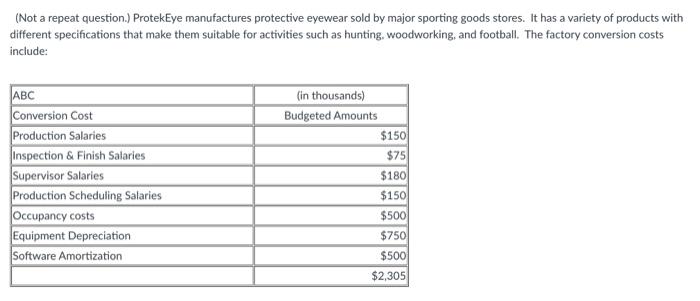

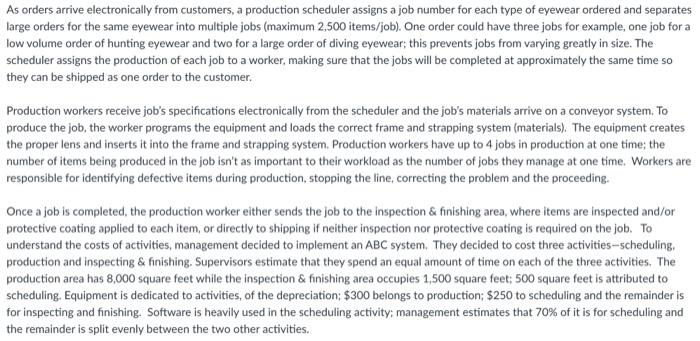

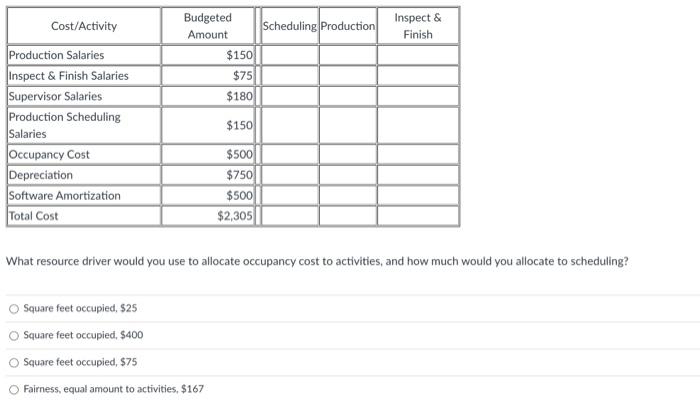

(Not a repeat question.) ProtekEye manufactures protective eyewear sold by major sporting goods stores. It has a variety of products with different specifications that make them suitable for activities such as hunting, woodworking, and football. The factory conversion costs include: As orders arrive electronically from customers, a production scheduler assigns a job number for each type of eyewear ordered and separates large orders for the same eyewear into multiple jobs (maximum 2,500 items/job). One order could have three jobs for example, one job for a low volume order of hunting eyewear and two for a large order of diving eyewear; this prevents jobs from varying greatly in size. The scheduler assigns the production of each job to a worker, making sure that the jobs will be completed at approximately the same time so they can be shipped as one order to the customer. Production workers receive job's specifications electronically from the scheduler and the job's materials arrive on a conveyor system. To produce the job, the worker programs the equipment and loads the correct frame and strapping system (materials). The equipment creates the proper lens and inserts it into the frame and strapping system. Production workers have up to 4 jobs in production at one time; the number of items being produced in the job isn't as important to their workload as the number of jobs they manage at one time. Workers are responsible for identifying defective items during production, stopping the line, correcting the problem and the proceeding. Once a job is completed, the production worker either sends the job to the inspection \& finishing area, where items are inspected and/or protective coating applied to each item, or directly to shipping if neither inspection nor protective coating is required on the job. To understand the costs of activities, management decided to implement an ABC system. They decided to cost three activities-scheduling, production and inspecting \& finishing. Supervisors estimate that they spend an equal amount of time on each of the three activities, The production area has 8,000 square feet while the inspection \& finishing area occupies 1,500 square feet; 500 square feet is attributed to scheduling. Equipment is dedicated to activities, of the depreciation; $300 belongs to production; $250 to scheduling and the remainder is for inspecting and finishing. Software is heavily used in the scheduling activity; management estimates that 70% of it is for scheduling and the remainder is split evenly between the two other activities. What resource driver would you use to allocate occupancy cost to activities, and how much would you allocate to scheduling? Square feet occupied, $25 Square feet occupied, $400 Square feet occupied, $75 Fairness, equal amount to activities, $167