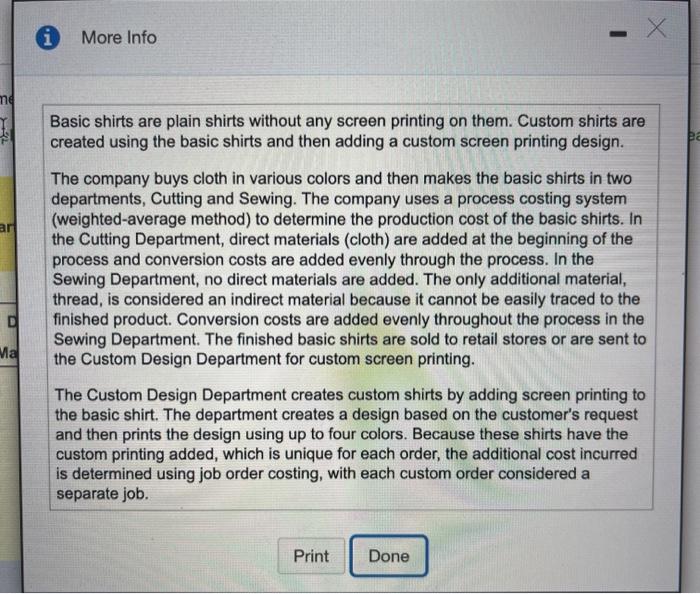

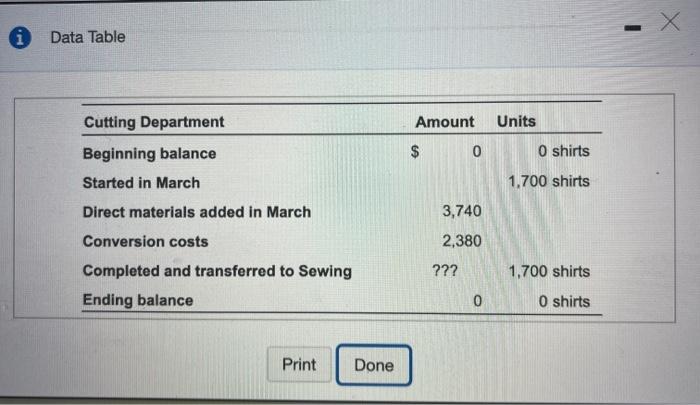

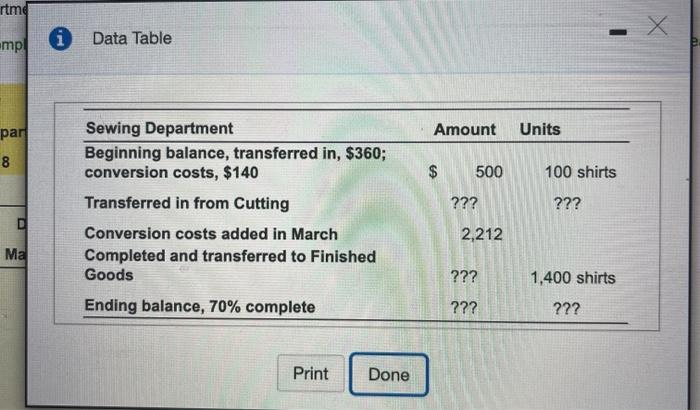

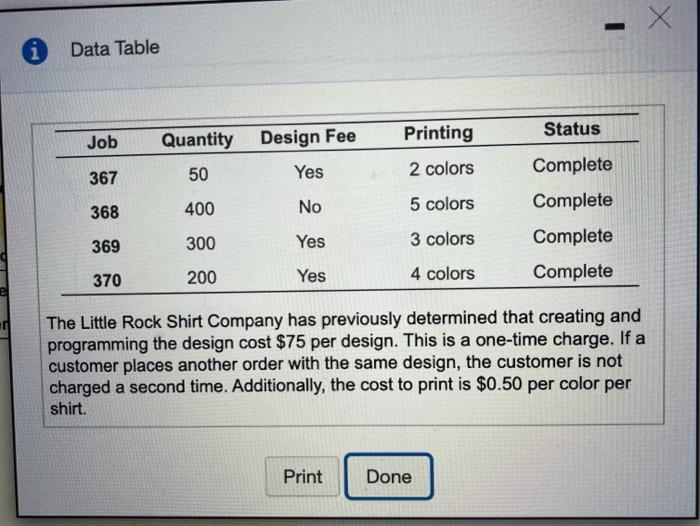

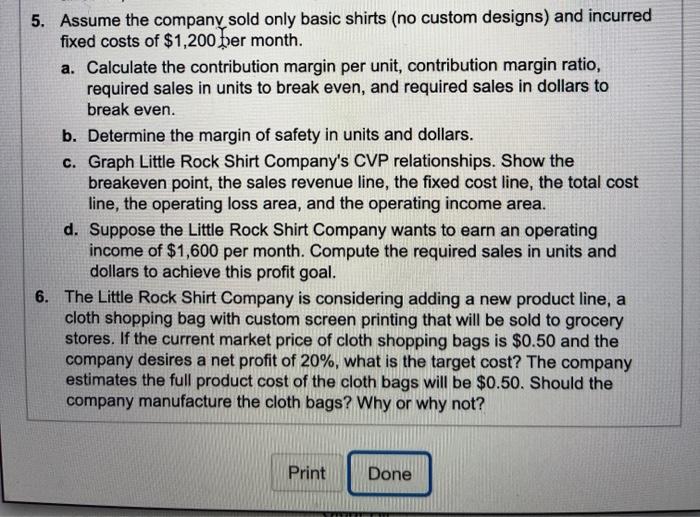

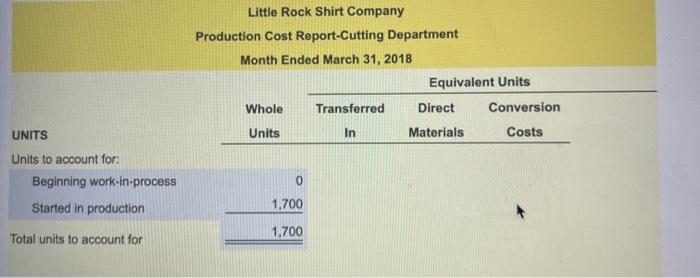

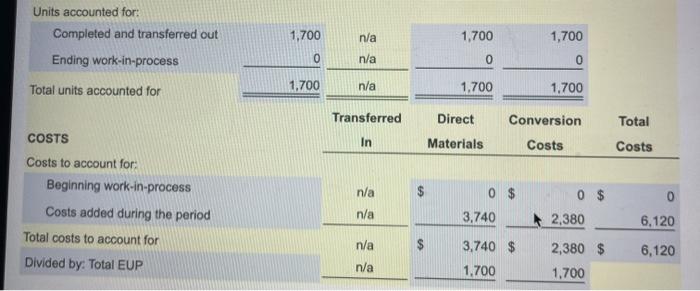

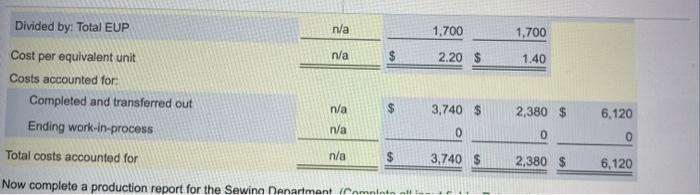

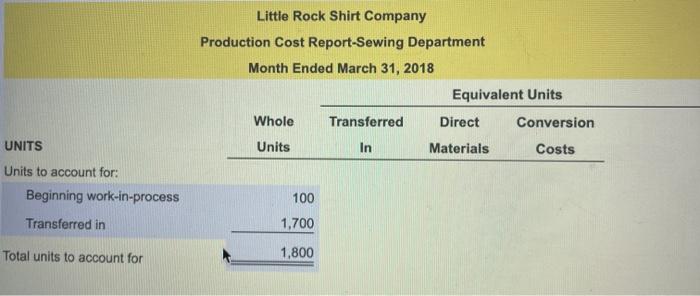

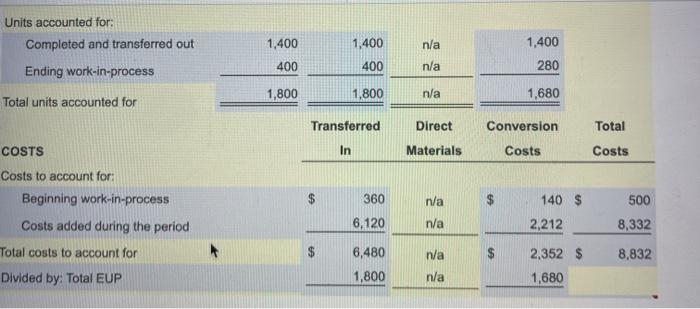

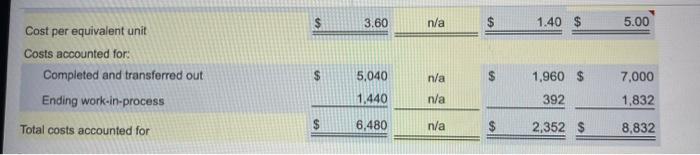

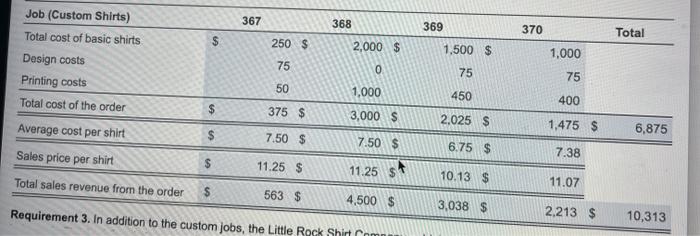

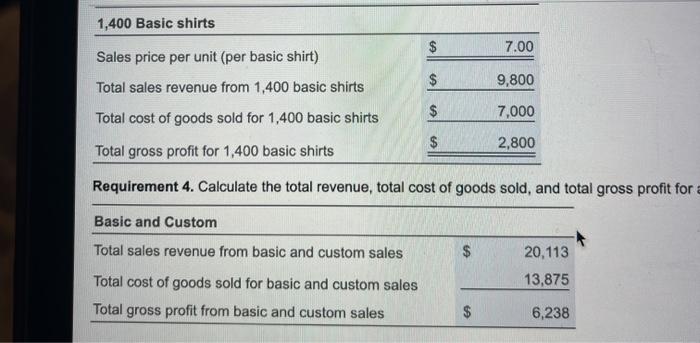

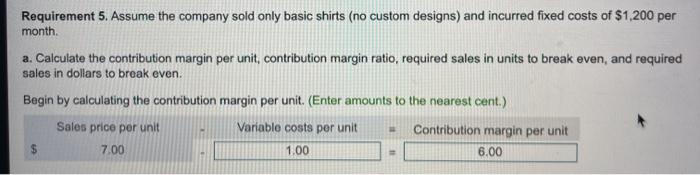

* More Info mo ar Basic shirts are plain shirts without any screen printing on them. Custom shirts are created using the basic shirts and then adding a custom screen printing design. The company buys cloth in various colors and then makes the basic shirts in two departments, Cutting and Sewing. The company uses a process costing system (weighted average method) to determine the production cost of the basic shirts. In the Cutting Department, direct materials (cloth) are added at the beginning of the process and conversion costs are added evenly through the process. In the Sewing Department, no direct materials are added. The only additional material, thread, is considered an indirect material because it cannot be easily traced to the finished product. Conversion costs are added evenly throughout the process in the Sewing Department. The finished basic shirts are sold to retail stores or are sent to the Custom Design Department for custom screen printing. The Custom Design Department creates custom shirts by adding screen printing to the basic shirt. The department creates a design based on the customer's request and then prints the design using up to four colors. Because these shirts have the custom printing added, which is unique for each order, the additional cost incurred is determined using job order costing, with each custom order considered a separate job. Print Done i Data Table Cutting Department Amount Units $ 0 O shirts Beginning balance Started in March 1,700 shirts Direct materials added in March 3,740 Conversion costs 2,380 ??? 1,700 shirts Completed and transferred to Sewing Ending balance 0 O shirts Print Done rtme mpl i Data Table par Amount Units 8 $ 500 100 shirts Sewing Department Beginning balance, transferred in, $360; conversion costs, $140 Transferred in from Cutting Conversion costs added in March Completed and transferred to Finished Goods ??? ??? 2,212 Ma ??? 1,400 shirts Ending balance, 70% complete ??? ??? Print Done X - i Data Table Status Job Quantity Design Fee 367 50 Yes Printing 2 colors 5 colors 3 colors Complete Complete 368 400 No 369 300 Yes Complete 370 200 Yes 4 colors Complete The Little Rock Shirt Company has previously determined that creating and programming the design cost $75 per design. This is a one-time charge. If a customer places another order with the same design, the customer is not charged a second time. Additionally, the cost to print is $0.50 per color per shirt. Print Done 5. Assume the company sold only basic shirts (no custom designs) and incurred fixed costs of $1,200 per month. a. Calculate the contribution margin per unit, contribution margin ratio, required sales in units to break even, and required sales in dollars to break even. b. Determine the margin of safety in units and dollars. C. Graph Little Rock Shirt Company's CVP relationships. Show the breakeven point, the sales revenue line, the fixed cost line, the total cost line, the operating loss area, and the operating income area. d. Suppose the Little Rock Shirt Company wants to earn an operating income of $1,600 per month. Compute the required sales in units and dollars to achieve this profit goal. 6. The Little Rock Shirt Company is considering adding a new product line, a cloth shopping bag with custom screen printing that will be sold to grocery stores. If the current market price of cloth shopping bags is $0.50 and the company desires a net profit of 20%, what is the target cost? The company estimates the full product cost of the cloth bags will be $0.50. Should the company manufacture the cloth bags? Why or why not? Print Done Little Rock Shirt Company Production Cost Report-Cutting Department Month Ended March 31, 2018 Equivalent Units Whole Transferred Direct Conversion Units In Materials Costs UNITS Units to account for: Beginning work-in-process Started in production 1,700 1,700 Total units to account for 1,700 n/a 1,700 1,700 Units accounted for: Completed and transferred out Ending work-in-process Total units accounted for 0 n/a 0 0 1.700 n/a 1,700 1.700 Transferred Direct Conversion Total COSTS In Materials Costs Costs Costs to account for: Beginning work-in-process Costs added during the period n/a $ 0 $ n/a 3,740 2,380 6,120 Total costs to account for n/a $ 6,120 Divided by: Total EUP 3,740 $ 1.700 n/a 2,380 $ 1.700 n/a 1,700 1,700 n/a $ 2.20 $ 1.40 Divided by: Total EUP Cost per equivalent unit Costs accounted for: Completed and transferred out Ending work-in-process n/a $ 3,740 $ 2,380 $ 6,120 n/a 0 0 0 Total costs accounted for n/a $ $ 3,740 $ 2,380 $ 6,120 Now complete a production report for the Sewino Denartment (Camnan Little Rock Shirt Company Production Cost Report-Sewing Department Month Ended March 31, 2018 Equivalent Units Whole Transferred Direct Conversion Costs Units In Materials UNITS Units to account for: Beginning work-in-process Transferred in 100 1,700 Total units to account for 1,800 Units accounted for: Completed and transferred out Ending work-in-process 1,400 1,400 n/a 1,400 400 400 n/a 280 1,800 1,800 n/a 1,680 Total units accounted for Transferred Direct Conversion Total In Materials Costs Costs 360 n/a $ 140 $ 500 COSTS Costs to account for: Beginning work-in-process Costs added during the period Total costs to account for Divided by: Total EUP 6,120 n/a 2,212 8,332 n/a $ 8,832 6,480 1,800 2,352 $ 1,680 n/a $ 3.60 n/a $ 1.40 $ 5.00 Cost per equivalent unit Costs accounted for: Completed and transferred out Ending work-in-process S 5,040 n/a 1,960 392 7,000 1,832 1.440 n/a Total costs accounted for $ 6,480 n/a $ 2,352 $ 8,832 367 368 369 370 Total $ 250 $ 2,000 $ 1.500 $ Job (Custom Shirts) Total cost of basic shirts Design costs Printing costs Total cost of the order 1,000 75 0 75 75 50 1,000 450 400 375 $ $ $ 3,000 $ 2.025 $ Average cost per shirt 1,475 $ 6,875 7.50 $ 7.50 $ 6.75 $ Sales price per shirt 7.38 $ 11.25 $ 11.25 10.13 $ Total sales revenue from the order 11.07 $ 563 $ 4,500 $ 3,038 $ Requirement 3. In addition to the custom jobs, the Little Rock Shirt Com 2.213 $ 10,313 1,400 Basic shirts 7.00 Sales price per unit (per basic shirt) $ $ 9,800 Total sales revenue from 1,400 basic shirts $ 7,000 Total cost of goods sold for 1,400 basic shirts $ 2,800 Total gross profit for 1,400 basic shirts Requirement 4. Calculate the total revenue, total cost of goods sold, and total gross profit for = Basic and Custom Total sales revenue from basic and custom sales $ 20,113 13,875 Total cost of goods sold for basic and custom sales Total gross profit from basic and custom sales $ 6,238 Requirement 5. Assume the company sold only basic shirts (no custom designs) and incurred fixed costs of $1,200 per month a. Calculate the contribution margin per unit, contribution margin ratio, required sales in units to break even, and required sales in dollars to break even. Begin by calculating the contribution margin per unit. (Enter amounts to the nearest cent.) Sales price per unit Variable costs per unit Contribution margin per unit 7.00 6.00 1.00 * More Info mo ar Basic shirts are plain shirts without any screen printing on them. Custom shirts are created using the basic shirts and then adding a custom screen printing design. The company buys cloth in various colors and then makes the basic shirts in two departments, Cutting and Sewing. The company uses a process costing system (weighted average method) to determine the production cost of the basic shirts. In the Cutting Department, direct materials (cloth) are added at the beginning of the process and conversion costs are added evenly through the process. In the Sewing Department, no direct materials are added. The only additional material, thread, is considered an indirect material because it cannot be easily traced to the finished product. Conversion costs are added evenly throughout the process in the Sewing Department. The finished basic shirts are sold to retail stores or are sent to the Custom Design Department for custom screen printing. The Custom Design Department creates custom shirts by adding screen printing to the basic shirt. The department creates a design based on the customer's request and then prints the design using up to four colors. Because these shirts have the custom printing added, which is unique for each order, the additional cost incurred is determined using job order costing, with each custom order considered a separate job. Print Done i Data Table Cutting Department Amount Units $ 0 O shirts Beginning balance Started in March 1,700 shirts Direct materials added in March 3,740 Conversion costs 2,380 ??? 1,700 shirts Completed and transferred to Sewing Ending balance 0 O shirts Print Done rtme mpl i Data Table par Amount Units 8 $ 500 100 shirts Sewing Department Beginning balance, transferred in, $360; conversion costs, $140 Transferred in from Cutting Conversion costs added in March Completed and transferred to Finished Goods ??? ??? 2,212 Ma ??? 1,400 shirts Ending balance, 70% complete ??? ??? Print Done X - i Data Table Status Job Quantity Design Fee 367 50 Yes Printing 2 colors 5 colors 3 colors Complete Complete 368 400 No 369 300 Yes Complete 370 200 Yes 4 colors Complete The Little Rock Shirt Company has previously determined that creating and programming the design cost $75 per design. This is a one-time charge. If a customer places another order with the same design, the customer is not charged a second time. Additionally, the cost to print is $0.50 per color per shirt. Print Done 5. Assume the company sold only basic shirts (no custom designs) and incurred fixed costs of $1,200 per month. a. Calculate the contribution margin per unit, contribution margin ratio, required sales in units to break even, and required sales in dollars to break even. b. Determine the margin of safety in units and dollars. C. Graph Little Rock Shirt Company's CVP relationships. Show the breakeven point, the sales revenue line, the fixed cost line, the total cost line, the operating loss area, and the operating income area. d. Suppose the Little Rock Shirt Company wants to earn an operating income of $1,600 per month. Compute the required sales in units and dollars to achieve this profit goal. 6. The Little Rock Shirt Company is considering adding a new product line, a cloth shopping bag with custom screen printing that will be sold to grocery stores. If the current market price of cloth shopping bags is $0.50 and the company desires a net profit of 20%, what is the target cost? The company estimates the full product cost of the cloth bags will be $0.50. Should the company manufacture the cloth bags? Why or why not? Print Done Little Rock Shirt Company Production Cost Report-Cutting Department Month Ended March 31, 2018 Equivalent Units Whole Transferred Direct Conversion Units In Materials Costs UNITS Units to account for: Beginning work-in-process Started in production 1,700 1,700 Total units to account for 1,700 n/a 1,700 1,700 Units accounted for: Completed and transferred out Ending work-in-process Total units accounted for 0 n/a 0 0 1.700 n/a 1,700 1.700 Transferred Direct Conversion Total COSTS In Materials Costs Costs Costs to account for: Beginning work-in-process Costs added during the period n/a $ 0 $ n/a 3,740 2,380 6,120 Total costs to account for n/a $ 6,120 Divided by: Total EUP 3,740 $ 1.700 n/a 2,380 $ 1.700 n/a 1,700 1,700 n/a $ 2.20 $ 1.40 Divided by: Total EUP Cost per equivalent unit Costs accounted for: Completed and transferred out Ending work-in-process n/a $ 3,740 $ 2,380 $ 6,120 n/a 0 0 0 Total costs accounted for n/a $ $ 3,740 $ 2,380 $ 6,120 Now complete a production report for the Sewino Denartment (Camnan Little Rock Shirt Company Production Cost Report-Sewing Department Month Ended March 31, 2018 Equivalent Units Whole Transferred Direct Conversion Costs Units In Materials UNITS Units to account for: Beginning work-in-process Transferred in 100 1,700 Total units to account for 1,800 Units accounted for: Completed and transferred out Ending work-in-process 1,400 1,400 n/a 1,400 400 400 n/a 280 1,800 1,800 n/a 1,680 Total units accounted for Transferred Direct Conversion Total In Materials Costs Costs 360 n/a $ 140 $ 500 COSTS Costs to account for: Beginning work-in-process Costs added during the period Total costs to account for Divided by: Total EUP 6,120 n/a 2,212 8,332 n/a $ 8,832 6,480 1,800 2,352 $ 1,680 n/a $ 3.60 n/a $ 1.40 $ 5.00 Cost per equivalent unit Costs accounted for: Completed and transferred out Ending work-in-process S 5,040 n/a 1,960 392 7,000 1,832 1.440 n/a Total costs accounted for $ 6,480 n/a $ 2,352 $ 8,832 367 368 369 370 Total $ 250 $ 2,000 $ 1.500 $ Job (Custom Shirts) Total cost of basic shirts Design costs Printing costs Total cost of the order 1,000 75 0 75 75 50 1,000 450 400 375 $ $ $ 3,000 $ 2.025 $ Average cost per shirt 1,475 $ 6,875 7.50 $ 7.50 $ 6.75 $ Sales price per shirt 7.38 $ 11.25 $ 11.25 10.13 $ Total sales revenue from the order 11.07 $ 563 $ 4,500 $ 3,038 $ Requirement 3. In addition to the custom jobs, the Little Rock Shirt Com 2.213 $ 10,313 1,400 Basic shirts 7.00 Sales price per unit (per basic shirt) $ $ 9,800 Total sales revenue from 1,400 basic shirts $ 7,000 Total cost of goods sold for 1,400 basic shirts $ 2,800 Total gross profit for 1,400 basic shirts Requirement 4. Calculate the total revenue, total cost of goods sold, and total gross profit for = Basic and Custom Total sales revenue from basic and custom sales $ 20,113 13,875 Total cost of goods sold for basic and custom sales Total gross profit from basic and custom sales $ 6,238 Requirement 5. Assume the company sold only basic shirts (no custom designs) and incurred fixed costs of $1,200 per month a. Calculate the contribution margin per unit, contribution margin ratio, required sales in units to break even, and required sales in dollars to break even. Begin by calculating the contribution margin per unit. (Enter amounts to the nearest cent.) Sales price per unit Variable costs per unit Contribution margin per unit 7.00 6.00 1.00