Answered step by step

Verified Expert Solution

Question

1 Approved Answer

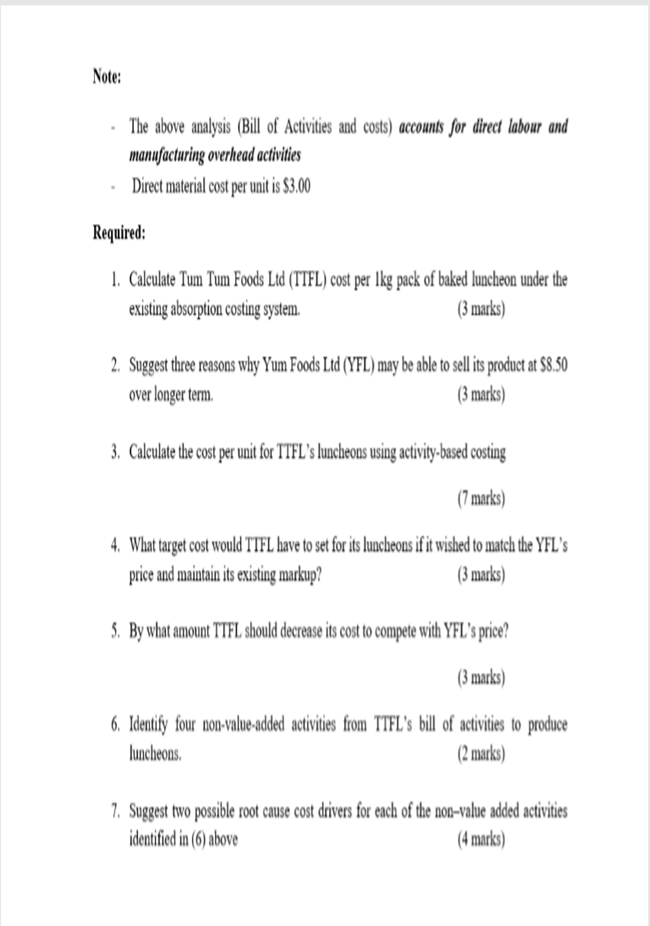

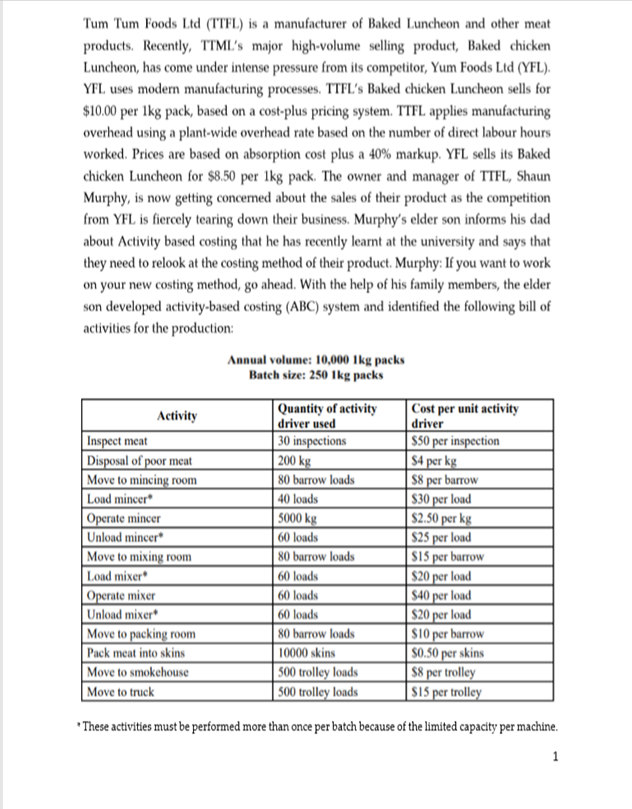

Note: The above analysis (Bill of Activities and costs) accounts for direct labour and manufacturing overhead activities Direct material cost per unit is $3.00

Note: The above analysis (Bill of Activities and costs) accounts for direct labour and manufacturing overhead activities Direct material cost per unit is $3.00 Required: 1. Calculate Tum Tum Foods Ltd (TTFL) cost per 1kg pack of baked luncheon under the existing absorption costing system. (3 marks) 2. Suggest three reasons why Yum Foods Ltd (YFL) may be able to sell its product at $8.50 over longer term. (3 marks) 3. Calculate the cost per unit for TTFL's luncheons using activity-based costing (7 marks) 4. What target cost would TTFL have to set for its luncheons if it wished to match the YFL's price and maintain its existing markup? (3 marks) 5. By what amount TTFL should decrease its cost to compete with YFL's price? (3 marks) 6. Identify four non-value-added activities from TTFL's bill of activities to produce luncheons. (2 marks) 7. Suggest two possible root cause cost drivers for each of the non-value added activities identified in (6) above (4 marks) Tum Tum Foods Ltd (TTFL) is a manufacturer of Baked Luncheon and other meat products. Recently, TTML's major high-volume selling product, Baked chicken Luncheon, has come under intense pressure from its competitor, Yum Foods Ltd (YFL). YFL. uses modern manufacturing processes. TTFL's Baked chicken Luncheon sells for $10.00 per 1kg pack, based on a cost-plus pricing system. TTFL applies manufacturing overhead using a plant-wide overhead rate based on the number of direct labour hours worked. Prices are based on absorption cost plus a 40% markup. YFL sells its Baked chicken Luncheon for $8.50 per 1kg pack. The owner and manager of TTFL, Shaun Murphy, is now getting concerned about the sales of their product as the competition from YFL is fiercely tearing down their business. Murphy's elder son informs his dad about Activity based costing that he has recently learnt at the university and says that they need to relook at the costing method of their product. Murphy: If you want to work on your new costing method, go ahead. With the help of his family members, the elder son developed activity-based costing (ABC) system and identified the following bill of activities for the production: Activity Annual volume: 10,000 1kg packs Batch size: 250 1kg packs Quantity of activity driver used Cost per unit activity driver Inspect meat Disposal of poor meat Move to mincing room Load mincer Operate mincer Unload mincer Move to mixing room Load mixer Operate mixer Unload mixer Move to packing room 30 inspections 200 kg $50 per inspection $4 per kg 80 barrow loads $8 per barrow 40 loads 5000 kg 60 loads 80 barrow loads 60 loads 60 loads 60 loads $30 per load $2.50 per kg $25 per load $15 per barrow $20 per load $40 per load $20 per load $10 per barrow Pack meat into skins Move to smokehouse Move to truck 80 barrow loads 10000 skins $0.50 per skins 500 trolley loads $8 per trolley 500 trolley loads $15 per trolley *These activities must be performed more than once per batch because of the limited capacity per machine. 1

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started