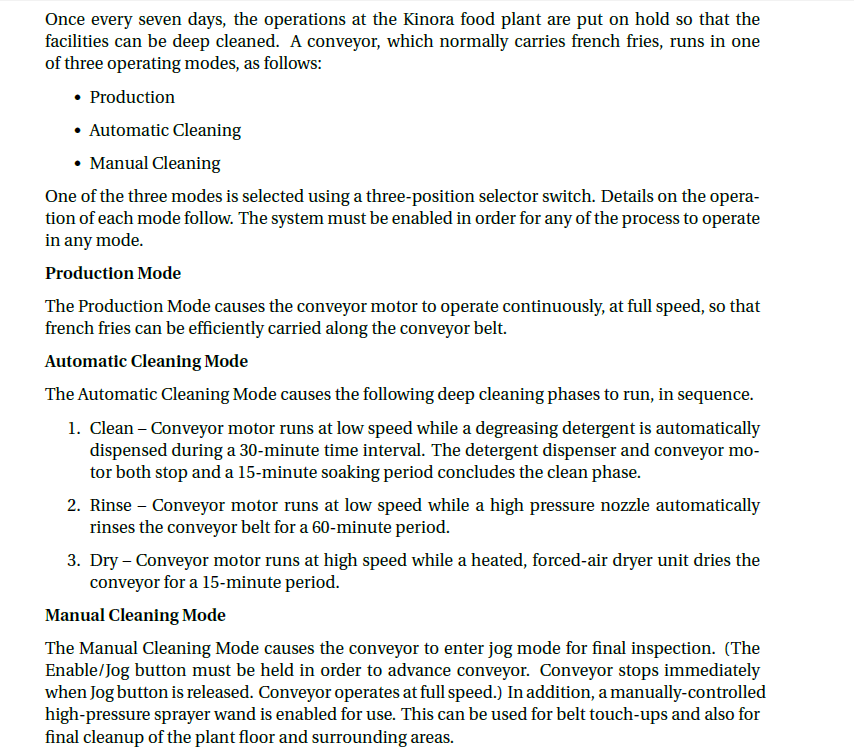

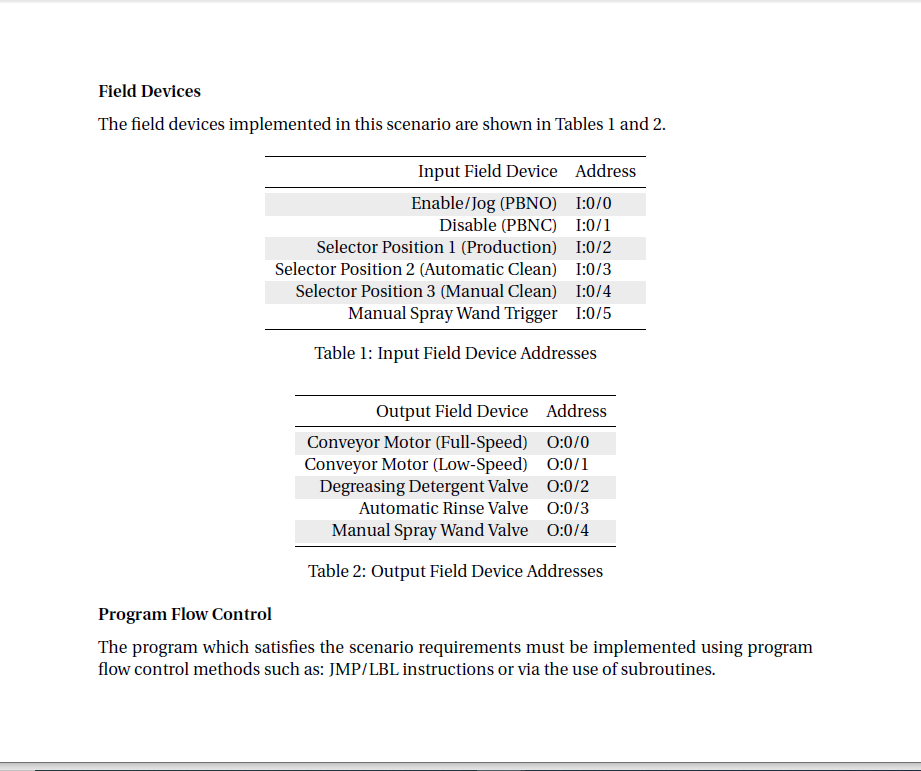

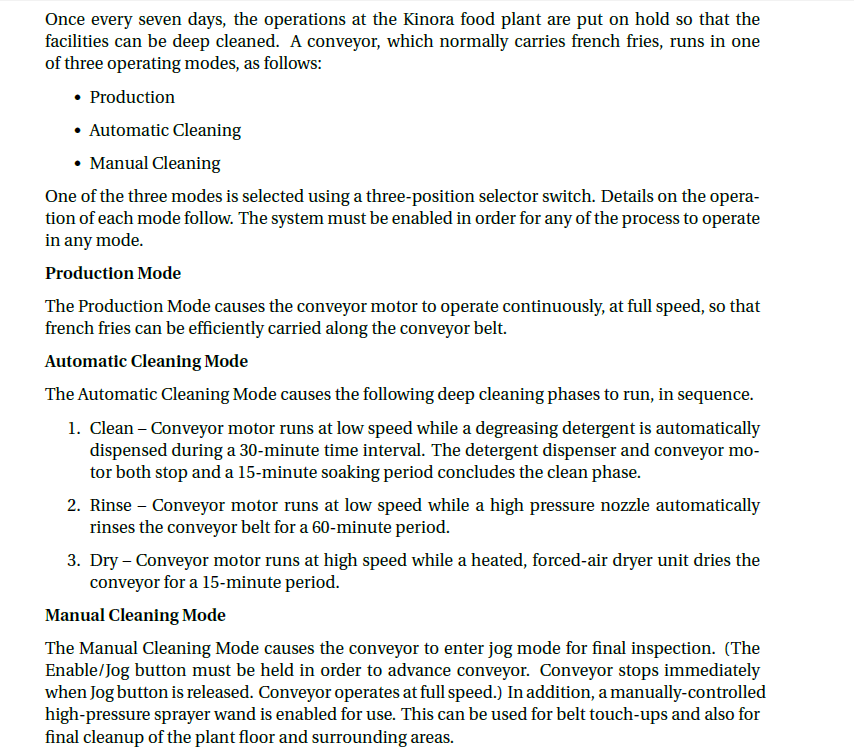

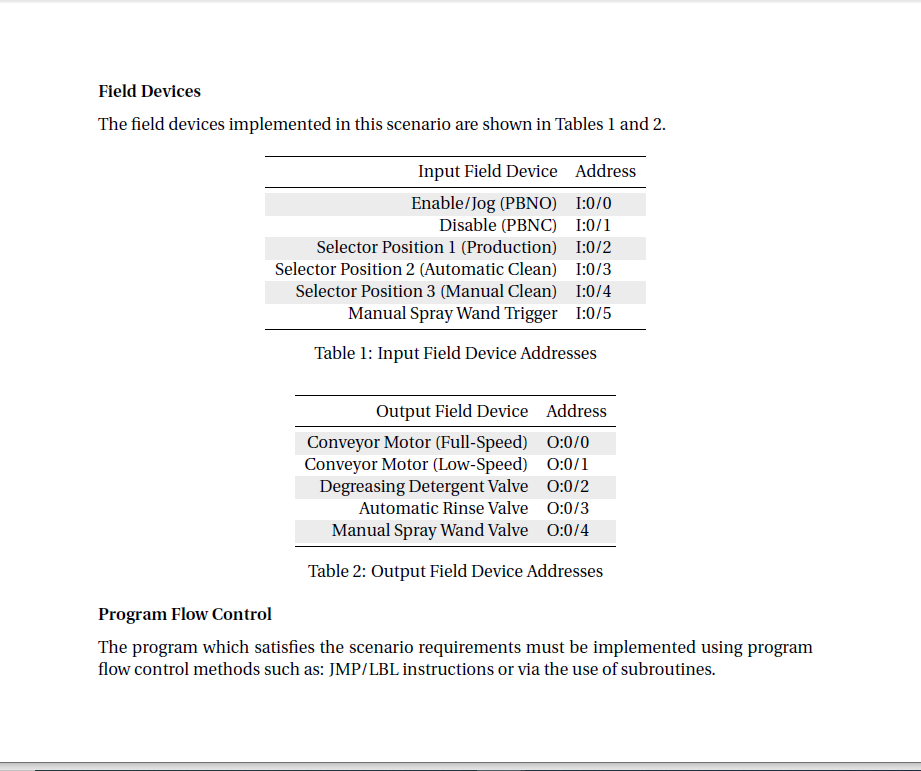

Once every seven days, the operations at the Kinora food plant are put on hold so that the facilities can be deep cleaned. A conveyor, which normally carries french fries, runs in one of three operating modes, as follows: Production Automatic Cleaning Manual Cleaning One of the three modes is selected using a three-position selector switch. Details on the opera- tion of each mode follow. The system must be enabled in order for any of the process to operate in any mode. Production Mode The Production Mode causes the conveyor motor to operate continuously, at full speed, so that french fries can be efficiently carried along the conveyor belt. Automatic Cleaning Mode The Automatic Cleaning Mode causes the following deep cleaning phases to run, in sequence. 1. Clean - Conveyor motor runs at low speed while a degreasing detergent is automatically dispensed during a 30-minute time interval. The detergent dispenser and conveyor mo- tor both stop and a 15-minute soaking period concludes the clean phase. 2. Rinse - Conveyor motor runs at low speed while a high pressure nozzle automatically rinses the conveyor belt for a 60-minute period. 3. Dry - Conveyor motor runs at high speed while a heated, forced-air dryer unit dries the conveyor for a 15-minute period. Manual Cleaning Mode The Manual Cleaning Mode causes the conveyor to enter jog mode for final inspection. (The Enable/Jog button must be held in order to advance conveyor. Conveyor stops immediately when Jog button is released. Conveyor operates at full speed.) In addition, a manually-controlled high-pressure sprayer wand is enabled for use. This can be used for belt touch-ups and also for final cleanup of the plant floor and surrounding areas. Field Devices The field devices implemented in this scenario are shown in Tables 1 and 2. Input Field Device Address Enable/Jog (PBNO) 1:0/0 Disable (PBNC) 1:0/1 Selector Position 1 (Production) 1:0/2 Selector Position 2 (Automatic Clean) 1:0/3 Selector Position 3 (Manual Clean) 1:0/4 Manual Spray Wand Trigger 1:0/5 Table 1: Input Field Device Addresses Output Field Device Address Conveyor Motor (Full-Speed) 0:0/0 Conveyor Motor (Low-Speed) 0:0/1 Degreasing Detergent Valve 0:0/2 Automatic Rinse Valve 0:0/3 Manual Spray Wand Valve 0:0/4 Table 2: Output Field Device Addresses Program Flow Control The program which satisfies the scenario requirements must be implemented using program flow control methods such as: JMP/LBL instructions or via the use of subroutines. Once every seven days, the operations at the Kinora food plant are put on hold so that the facilities can be deep cleaned. A conveyor, which normally carries french fries, runs in one of three operating modes, as follows: Production Automatic Cleaning Manual Cleaning One of the three modes is selected using a three-position selector switch. Details on the opera- tion of each mode follow. The system must be enabled in order for any of the process to operate in any mode. Production Mode The Production Mode causes the conveyor motor to operate continuously, at full speed, so that french fries can be efficiently carried along the conveyor belt. Automatic Cleaning Mode The Automatic Cleaning Mode causes the following deep cleaning phases to run, in sequence. 1. Clean - Conveyor motor runs at low speed while a degreasing detergent is automatically dispensed during a 30-minute time interval. The detergent dispenser and conveyor mo- tor both stop and a 15-minute soaking period concludes the clean phase. 2. Rinse - Conveyor motor runs at low speed while a high pressure nozzle automatically rinses the conveyor belt for a 60-minute period. 3. Dry - Conveyor motor runs at high speed while a heated, forced-air dryer unit dries the conveyor for a 15-minute period. Manual Cleaning Mode The Manual Cleaning Mode causes the conveyor to enter jog mode for final inspection. (The Enable/Jog button must be held in order to advance conveyor. Conveyor stops immediately when Jog button is released. Conveyor operates at full speed.) In addition, a manually-controlled high-pressure sprayer wand is enabled for use. This can be used for belt touch-ups and also for final cleanup of the plant floor and surrounding areas. Field Devices The field devices implemented in this scenario are shown in Tables 1 and 2. Input Field Device Address Enable/Jog (PBNO) 1:0/0 Disable (PBNC) 1:0/1 Selector Position 1 (Production) 1:0/2 Selector Position 2 (Automatic Clean) 1:0/3 Selector Position 3 (Manual Clean) 1:0/4 Manual Spray Wand Trigger 1:0/5 Table 1: Input Field Device Addresses Output Field Device Address Conveyor Motor (Full-Speed) 0:0/0 Conveyor Motor (Low-Speed) 0:0/1 Degreasing Detergent Valve 0:0/2 Automatic Rinse Valve 0:0/3 Manual Spray Wand Valve 0:0/4 Table 2: Output Field Device Addresses Program Flow Control The program which satisfies the scenario requirements must be implemented using program flow control methods such as: JMP/LBL instructions or via the use of subroutines