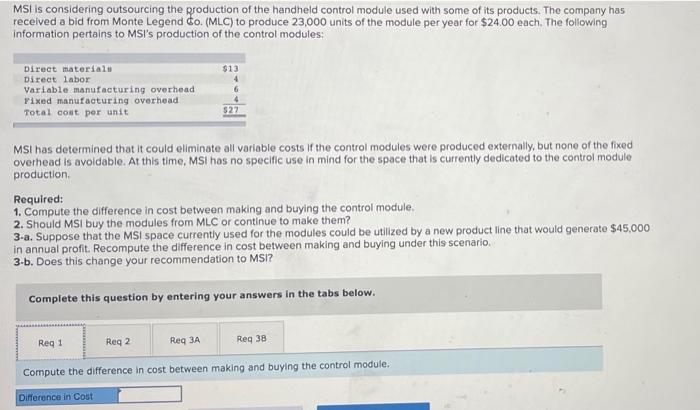

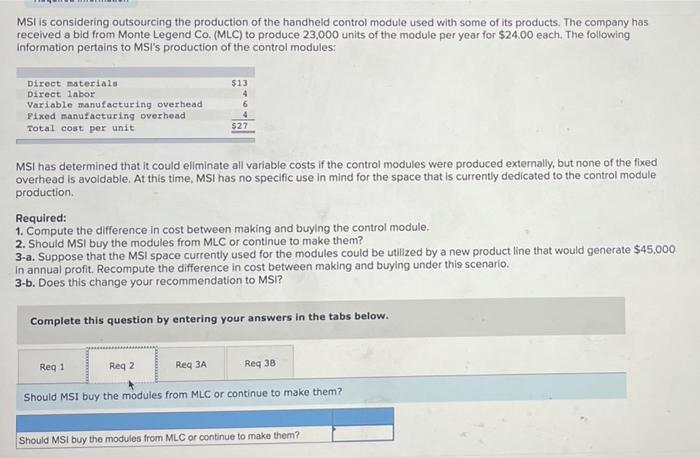

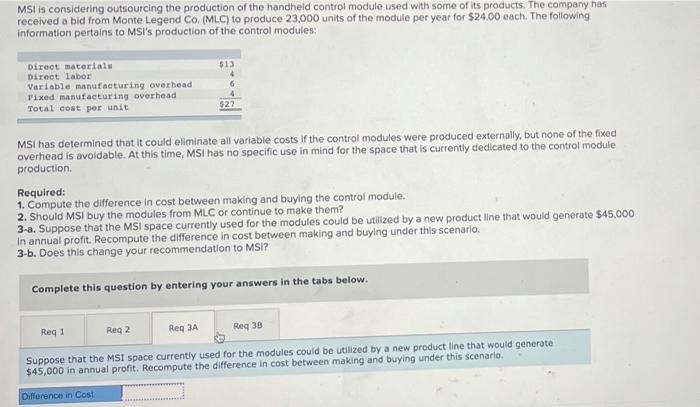

MSI is considering outsourcing the production of the handheld control module used with some of its products. The company has received a bid from Monte Legend Co. (MLC) to produce 23,000 units of the module per year for $24.00 each. The following information pertains to MSi's production of the control modules: $13 Direct materials Direct labor Variable manufacturing overhead Fixed manufacturing overhead Total cost per unit 522 MSI has determined that it could eliminate all variable costs of the control modules were produced externally, but none of the fixed overhead is avoidable. At this time, MSi hos no specific use in mind for the space that is currently dedicated to the control module production Required: 1. Compute the difference in cost between making and buying the control module. 2. Should MSI buy the modules from MLC or continue to make them? 3-a. Suppose that the MSI space currently used for the modules could be utilized by a new product line that would generato $45,000 in annual profit. Recompute the difference in cost between making and buying under this scenario. 3-b. Does this change your recommendation to MSI? Complete this question by entering your answers in the tabs below. Reg 1 Reg 2 Req 3A Reg 38 Compute the difference in cost between making and buying the control module. Difference in Cost MSI is considering outsourcing the production of the handheld control module used with some of its products. The company has received a bid from Monte Legend Co. (MLC) to produce 23,000 units of the module per year for $24.00 each. The following Information pertains to MSi's production of the control modules: $13 4 Direct materials Direct labor Variable manufacturing overhead Pixed manufacturing overhead Total cost per unit $27 MSI has determined that it could ellminate all variable costs if the control modules were produced externally, but none of the fixed overhead is avoidable. At this time, MSI has no specific use in mind for the space that is currently dedicated to the control module production Required: 1. Compute the difference in cost between making and buying the control module. 2. Should MSI buy the modules from MLC or continue to make them? 3-a. Suppose that the MSI space currently used for the modules could be utilized by a new product line that would generate $45,000 In annual profit. Recompute the difference in cost between making and buying under this scenario. 3-b. Does this change your recommendation to MSI? Complete this question by entering your answers in the tabs below. Reg 1 Reg 2 Rea Reg 3B Should MSI buy the modules from MLC or continue to make them? Should MSI buy the modules from MLC or continue to make them? MSI is considering outsourcing the production of the handheld control module used with some of its products. The company has received a bid from Monte Legend Co. (MLC) to produce 23,000 units of the module per year for $24.00 each. The following information pertains to MSI's production of the control modules: $13 Direct materials Direct labor Variable manufacturing overhead Fixed manufacturing overhead Total cost per unit 522 MSI has determined that it could eliminate all variable costs of the control modules were produced externally, but none of the fixed overhead is avoidable. At this time, MSI has no specific use in mind for the space that is currently dedicated to the control module production Required: 1. Compute the difference in cost between making and buying the control module. 2. Should MSI buy the modules from MLC or continue to make them? 3-a. Suppose that the MSI space currently used for the modules could be utilized by a new product line that would generate $45,000 in annual profit. Recompute the difference in cost between making and buying under this scenario. 3-b. Does this change your recommendation to MSI? Complete this question by entering your answers in the tabs below. Reg 1 Reg 2 Reg 3A Reg 38 Suppose that the MSI space currently used for the modules could be utilized by a new product line that would generate $45,000 in annual profit. Recompute the difference in cost between making and buying under this scenario, Difference in Cost MSI is considering outsourcing the production of the handheld control module used with some of its products. The company has received a bid from Monte Legend Co. (MLC) to produce 23,000 units of the module per year for $24.00 each. The following information pertains to MSI's production of the control modules: $13 Direct materials Direct labor Variable manufacturing overhead Fixed manufacturing overhead Total cost per unit $27 MSI has determined that it could eliminate all variable costs if the control modules were produced externally, but none of the fixed overhead is avoidable. At this time, MSI has no specific use in mind for the space that is currently dedicated to the control module production Required: 1. Compute the difference in cost between making and buying the control module. 2. Should MSI buy the modules from MLC or continue to make them? 3-a. Suppose that the MSI space currently used for the modules could be utilized by a new product line that would generate $45,000 In annual profit. Recompute the difference in cost between making and buying under this scenario. 3-b. Does this change your recommendation to MSI? Complete this question by entering your answers in the tabs below. Reg 1 Reg 2 Reg 3A Real 30 Does this change your recommendation to MS!? Does this change your recommendation to MSI