Answered step by step

Verified Expert Solution

Question

1 Approved Answer

need help this is my last question usage please to explain the rules I know i just really need help with this. Which of the

need help this is my last question usage please to explain the rules I know i just really need help with this.

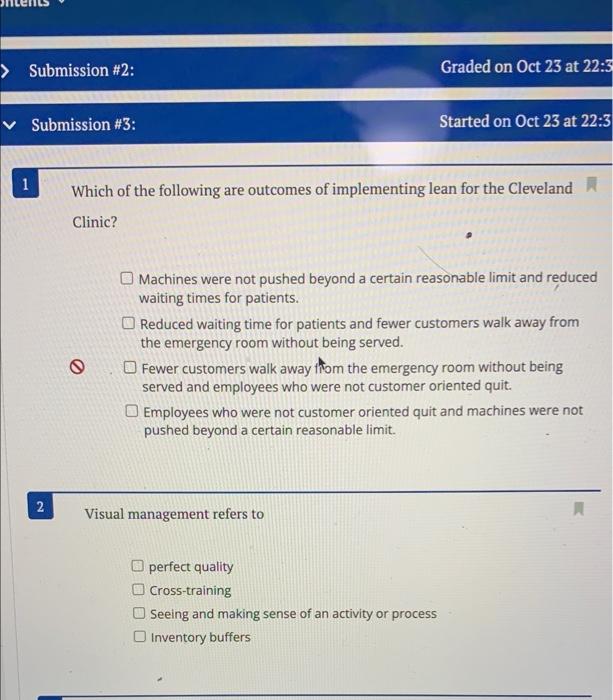

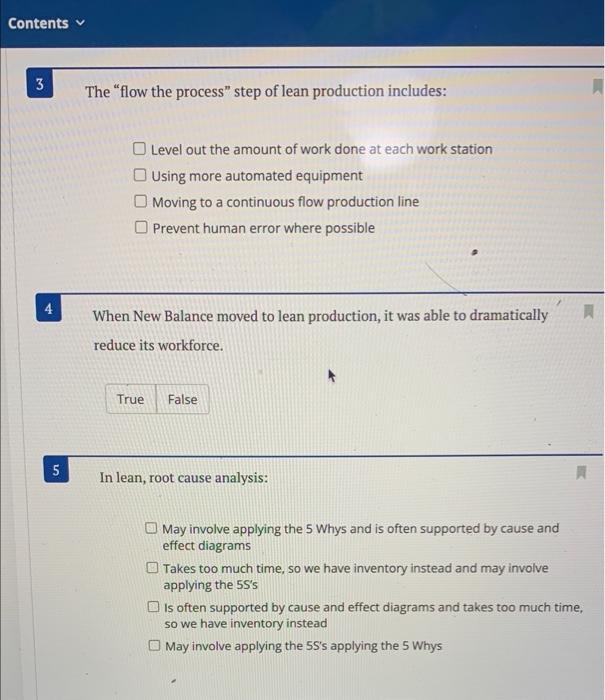

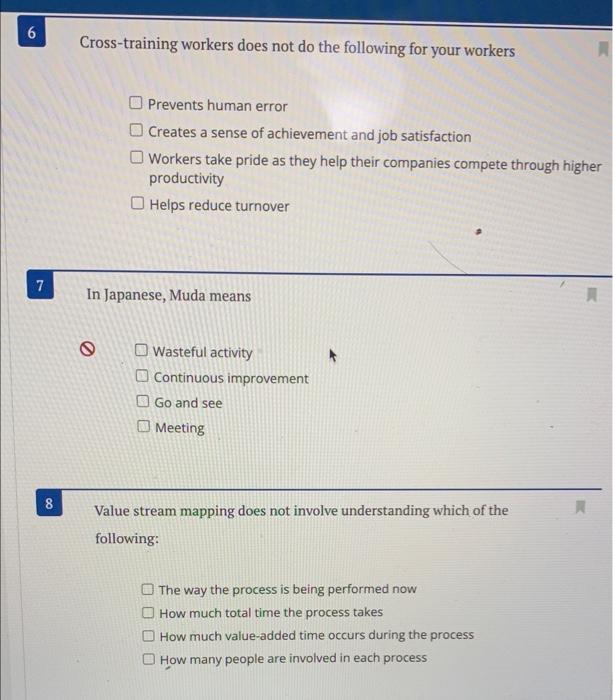

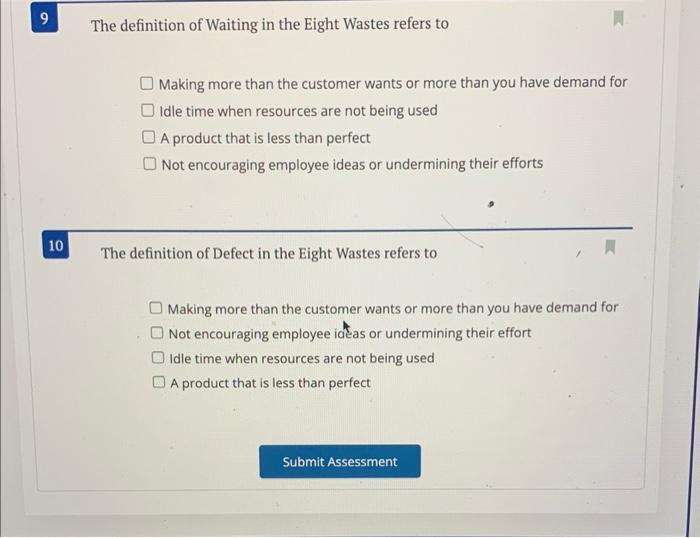

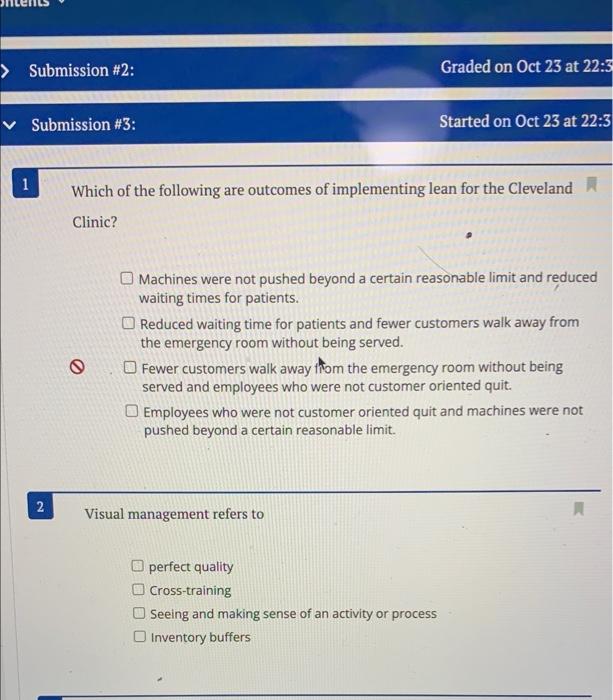

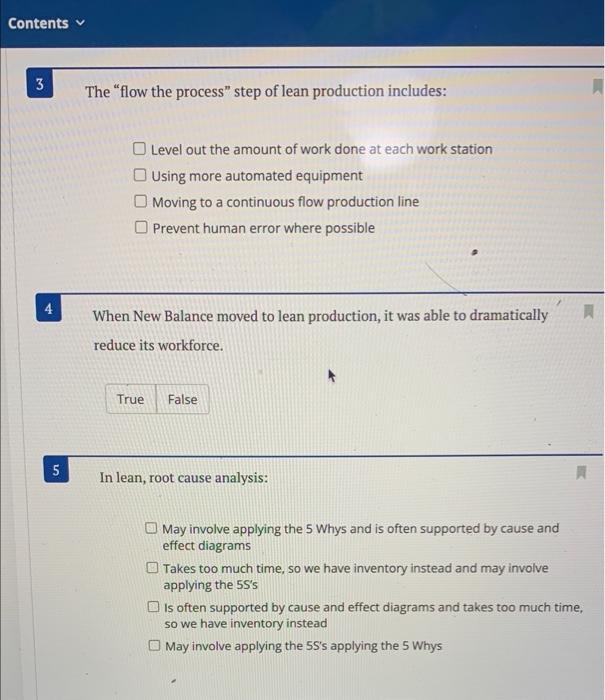

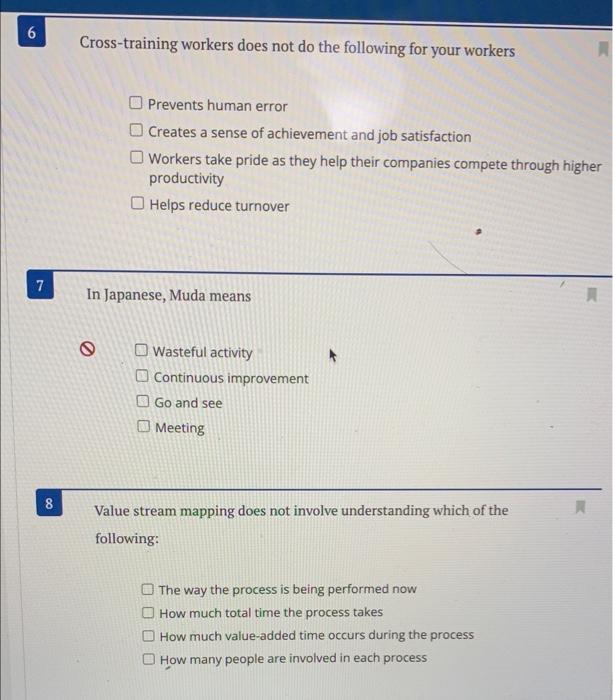

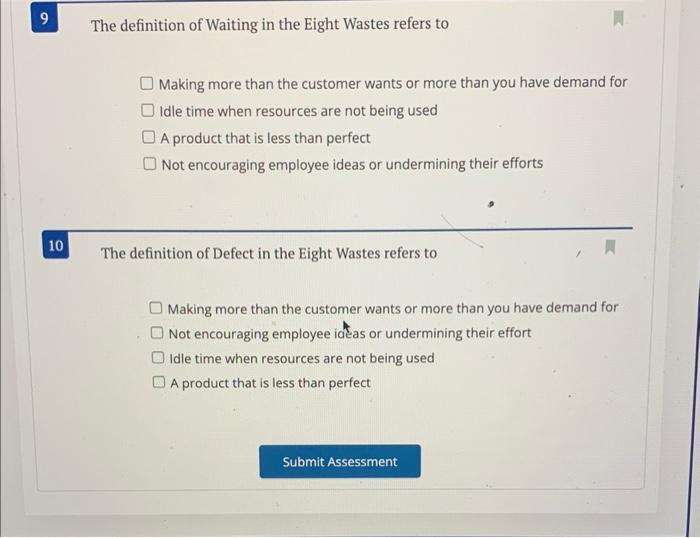

Which of the following are outcomes of implementing lean for the Cleveland Clinic? Machines were not pushed beyond a certain reasonable limit and reduced waiting times for patients. Reduced waiting time for patients and fewer customers walk away from the emergency room without being served. Fewer customers walk away fhom the emergency room without being served and employees who were not customer oriented quit. Employees who were not customer oriented quit and machines were not pushed beyond a certain reasonable limit. 2 Visual management refers to perfect quality Cross-training Seeing and making sense of an activity or process Inventory buffers The "flow the process" step of lean production includes: Level out the amount of work done at each work station Using more automated equipment Moving to a continuous flow production line Prevent human error where possible When New Balance moved to lean production, it was able to dramatically reduce its workforce. In lean, root cause analysis: May involve applying the 5 Whys and is often supported by cause and effect diagrams Takes too much time, so we have inventory instead and may involve applying the 5 S's Is often supported by cause and effect diagrams and takes too much time, so we have inventory instead May involve applying the 5S 's applying the 5 Whys Cross-training workers does not do the following for your workers Prevents human error Creates a sense of achievement and job satisfaction Workers take pride as they help their companies compete through higher productivity Helps reduce turnover 7 In Japanese, Muda means Wasteful activity Continuous improvement Go and see Meeting 8 Value stream mapping does not involve understanding which of the following: The way the process is being performed now How much total time the process takes How much value-added time occurs during the process How many people are involved in each process The definition of Waiting in the Eight Wastes refers to Making more than the customer wants or more than you have demand for Idle time when resources are not being used A product that is less than perfect Not encouraging employee ideas or undermining their efforts The definition of Defect in the Eight Wastes refers to Making more than the customer wants or more than you have demand for Not encouraging employee ideas or undermining their effort Idle time when resources are not being used A product that is less than perfect Which of the following are outcomes of implementing lean for the Cleveland Clinic? Machines were not pushed beyond a certain reasonable limit and reduced waiting times for patients. Reduced waiting time for patients and fewer customers walk away from the emergency room without being served. Fewer customers walk away fhom the emergency room without being served and employees who were not customer oriented quit. Employees who were not customer oriented quit and machines were not pushed beyond a certain reasonable limit. 2 Visual management refers to perfect quality Cross-training Seeing and making sense of an activity or process Inventory buffers The "flow the process" step of lean production includes: Level out the amount of work done at each work station Using more automated equipment Moving to a continuous flow production line Prevent human error where possible When New Balance moved to lean production, it was able to dramatically reduce its workforce. In lean, root cause analysis: May involve applying the 5 Whys and is often supported by cause and effect diagrams Takes too much time, so we have inventory instead and may involve applying the 5 S's Is often supported by cause and effect diagrams and takes too much time, so we have inventory instead May involve applying the 5S 's applying the 5 Whys Cross-training workers does not do the following for your workers Prevents human error Creates a sense of achievement and job satisfaction Workers take pride as they help their companies compete through higher productivity Helps reduce turnover 7 In Japanese, Muda means Wasteful activity Continuous improvement Go and see Meeting 8 Value stream mapping does not involve understanding which of the following: The way the process is being performed now How much total time the process takes How much value-added time occurs during the process How many people are involved in each process The definition of Waiting in the Eight Wastes refers to Making more than the customer wants or more than you have demand for Idle time when resources are not being used A product that is less than perfect Not encouraging employee ideas or undermining their efforts The definition of Defect in the Eight Wastes refers to Making more than the customer wants or more than you have demand for Not encouraging employee ideas or undermining their effort Idle time when resources are not being used A product that is less than perfect

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started