Question: Need help with solving the given questions 10. A manufacturer is contemplating the purchase of a punch press. Approximately 10,000 units are processed on the

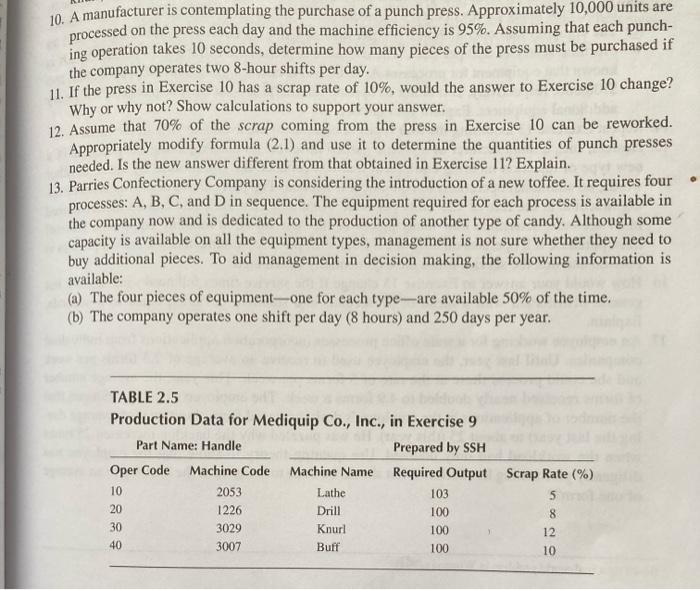

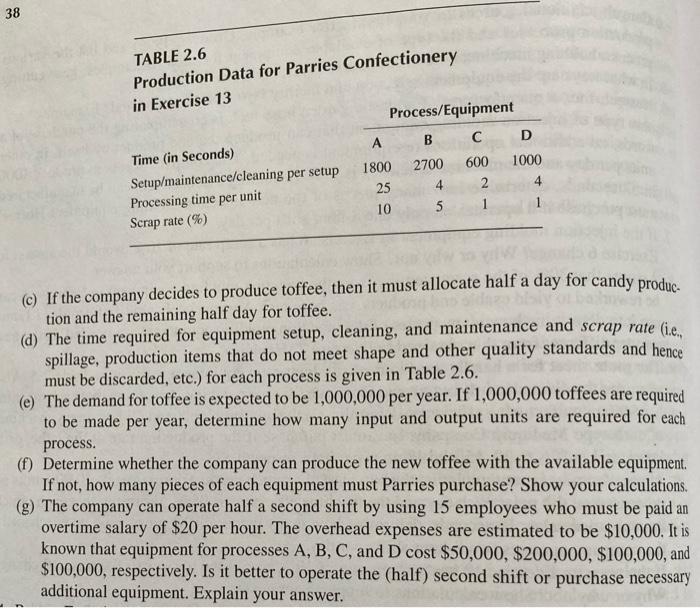

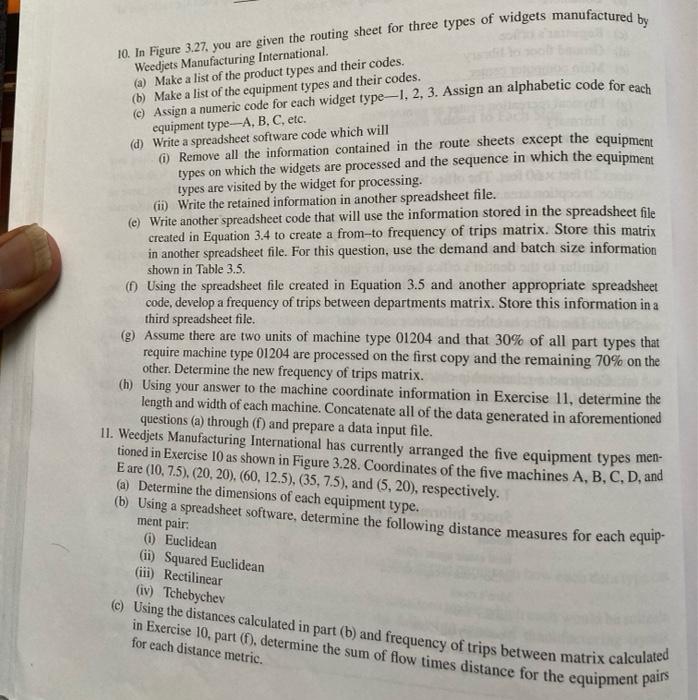

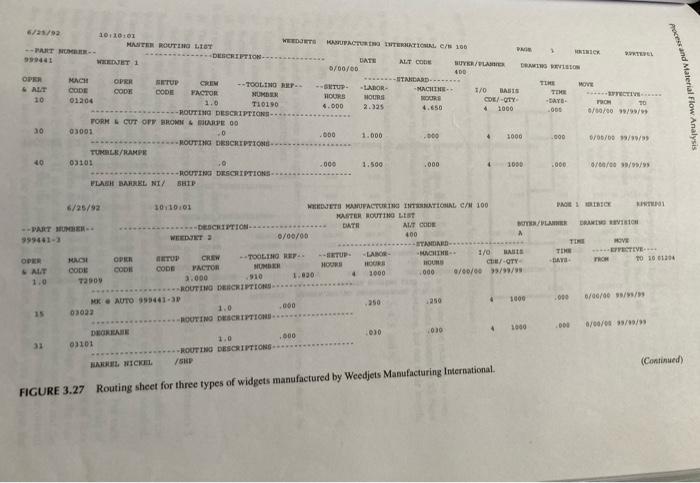

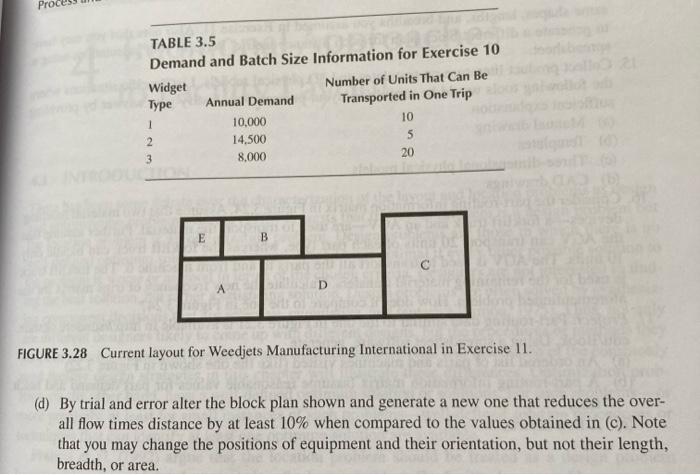

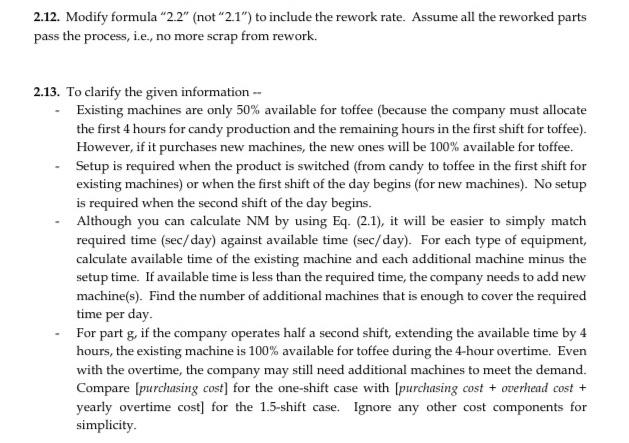

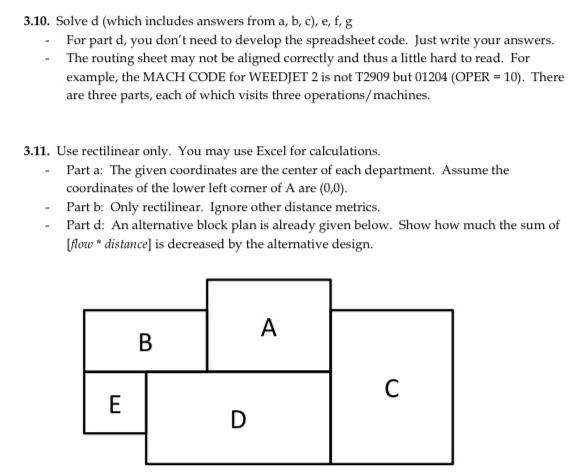

10. A manufacturer is contemplating the purchase of a punch press. Approximately 10,000 units are processed on the press each day and the machine efficiency is 95%. Assuming that each punching operation takes 10 seconds, determine how many pieces of the press must be purchased if the company operates two 8 -hour shifts per day. 11. If the press in Exercise 10 has a scrap rate of 10%, would the answer to Exercise 10 change? Why or why not? Show calculations to support your answer. 12. Assume that 70% of the scrap coming from the press in Exercise 10 can be reworked. Appropriately modify formula (2.1) and use it to determine the quantities of punch presses needed. Is the new answer different from that obtained in Exercise 11? Explain. 13. Parries Confectionery Company is considering the introduction of a new toffee. It requires four processes: A, B, C, and D in sequence. The equipment required for each process is available in the company now and is dedicated to the production of another type of candy. Although some capacity is available on all the equipment types, management is not sure whether they need to buy additional pieces. To aid management in decision making, the following information is available: (a) The four pieces of equipment-one for each type-are available 50% of the time. (b) The company operates one shift per day ( 8 hours) and 250 days per year. TABLE 2.5 Production Data for Mediquip Co., Inc., in Exercise 9 TABLE 2.6 Production Data for Parries Confectionery (c) If the company decides to produce toffee, then it must allocate half a day for candy production and the remaining half day for toffee. (d) The time required for equipment setup, cleaning, and maintenance and scrap rate (i.e., spillage, production items that do not meet shape and other quality standards and hence must be discarded, etc.) for each process is given in Table 2.6. (e) The demand for toffee is expected to be 1,000,000 per year. If 1,000,000 toffees are required to be made per year, determine how many input and output units are required for each process. (f) Determine whether the company can produce the new toffee with the available equipment. If not, how many pieces of each equipment must Parries purchase? Show your calculations. (g) The company can operate half a second shift by using 15 employees who must be paid an overtime salary of $20 per hour. The overhead expenses are estimated to be $10,000. It is known that equipment for processes A,B,C, and D cost $50,000,$200,000,$100,000, and $100,000, respectively. Is it better to operate the (half) second shift or purchase necessary additional equipment. Explain your answer. 10. In Figure 3.27, you are given the routing sheet for three types of widgets manufactured by Weedjets Manufacturing International. (a) Make a list of the product types and their codes. (b) Make a list of the equipment types and their codes. (c) Acsign a numeric code for each widget type-1,2,3. Assign an alphabetic code for each equipment type-A, B, C, etc. (d) Write a spreadsheet software code which will (i) Remove all the information contained in the route sheets except the equipment types on which the widgets are processed and the sequence in which the equipment types are visited by the widget for processing. (ii) Write the retained information in another spreadsheet file. (e) Write another spreadsheet code that will use the information stored in the spreadsheet file created in Equation 3.4 to create a from-to frequency of trips matrix. Store this matrix in another spreadsheet file. For this question, use the demand and batch size information shown in Table 3.5. (f) Using the spreadsheet file created in Equation 3.5 and another appropriate spreadsheet code, develop a frequency of trips between departments matrix. Store this information in a third spreadsheet file. (g) Assume there are two units of machine type 01204 and that 30% of all part types that require machine type 01204 are processed on the first copy and the remaining 70% on the other. Determine the new frequency of trips matrix. (h) Using your answer to the machine coordinate information in Exercise 11, determine the length and width of cach machine. Concatenate all of the data generated in aforementioned questions (a) through (f) and prepare a data input file. 11. Weedjets Manufacturing International has currently arranged the five equipment types mentioned in Exercise 10 as shown in Figure 3.28. Coordinates of the five machines A, B, C, D, and E are (10,7.5),(20,20),(60,12.5),(35,7.5), and (5,20), respectively. (a) Determine the dimensions of each equipment type. (b) Using a spreadsheet software, determine the following distance measures for each equipment pair: (i) Euclidean (ii) Squared Euclidean (iii) Rectilinear (iv) Tchebychev (c) Using the distances calculated in part (b) and frequency of trips between matrix calculated in Exercise 10 , part (f), determine the sum of flow times distance for the equipment pairs FIGURE 3.27 Routing sheet for three types of widgets manufactured by Weedjets Manutacturung TABLE 3.5 Demand and Batch Size Information for Exercise 10 IGURE 3.28 Current layout for Weedjets Manufacturing International in Exercise 11. (d) By trial and error alter the block plan shown and generate a new one that reduces the overall flow times distance by at least 10% when compared to the values obtained in (c). Note that you may change the positions of equipment and their orientation, but not their length, breadth, or area. 2.12. Modify formula " 2.2( not " "1 ) to include the rework rate. Assume all the reworked parts pass the process, i.e., no more scrap from rework. 2.13. To clarify the given information - - Existing machines are only 50% available for toffee (because the company must allocate the first 4 hours for candy production and the remaining hours in the first shift for toffee). However, if it purchases new machines, the new ones will be 100% available for toffee. - Setup is required when the product is switched (from candy to toffee in the first shift for existing machines) or when the first shift of the day begins (for new machines). No setup is required when the second shift of the day begins. - Although you can calculate NM by using Eq. (2.1), it will be easier to simply match required time (sec/day) against available time (sec/day). For each type of equipment, calculate available time of the existing machine and each additional machine minus the setup time. If available time is less than the required time, the company needs to add new machine(s). Find the number of additional machines that is enough to cover the required time per day. - For part g, if the company operates half a second shift, extending the available time by 4 hours, the existing machine is 100% available for toffee during the 4-hour overtime. Even with the overtime, the company may still need additional machines to meet the demand. Compare [purchasing cost] for the one-shift case with [purchasing cost + overhend cost + yearly overtime cost] for the 1.5-shift case. Ignore any other cost components for simplicity. 3.10. Solve d (which includes answers from a,b,c ), e, f,g - For part d, you don't need to develop the spreadsheet code. Just write your answers. - The routing sheet may not be aligned correctly and thus a little hard to read. For example, the MACH CODE for WEEDJET 2 is not T2909 but 01204(OPER=10). There are three parts, each of which visits three operations/machines. 3.11. Use rectilinear only. You may use Excel for calculations. - Part a: The given coordinates are the center of each department. Assume the coordinates of the lower left corner of A are (0,0). - Part b: Only rectilinear. Ignore other distance metrics. - Part d: An alternative block plan is already given below. Show how much the sum of [flow * distance] is decreased by the alternative design

Step by Step Solution

There are 3 Steps involved in it

To solve these questions lets go stepbystep for Exercises 10 11 12 and 13 Exercise 10 Objective Determine how many punch presses to purchase Given Uni... View full answer

Get step-by-step solutions from verified subject matter experts