need answer:

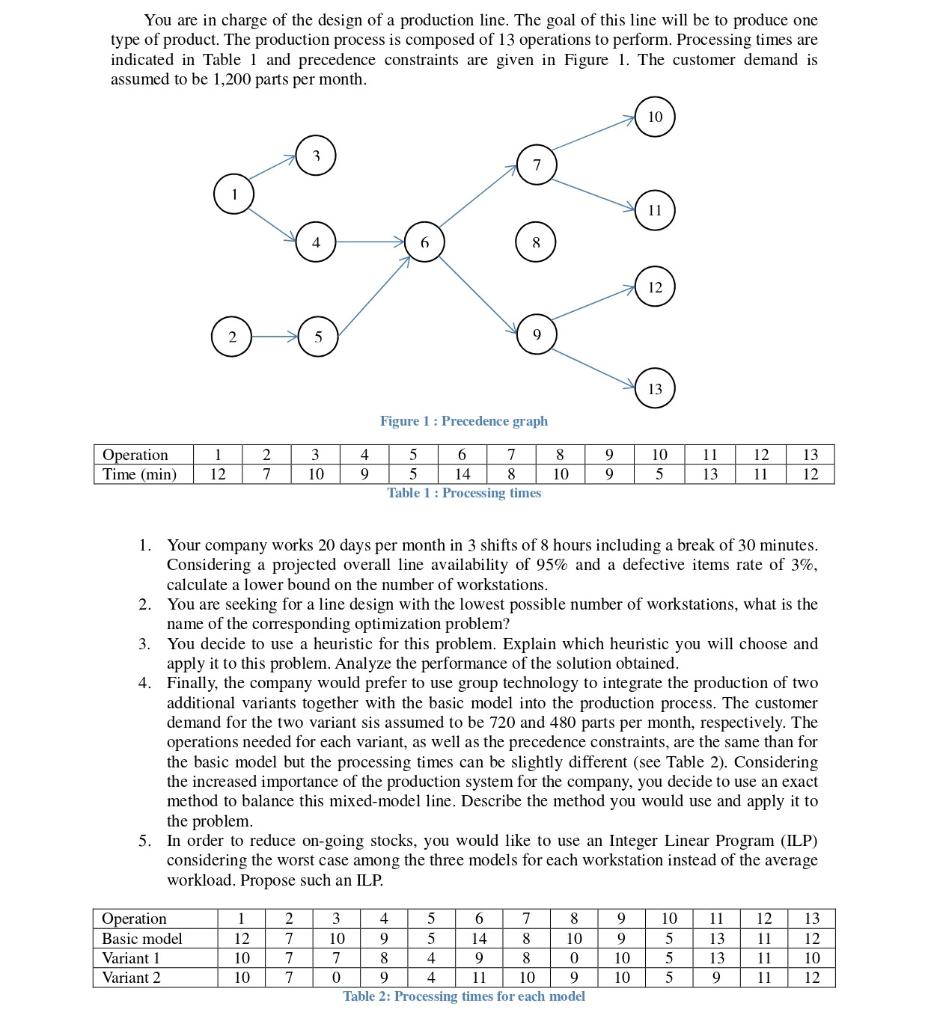

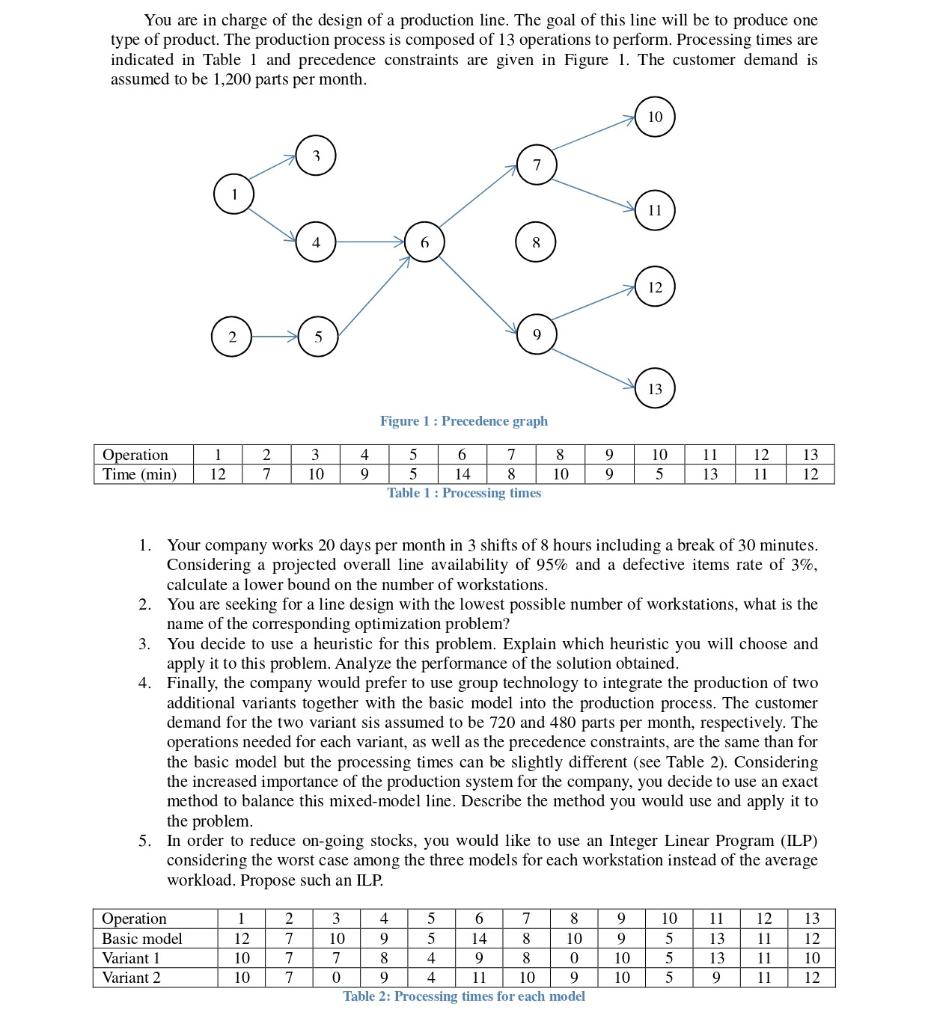

You are in charge of the design of a production line. The goal of this line will be to produce one type of product. The production process is composed of 13 operations to perform. Processing times are indicated in Table 1 and precedence constraints are given in Figure 1. The customer demand is assumed to be 1,200 parts per month. Figure 1 : Precedence graph 1. Your company works 20 days per month in 3 shifts of 8 hours including a break of 30 minutes. Considering a projected overall line availability of 95% and a defective items rate of 3%, calculate a lower bound on the number of workstations. 2. You are seeking for a line design with the lowest possible number of workstations, what is the name of the corresponding optimization problem? 3. You decide to use a heuristic for this problem. Explain which heuristic you will choose and apply it to this problem. Analyze the performance of the solution obtained. 4. Finally, the company would prefer to use group technology to integrate the production of two additional variants together with the basic model into the production process. The customer demand for the two variant sis assumed to be 720 and 480 parts per month, respectively. The operations needed for each variant, as well as the precedence constraints, are the same than for the basic model but the processing times can be slightly different (see Table 2). Considering the increased importance of the production system for the company, you decide to use an exact method to balance this mixed-model line. Describe the method you would use and apply it to the problem. 5. In order to reduce on-going stocks, you would like to use an Integer Linear Program (ILP) considering the worst case among the three models for each workstation instead of the average workload. Propose such an ILP. Table z: l'rocessing tumes tor each model You are in charge of the design of a production line. The goal of this line will be to produce one type of product. The production process is composed of 13 operations to perform. Processing times are indicated in Table 1 and precedence constraints are given in Figure 1. The customer demand is assumed to be 1,200 parts per month. Figure 1 : Precedence graph 1. Your company works 20 days per month in 3 shifts of 8 hours including a break of 30 minutes. Considering a projected overall line availability of 95% and a defective items rate of 3%, calculate a lower bound on the number of workstations. 2. You are seeking for a line design with the lowest possible number of workstations, what is the name of the corresponding optimization problem? 3. You decide to use a heuristic for this problem. Explain which heuristic you will choose and apply it to this problem. Analyze the performance of the solution obtained. 4. Finally, the company would prefer to use group technology to integrate the production of two additional variants together with the basic model into the production process. The customer demand for the two variant sis assumed to be 720 and 480 parts per month, respectively. The operations needed for each variant, as well as the precedence constraints, are the same than for the basic model but the processing times can be slightly different (see Table 2). Considering the increased importance of the production system for the company, you decide to use an exact method to balance this mixed-model line. Describe the method you would use and apply it to the problem. 5. In order to reduce on-going stocks, you would like to use an Integer Linear Program (ILP) considering the worst case among the three models for each workstation instead of the average workload. Propose such an ILP. Table z: l'rocessing tumes tor each model