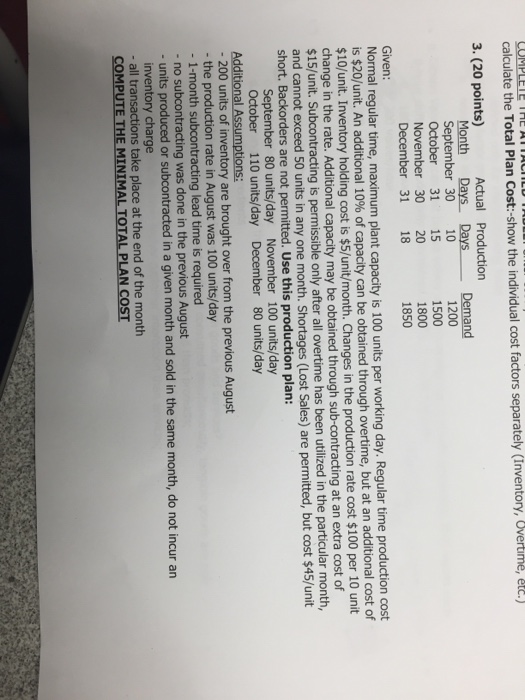

Normal regular time, maximum plant capacity is 100 units per working day. Regular time production cost is $20/unit. An additional 10% of capacity can be obtained through overtime, but at an additional cost of $10/unit. Inventory holding cost is $5/unit/month. Changes in the production rate cost $100 per 10 unit change in the rate. Additional capacity may be obtained through sub-contracting at an extra cost of $15/unit. Subcontracting is permissible only after all overtime has been utilized in the particular month, and cannot exceed 50 units in any one month. Shortages (Lost Sales) are permitted, but cost $45/unit short. Backorders are not permitted. Use this production plan: September 80 units/day November 100 units/day October 110 units/day December 80 units/day Additional Assumptions; 200 units of inventory are brought over from the previous August the production rate in August was 100 units/day 1-month subcontracting lead time is required no subcontracting was done in the previous August units produced or subcontracted in a given month and sold in the same month, do not incur an inventory charge all transactions take place at the end of the month Normal regular time, maximum plant capacity is 100 units per working day. Regular time production cost is $20/unit. An additional 10% of capacity can be obtained through overtime, but at an additional cost of $10/unit. Inventory holding cost is $5/unit/month. Changes in the production rate cost $100 per 10 unit change in the rate. Additional capacity may be obtained through sub-contracting at an extra cost of $15/unit. Subcontracting is permissible only after all overtime has been utilized in the particular month, and cannot exceed 50 units in any one month. Shortages (Lost Sales) are permitted, but cost $45/unit short. Backorders are not permitted. Use this production plan: September 80 units/day November 100 units/day October 110 units/day December 80 units/day Additional Assumptions; 200 units of inventory are brought over from the previous August the production rate in August was 100 units/day 1-month subcontracting lead time is required no subcontracting was done in the previous August units produced or subcontracted in a given month and sold in the same month, do not incur an inventory charge all transactions take place at the end of the month