Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Odis Mullenax is the owner and president of Mullenax Automobile Parts Inc. His company makes various parts for major automobile manufacturers worldwide. They manufacture intake

Odis Mullenax is the owner and president of Mullenax Automobile Parts Inc. His company makes various parts for major automobile manufacturers worldwide. They manufacture intake manifold systems, air induction systems, coolant pump modules, oil filtration systems, coil springs, stabilizer bars, precision springs, and other key components within their three business units. Mullenax Automobile Parts Inc. is one link in a very long supply chain. Odis understands that the supply chain isn't a single line of supplier and purchaser. Odis knows that the supply chain is more like a complex web where inputs come from multiple directions, often appearing unrelated to one another.

The automobile industry is extremely competitive no matter where along the supply chain a company is positioned. Therefore, any production slow down, any late delivery, or any quality issues at any point in the supply chain can potentially cause severe problems for those downstream. The consequences for Mullenax Automobile Parts, if they are viewed as the bottleneck, could be a loss of their contract with the major automobile manufacturers.

However, the ramifications can go in both directions. If a major automobile manufacturer shuts down production because another supplier is late delivering a part, such as a semiconductor, Mullenax cannot ship their parts to that manufacturer. Why? Because their agreement is designed around justintime JIT supplier support. If the major manufacturer's production line is shut down for any reason, they cannot use Mullenax's parts. This is a current issue and has required Mullenax to hold over $ million in excess inventory. The implications of supply chain problems go even deeper. No matter where along the supply chain a production line is shut down because of missing parts, workers at the shutdown production line don't get paid.

For Mullenax Automobile Parts and its suppliers and customers, the supply chain is similar to the human circulatory system. A blockage or other potential issue can have serious outcomes throughout the supply chain. For example, the price of lumber has risen and now the price of wooden pallets has almost doubled, from $ to $ When a firm uses over wooden pallets each year like Mullenax, this affects shipping costs. In addition, if they have a late shipment because of a supplier's late delivery, Mullenax must rush the shipment. The additional cost incurred in an expedited shipment comes out of Mullenax's budgetan expense that reduces profit.

Odis sees all the operations issues his company must deal with and develops a plan to address them all. His first target is demand management. Since many of the parts made by Mullenax are used by all major automobile manufacturers, sound demand management could be the key to avoiding problems, such as the current $ million in excess inventory. For many of the products they manufacture, if one customer shuts down because of a problem unrelated to Mullenax, they may be able to adjust their production by shifting some of the product to another major automobile manufacturer.

Odis tasks Estella Epperson, vice president of operations, to examine their demand forecasting system. The goal is to ensure it is flexible enough to deal with significant disruptions caused by upstream issues. Odis wants to avoid $ million in excess inventory in the future.

Estella begins a conversation with Deon Durr, vice president of Marketing. Marketing drives sales; thus, it is the source for customer demand, essential information for demand forecasting. As part of their initiative to improve demand forecasting, they had already moved to cloudbased forecasting solutions. The use of cloudbased forecasting will enable Mullenax Automobile Parts Inc. and its suppliers and customers to provide critical information that will enable Mullenax to know in real time any changes to the flow of parts and materials throughout its extended supply chain.

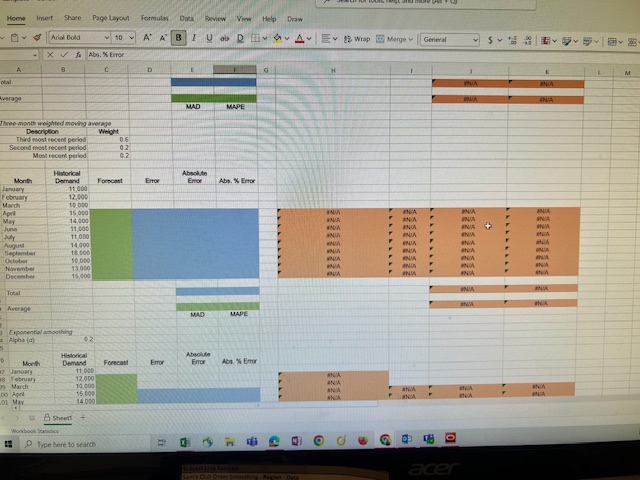

However, Estella and Deon realize that technology is not always reliable. Although they have tremendous confidence in the cloudbased system, if the system should crash for even a day their ability to meet any changes in demand will be compromised. Consequently, they decided to have a backup system using Excel. Clearly, a manual process it is not ideal, but necessary, just in case. As part of their backup plan, the Excel demand forecasting templates will have three demand forecasting methods available: two and threemonth moving averages, a weighted threemonth moving average, and exponential smoothing. This will allow Mullenax and its partners to determine which method will provide the most accurate forecast for the specific situation if the backup system must be utilized.

To test this backup system, they use the following historical data from a cloudbased system.

Jan Feb Mar Apr May Jun Jul Aug Sept Oct Nov Dec

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started