Question: need help with activity based costing ACC 350 2/7/22 orf Road Trucks Case Introduction Off Road Trucks (ORT) has developed a new truck, the Eco

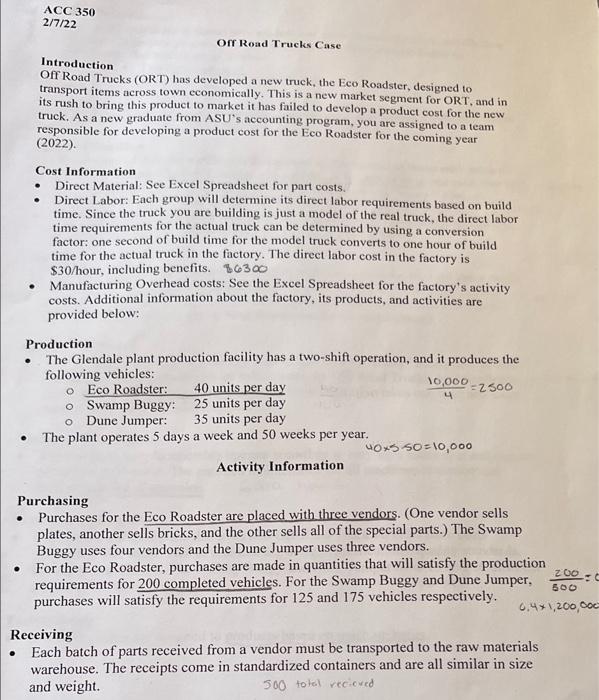

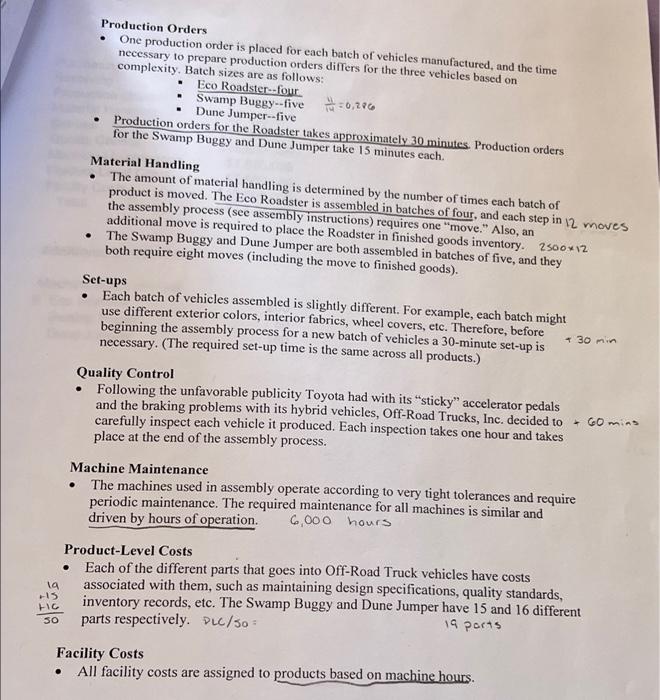

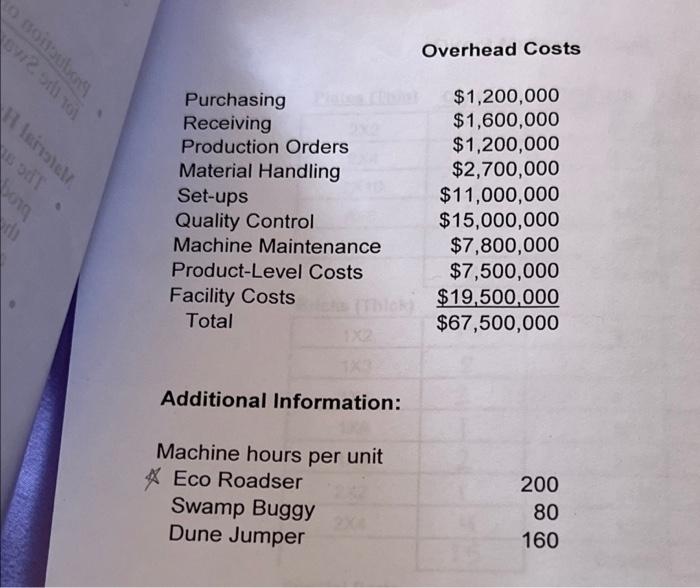

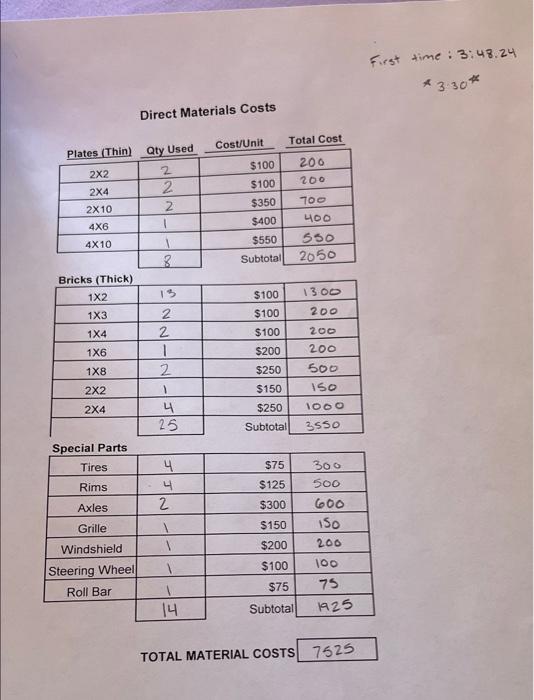

ACC 350 2/7/22 orf Road Trucks Case Introduction Off Road Trucks (ORT) has developed a new truck, the Eco Roadster, designed to transport items across town economically. This is a new market segment for ORT, and in its rush to bring this product to market it has failed to develop a product cost for the new truck. As a new graduate from ASU's accounting program, you are assigned to a team responsible for developing a product cost for the Eco Roadster for the coming year (2022) Cost Information Direct Material: See Excel Spreadsheet for part costs. Direct Labor: Each group will determine its direct labor requirements based on build time. Since the truck you are building is just a model of the real truck, the direct labor time requirements for the actual truck can be determined by using a conversion factor: one second of build time for the model truck converts to one hour of build time for the actual truck in the factory. The direct labor cost in the factory is $30/hour, including benefits. 16300 Manufacturing Overhead costs: See the Excel Spreadsheet for the factory's activity costs. Additional information about the factory, its products, and activities are provided below: Production The Glendale plant production facility has a two-shift operation, and it produces the following vehicles: 10,000 o Eco Roadster: 40 units per day -2500 o Swamp Buggy: 25 units per day Dune Jumper: 35 units per day The plant operates 5 days a week and 50 weeks per year. 40x5 50 510,000 Activity Information 4 200: 500 Purchasing Purchases for the Eco Roadster are placed with three vendors. (One vendor sells plates, another sells bricks, and the other sells all of the special parts.) The Swamp Buggy uses four vendors and the Dune Jumper uses three vendors. For the Eco Roadster, purchases are made in quantities that will satisfy the production requirements for 200 completed vehicles. For the Swamp Buggy and Dune Jumper, purchases will satisfy the requirements for 125 and 175 vehicles respectively. 6.4% 1,200,000 Receiving Each batch of parts received from a vendor must be transported to the raw materials warehouse. The receipts come in standardized containers and are all similar in size and weight. 500 total recieved Production Orders One production order is placed for each batch of vehicles manufactured, and the time necessary to prepare production orders differs for the three vehicles based on complexity. Batch sizes are as follows: Eco Roadster--four Swamp Buggy--five =0,286 Dune Jumper--five Production orders for the Roadster takes approximately 30 minutes. Production orders for the Swamp Buggy and Dune Jumper take 15 minutes each. Material Handling The amount of material handling is determined by the number of times each batch of product is moved. The Eco Roadster is assembled in batches of four, and each step in 12 moves the assembly process (see assembly instructions) requires one "move." Also, an additional move is required to place the Roadster in finished goods inventory. 2500*12 The Swamp Buggy and Dune Jumper are both assembled in batches of five, and they both require eight moves (including the move to finished goods). . + 30 min Set-ups Each batch of vehicles assembled is slightly different. For example, each batch might use different exterior colors, interior fabrics, wheel covers, etc. Therefore, before beginning the assembly process for a new batch of vehicles a 30-minute set-up is necessary. (The required set-up time is the same across all products.) Quality Control Following the unfavorable publicity Toyota had with its sticky" accelerator pedals and the braking problems with its hybrid vehicles, Off-Road Trucks, Inc. decided to - 60 mins carefully inspect each vehicle it produced. Each inspection takes one hour and takes place at the end of the assembly process. Machine Maintenance The machines used in assembly operate according to very tight tolerances and require periodic maintenance. The required maintenance for all machines is similar and driven by hours of operation. 6,000 hours Product-Level Costs Each of the different parts that goes into Off-Road Truck vehicles have costs associated with them, such as maintaining design specifications, quality standards, inventory records, etc. The Swamp Buggy and Dune Jumper have 15 and 16 different parts respectively. DLC/50 19 ports 19 -15 HIC SO Facility Costs All facility costs are assigned to products based on machine hours. . Overhead Costs OLD Hell bu Purchasing Receiving Production Orders Material Handling Set-ups Quality Control Machine Maintenance Product-Level Costs Facility Costs Total $1,200,000 $1,600,000 $1,200,000 $2,700,000 $11,000,000 $15,000,000 $7,800,000 $7,500,000 $19,500,000 $67,500,000 Additional Information: Machine hours per unit A Eco Roadser Swamp Buggy Dune Jumper 200 80 160 First time: 3:48.24 *3.30* Direct Materials Costs Cost/Unit Total Cost Plates (Thin) 2x2 2X4 2X 10 4X6 Qty Used 2 2 2 1 $100 $100 $350 200 200 700 400 350 2050 $400 4X10 $550 Subtotal 8 13 $100 1300 Bricks (Thick) 1X2 1X3 1X4 1X6 $100 200 2 2 $100 $200 1X8 $250 200 200 500 150 1000 2X2 2 1 4 25 $150 2X4 $250 Subtotal 355o Special Parts Tires $75 Rims 4 2 $125 Axles $300 300 500 600 150 200 $150 $200 Grille Windshield Steering Wheel Roll Bar $100 100 $75 75 14 Subtotal 1925 TOTAL MATERIAL COSTS 7525 ACC 350 2/7/22 orf Road Trucks Case Introduction Off Road Trucks (ORT) has developed a new truck, the Eco Roadster, designed to transport items across town economically. This is a new market segment for ORT, and in its rush to bring this product to market it has failed to develop a product cost for the new truck. As a new graduate from ASU's accounting program, you are assigned to a team responsible for developing a product cost for the Eco Roadster for the coming year (2022) Cost Information Direct Material: See Excel Spreadsheet for part costs. Direct Labor: Each group will determine its direct labor requirements based on build time. Since the truck you are building is just a model of the real truck, the direct labor time requirements for the actual truck can be determined by using a conversion factor: one second of build time for the model truck converts to one hour of build time for the actual truck in the factory. The direct labor cost in the factory is $30/hour, including benefits. 16300 Manufacturing Overhead costs: See the Excel Spreadsheet for the factory's activity costs. Additional information about the factory, its products, and activities are provided below: Production The Glendale plant production facility has a two-shift operation, and it produces the following vehicles: 10,000 o Eco Roadster: 40 units per day -2500 o Swamp Buggy: 25 units per day Dune Jumper: 35 units per day The plant operates 5 days a week and 50 weeks per year. 40x5 50 510,000 Activity Information 4 200: 500 Purchasing Purchases for the Eco Roadster are placed with three vendors. (One vendor sells plates, another sells bricks, and the other sells all of the special parts.) The Swamp Buggy uses four vendors and the Dune Jumper uses three vendors. For the Eco Roadster, purchases are made in quantities that will satisfy the production requirements for 200 completed vehicles. For the Swamp Buggy and Dune Jumper, purchases will satisfy the requirements for 125 and 175 vehicles respectively. 6.4% 1,200,000 Receiving Each batch of parts received from a vendor must be transported to the raw materials warehouse. The receipts come in standardized containers and are all similar in size and weight. 500 total recieved Production Orders One production order is placed for each batch of vehicles manufactured, and the time necessary to prepare production orders differs for the three vehicles based on complexity. Batch sizes are as follows: Eco Roadster--four Swamp Buggy--five =0,286 Dune Jumper--five Production orders for the Roadster takes approximately 30 minutes. Production orders for the Swamp Buggy and Dune Jumper take 15 minutes each. Material Handling The amount of material handling is determined by the number of times each batch of product is moved. The Eco Roadster is assembled in batches of four, and each step in 12 moves the assembly process (see assembly instructions) requires one "move." Also, an additional move is required to place the Roadster in finished goods inventory. 2500*12 The Swamp Buggy and Dune Jumper are both assembled in batches of five, and they both require eight moves (including the move to finished goods). . + 30 min Set-ups Each batch of vehicles assembled is slightly different. For example, each batch might use different exterior colors, interior fabrics, wheel covers, etc. Therefore, before beginning the assembly process for a new batch of vehicles a 30-minute set-up is necessary. (The required set-up time is the same across all products.) Quality Control Following the unfavorable publicity Toyota had with its sticky" accelerator pedals and the braking problems with its hybrid vehicles, Off-Road Trucks, Inc. decided to - 60 mins carefully inspect each vehicle it produced. Each inspection takes one hour and takes place at the end of the assembly process. Machine Maintenance The machines used in assembly operate according to very tight tolerances and require periodic maintenance. The required maintenance for all machines is similar and driven by hours of operation. 6,000 hours Product-Level Costs Each of the different parts that goes into Off-Road Truck vehicles have costs associated with them, such as maintaining design specifications, quality standards, inventory records, etc. The Swamp Buggy and Dune Jumper have 15 and 16 different parts respectively. DLC/50 19 ports 19 -15 HIC SO Facility Costs All facility costs are assigned to products based on machine hours. . Overhead Costs OLD Hell bu Purchasing Receiving Production Orders Material Handling Set-ups Quality Control Machine Maintenance Product-Level Costs Facility Costs Total $1,200,000 $1,600,000 $1,200,000 $2,700,000 $11,000,000 $15,000,000 $7,800,000 $7,500,000 $19,500,000 $67,500,000 Additional Information: Machine hours per unit A Eco Roadser Swamp Buggy Dune Jumper 200 80 160 First time: 3:48.24 *3.30* Direct Materials Costs Cost/Unit Total Cost Plates (Thin) 2x2 2X4 2X 10 4X6 Qty Used 2 2 2 1 $100 $100 $350 200 200 700 400 350 2050 $400 4X10 $550 Subtotal 8 13 $100 1300 Bricks (Thick) 1X2 1X3 1X4 1X6 $100 200 2 2 $100 $200 1X8 $250 200 200 500 150 1000 2X2 2 1 4 25 $150 2X4 $250 Subtotal 355o Special Parts Tires $75 Rims 4 2 $125 Axles $300 300 500 600 150 200 $150 $200 Grille Windshield Steering Wheel Roll Bar $100 100 $75 75 14 Subtotal 1925 TOTAL MATERIAL COSTS 7525

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts