Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Need all otherwise down voted Current Purchase Policy vs JIT Purchasing N 05 X Video Company sells package of blank video tapes to its customers.

Need all otherwise down voted

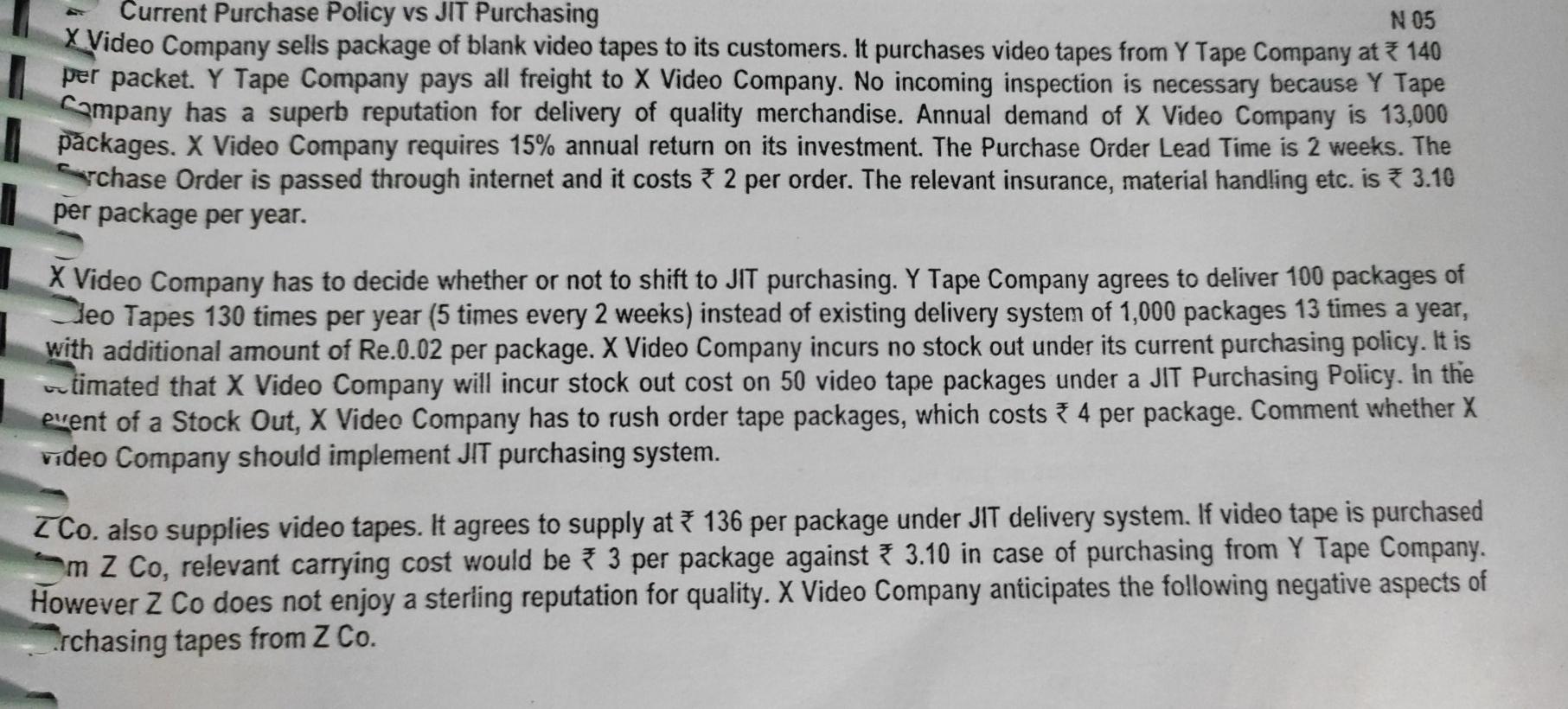

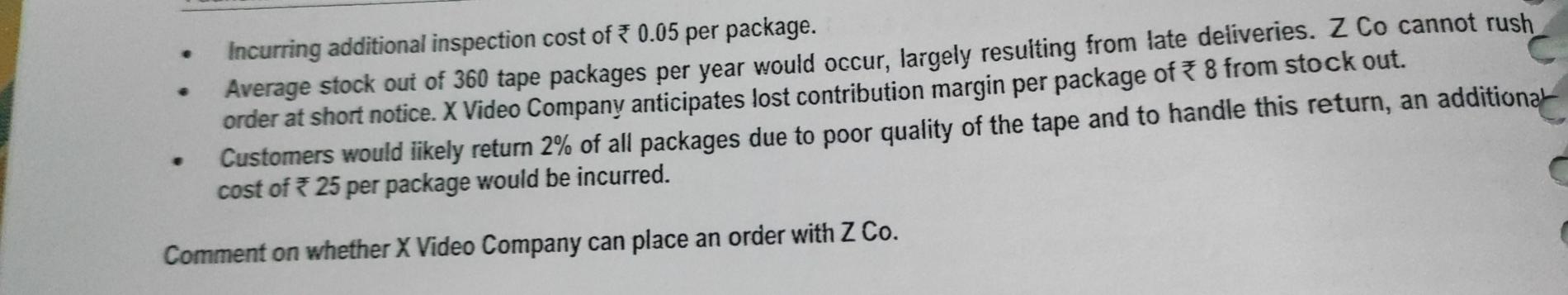

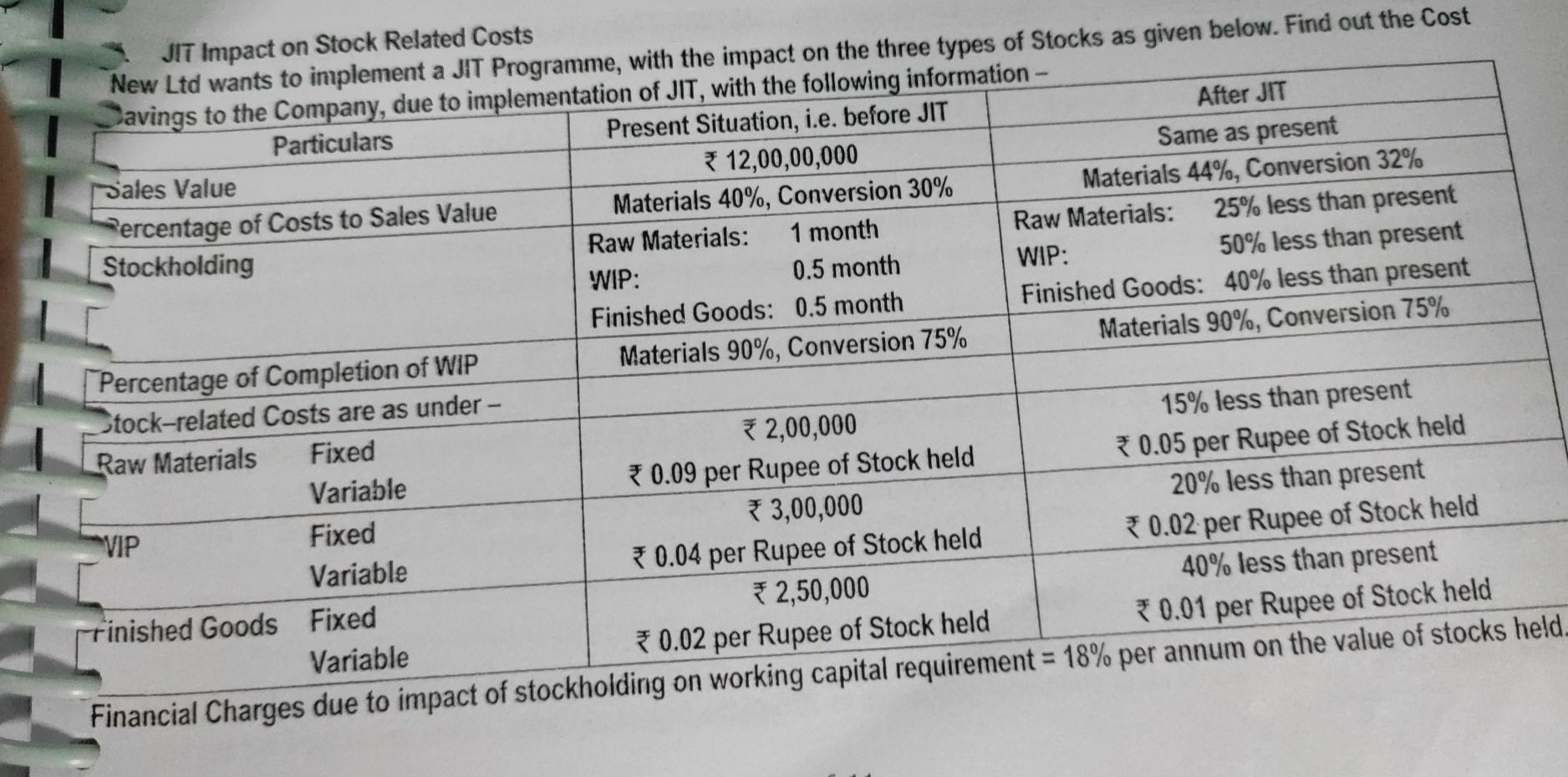

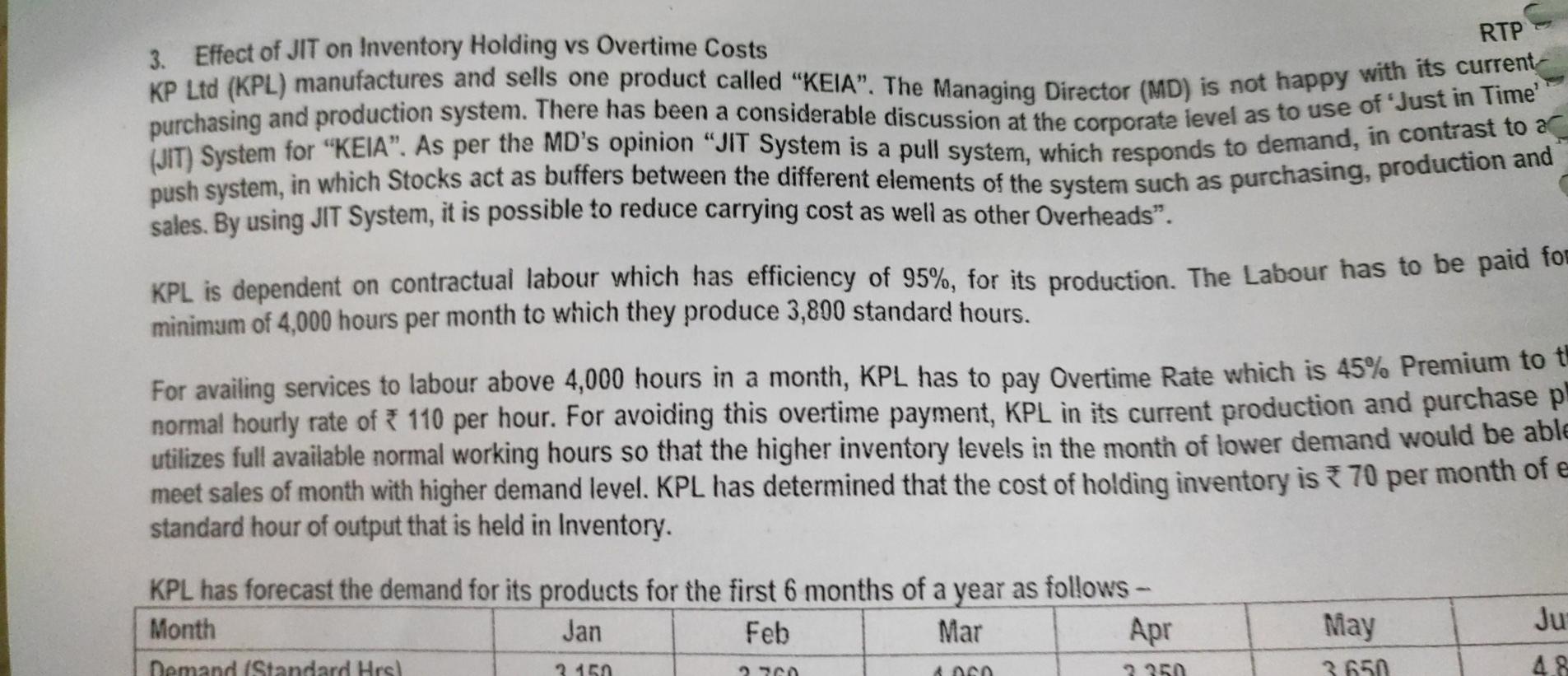

Current Purchase Policy vs JIT Purchasing N 05 X Video Company sells package of blank video tapes to its customers. It purchases video tapes from Y Tape Company at 140 per packet. Y Tape Company pays all freight to X Video Company. No incoming inspection is necessary because Y Tape Company has a superb reputation for delivery of quality merchandise. Annual demand of X Video Company is 13,000 packages. X Video Company requires 15% annual return on its investment. The Purchase Order Lead Time is 2 weeks. The Serchase Order is passed through internet and it costs * 2 per order. The relevant insurance, material handling etc. is * 3.10 per package per year. X Video Company has to decide whether or not to shift to JIT purchasing. Y Tape Company agrees to deliver 100 packages of deo Tapes 130 times per year (5 times every 2 weeks) instead of existing delivery system of 1,000 packages 13 times a year, with additional amount of Re.0.02 per package. X Video Company incurs no stock out under its current purchasing policy. It is vtimated that X Video Company will incur stock out cost on 50 video tape packages under a JIT Purchasing Policy. In the event of a Stock Out, X Video Company has to rush order tape packages, which costs 4 per package. Comment whether X video Company should implement JIT purchasing system. [Co. also supplies video tapes. It agrees to supply at * 136 per package under JIT delivery system. If video tape is purchased m Z Co, relevant carrying cost would be * 3 per package against * 3.10 in case of purchasing from Y Tape Company. However Z Co does not enjoy a sterling reputation for quality. X Video Company anticipates the following negative aspects of rchasing tapes from Z Co. Incurring additional inspection cost of 0.05 per package. Average stock out of 360 tape packages per year would occur, largely resulting from late deliveries. Z Co cannot rush order at short notice. X Video Company anticipates lost contribution margin per package of 8 from stock out. Customers would likely return 2% of all packages due to poor quality of the tape and to handle this return, an additional cost of 25 per package would be incurred. Comment on whether X Video Company can place an order with Z Co. JIT Impact on Stock Related Costs New Ltd wants to implement a JIT Programme, with the impact on the three types of Stocks as given below. Find out the Cost Davings to the Company, due to implementation of JIT, with the following information - Particulars Present Situation, i.e. before JIT After JIT Sales Value 12,00,00,000 Same as present Sercentage of Costs to Sales Value Materials 40%, Conversion 30% Materials 44%, Conversion 32% Stockholding Raw Materials: 1 month Raw Materials: 25% less than present WIP: 0.5 month WIP: 50% less than present Finished Goods: 0.5 month Finished Goods: 40% less than present Percentage of Completion of WIP Materials 90%, Conversion 75% Materials 90%, Conversion 75% Stock-related Costs are as under - Raw Materials Fixed 2,00,000 15% less than present Variable 0.09 per Rupee of Stock held 0.05 per Rupee of Stock held Fixed 3,00,000 20% less than present Variable 0.04 per Rupee of Stock held 0.02 per Rupee of Stock held Tinished Goods Fixed *2,50,000 40% less than present Variable 0.02 per Rupee of Stock held *0.01 per Rupee of Stock held Financial Charges due to impact of stockholding on working capital requirement = 18% per annum on the value of stocks held. VIP RTP 3. Effect of JIT on Inventory Holding vs Overtime Costs KP Led (KPL) manufactures and sells one product called "KEIA. The Managing Director (MD) is not happy with its current purchasing and production system. There has been a considerable discussion at the corporate level as to use of "Just in Time JIT) System for KEIA. As per the MD's opinion JIT System is a pull system, which responds to demand, in contrast tona push system, in which Stocks act as buffers between the different elements of the system such as purchasing, production and sales. By using JIT System, it is possible to reduce carrying cost as well as other Overheads. KPL is dependent on contractual labour which has efficiency of 95%, for its production. The Labour has to be paid for minimum of 4,000 hours per month to which they produce 3,800 standard hours. For availing services to labour above 4,000 hours in a month, KPL has to pay Overtime Rate which is 45% Premium to t normal hourly rate of * 110 per hour. For avoiding this overtime payment, KPL in its current production and purchase pl utilizes full available normal working hours so that the higher inventory levels in the month of lower demand would be able meet sales of month with higher demand level. KPL has determined that the cost of holding inventory is 370 per month of e standard hour of output that is held in Inventory. KPL has forecast the demand for its products for the first 6 months of a year as follows - Month Jan Feb Mar Apr Ju May 3650 Demand (Standard Hrs) 3. 150 2 6S 2350 4.8Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started