Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Olsen Ropes, a Norwegian Company, produces ropes exclusively for the maritime industry since 1777. Through a standardized product range Olsen Ropes can cover all

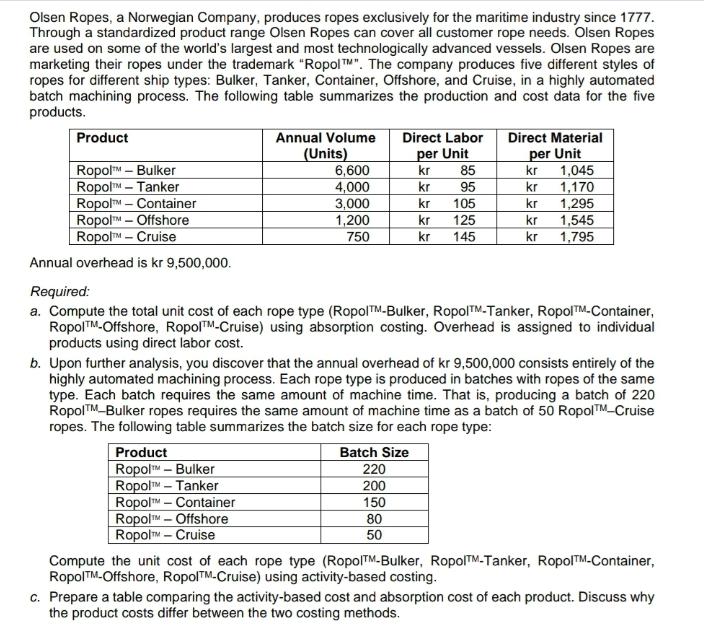

Olsen Ropes, a Norwegian Company, produces ropes exclusively for the maritime industry since 1777. Through a standardized product range Olsen Ropes can cover all customer rope needs. Olsen Ropes are used on some of the world's largest and most technologically advanced vessels. Olsen Ropes are marketing their ropes under the trademark "Ropol TM". The company produces five different styles of ropes for different ship types: Bulker, Tanker, Container, Offshore, and Cruise, in a highly automated batch machining process. The following table summarizes the production and cost data for the five products. Product RopolM- Bulker Ropol - Tanker RopolM-Container RopolM Offshore Ropol - Cruise Annual overhead is kr 9,500,000. Annual Volume (Units) 6,600 4,000 3,000 1,200 750 Product Ropol - Bulker Tanker Ropol Direct Labor per Unit kr Ropol-Container RopolTM-Offshore Ropol-Cruise kr kr 85 95 105 Required: a. Compute the total unit cost of each rope type (RopolTM-Bulker, RopolTM-Tanker, Ropol-Container, RopolM-Offshore, RopolTM-Cruise) using absorption costing. Overhead is assigned to individual products using direct labor cost. Batch Size 220 200 150 80 50 kr 125 kr 145 b. Upon further analysis, you discover that the annual overhead of kr 9,500,000 consists entirely of the highly automated machining process. Each rope type is produced in batches with ropes of the same type. Each batch requires the same amount of machine time. That is, producing a batch of 220 RopolM-Bulker ropes requires the same amount of machine time as a batch of 50 RopolM_Cruise ropes. The following table summarizes the batch size for each rope type: Direct Material per Unit kr 1,045 kr 1,170 kr 1,295 kr 1,545 kr 1,795 Compute the unit cost of each rope type (RopolTM-Bulker, RopolTM-Tanker, RopolM-Container, RopolTM-Offshore, RopolTM-Cruise) using activity-based costing. c. Prepare a table comparing the activity-based cost and absorption cost of each product. Discuss why the product costs differ between the two costing methods.

Step by Step Solution

★★★★★

3.40 Rating (156 Votes )

There are 3 Steps involved in it

Step: 1

a Absorption Costing To calculate the total unit cost of each rope type using absorption costing we need to allocate the overhead based on direct labo...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started