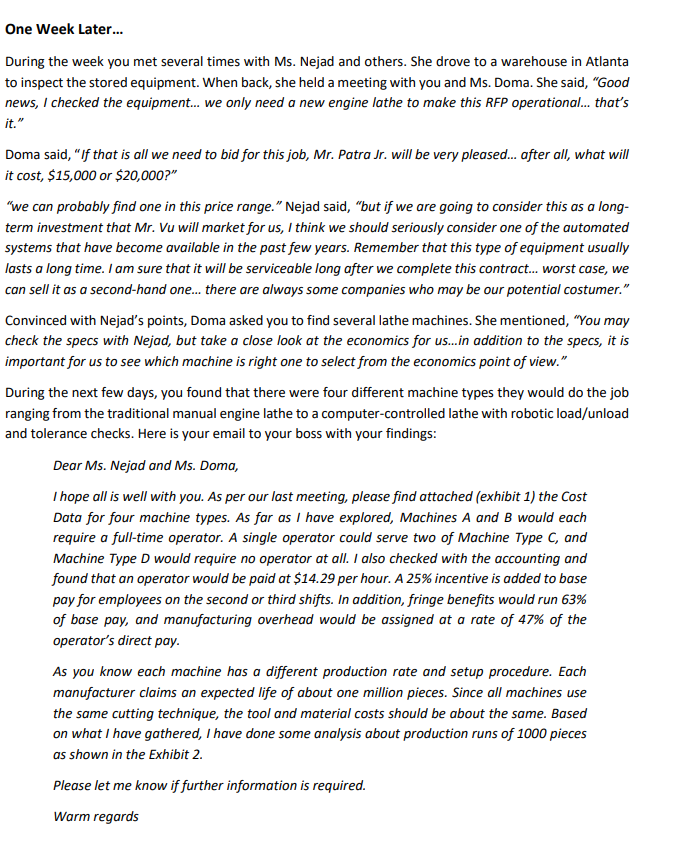

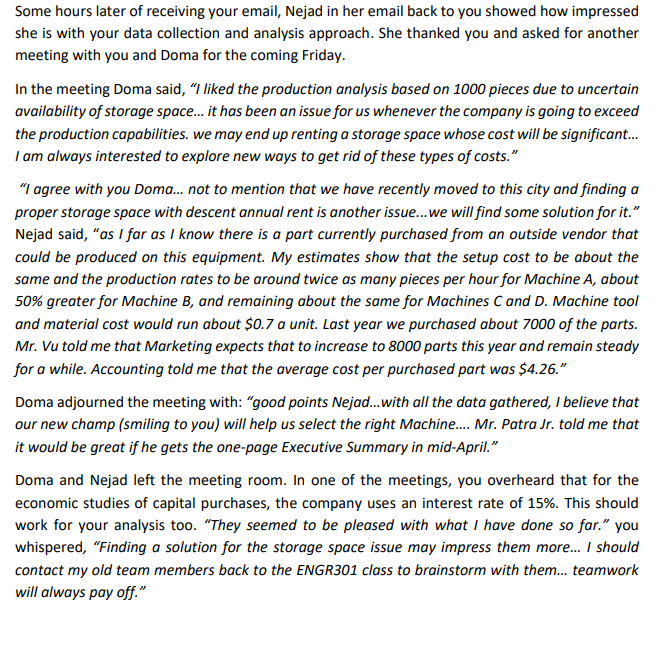

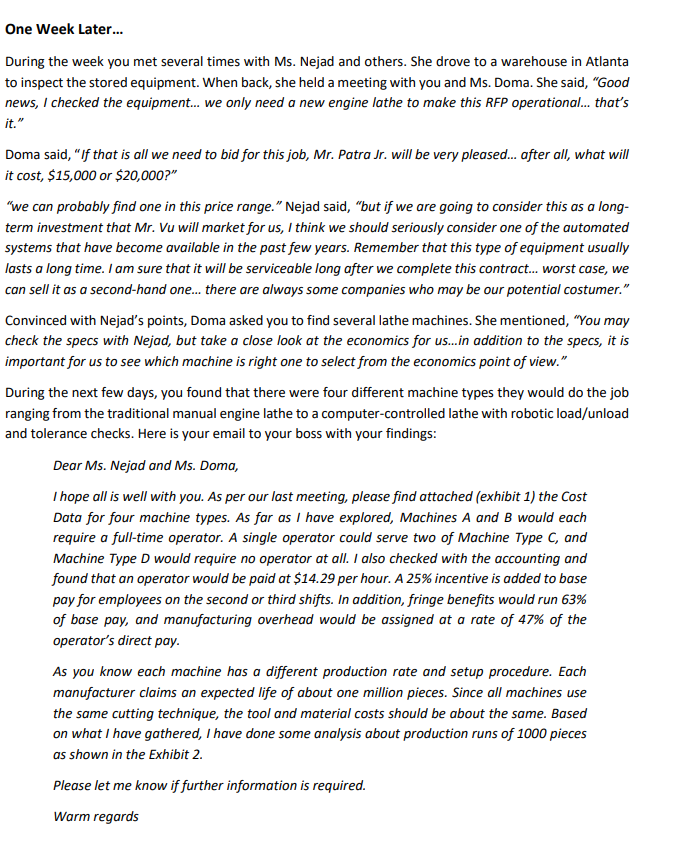

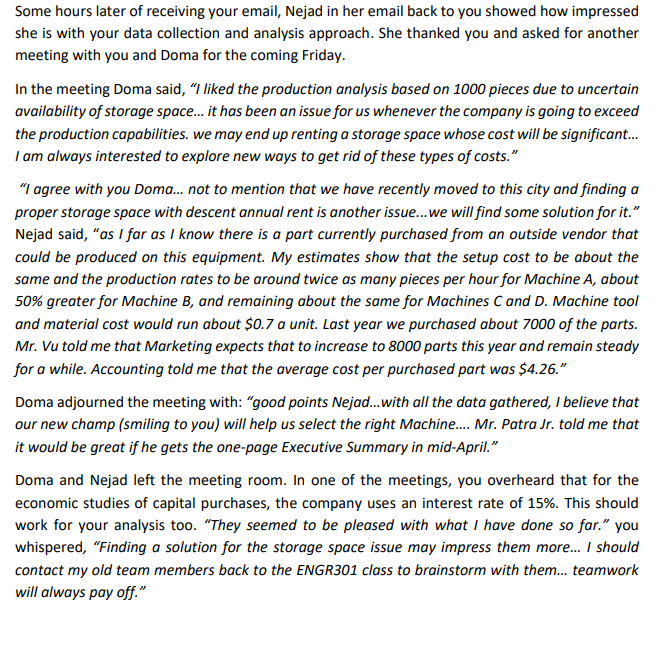

One Week Later... During the week you met several times with Ms. Nejad and others. She drove to a warehouse in Atlanta to inspect the stored equipment. When back, she held a meeting with you and Ms. Doma. She said, "Good news, I checked the equipment... we only need a new engine lathe to make this RFP operational... that's it." Doma said, "If that is all we need to bid for this job, Mr. Patra Jr. will be very pleased... after all, what will it cost, $15,000 or $20,000?" "we can probably find one in this price range." Nejad said, "but if we are going to consider this as a long- term investment that Mr. Vu will market for us, I think we should seriously consider one of the automated systems that have become available in the past few years. Remember that this type of equipment usually lasts a long time. I am sure that it will be serviceable long after we complete this contract... Worst case, we can sell it as a second-hand one... there are always some companies who may be our potential costumer." Convinced with Nejad's points, Doma asked you to find several lathe machines. She mentioned, "You may check the specs with Nejad, but take a close look at the economics for us...in addition to the specs, it is important for us to see which machine is right one to select from the economics point of view." During the next few days, you found that there were four different machine types they would do the job ranging from the traditional manual engine lathe to a computer-controlled lathe with robotic load/unload and tolerance checks. Here is your email to your boss with your findings: Dear Ms. Nejad and Ms. Doma, I hope all is well with you. As per our last meeting, please find attached (exhibit 1) the Cost Data for four machine types. As far as I have explored, Machines A and B would each require a full-time operator. A single operator could serve two of Machine Type C, and Machine Type D would require no operator at all. I also checked with the accounting and found that an operator would be paid at $14.29 per hour. A 25% incentive is added to base pay for employees on the second or third shifts. In addition, fringe benefits would run 63% of base pay, and manufacturing overhead would be assigned at a rate of 47% of the operator's direct pay. As you know each machine has a different production rate and setup procedure. Each manufacturer claims an expected life of about one million pieces. Since all machines use the same cutting technique, the tool and material costs should be about the same. Based on what I have gathered, I have done some analysis about production runs of 1000 pieces as shown in the Exhibit 2. Please let me know if further information is required. Warm regards Some hours later of receiving your email, Nejad in her email back to you showed how impressed she is with your data collection and analysis approach. She thanked you and asked for another meeting with you and Doma for the coming Friday. In the meeting Doma said, I liked the production analysis based on 1000 pieces due to uncertain availability of storage space... it has been an issue for us whenever the company is going to exceed the production capabilities. we may end up renting a storage space whose cost will be significant... I am always interested to explore new ways to get rid of these types of costs." "I agree with you Doma... not to mention that we have recently moved to this city and finding a proper storage space with descent annual rent is another issue...we will find some solution for it. Nejad said, " as I far as I know there is a part currently purchased from an outside vendor that could be produced on this equipment. My estimates show that the setup cost to be about the same and the production rates to be around twice as many pieces per hour for Machine A, about 50% greater for Machine B, and remaining about the same for Machines C and D. Machine tool and material cost would run about $0.7 a unit. Last year we purchased about 7000 of the parts. Mr. Vu told me that Marketing expects that to increase to 8000 parts this year and remain steady for a while. Accounting told me that the average cost per purchased part was $4.26." Doma adjourned the meeting with: "good points Nejad...with all the data gathered, I believe that our new champ (smiling to you) will help us select the right Machine.... Mr. Patra Jr. told me that it would be great if he gets the one-page Executive Summary in mid-April." Doma and Nejad left the meeting room. In one of the meetings, you overheard that for the economic studies of capital purchases, the company uses an interest rate of 15%. This should work for your analysis too. They seemed to be pleased with what I have done so far." you whispered, Finding a solution for the storage space issue may impress them more... I should contact my old team members back to the ENGR301 class to brainstorm with them... teamwork will always pay off." Exhibit 1: Cost Data for four machine types Machine Type A. Manual B. Semiautomatic C. Automatic D. Automatic with Robotic load/unload Cost Data Purchase Cost $18,000 $27,000 $64,000 $124,000 Annual Maintenance Cost $1,350 $2,430 $4,250 $14,400 Exhibit 2: Production Data for four machine types Machine A B Setup Cost $750 $1000 $3000 $6000 Production Data Production Rate (Pieces/hr.) 6 pieces 12 pieces 30 pieces 30 pieces Material + Tool (Cost/piece) $0.50 $0.50 $0.50 $0.50 D One Week Later... During the week you met several times with Ms. Nejad and others. She drove to a warehouse in Atlanta to inspect the stored equipment. When back, she held a meeting with you and Ms. Doma. She said, "Good news, I checked the equipment... we only need a new engine lathe to make this RFP operational... that's it." Doma said, "If that is all we need to bid for this job, Mr. Patra Jr. will be very pleased... after all, what will it cost, $15,000 or $20,000?" "we can probably find one in this price range." Nejad said, "but if we are going to consider this as a long- term investment that Mr. Vu will market for us, I think we should seriously consider one of the automated systems that have become available in the past few years. Remember that this type of equipment usually lasts a long time. I am sure that it will be serviceable long after we complete this contract... Worst case, we can sell it as a second-hand one... there are always some companies who may be our potential costumer." Convinced with Nejad's points, Doma asked you to find several lathe machines. She mentioned, "You may check the specs with Nejad, but take a close look at the economics for us...in addition to the specs, it is important for us to see which machine is right one to select from the economics point of view." During the next few days, you found that there were four different machine types they would do the job ranging from the traditional manual engine lathe to a computer-controlled lathe with robotic load/unload and tolerance checks. Here is your email to your boss with your findings: Dear Ms. Nejad and Ms. Doma, I hope all is well with you. As per our last meeting, please find attached (exhibit 1) the Cost Data for four machine types. As far as I have explored, Machines A and B would each require a full-time operator. A single operator could serve two of Machine Type C, and Machine Type D would require no operator at all. I also checked with the accounting and found that an operator would be paid at $14.29 per hour. A 25% incentive is added to base pay for employees on the second or third shifts. In addition, fringe benefits would run 63% of base pay, and manufacturing overhead would be assigned at a rate of 47% of the operator's direct pay. As you know each machine has a different production rate and setup procedure. Each manufacturer claims an expected life of about one million pieces. Since all machines use the same cutting technique, the tool and material costs should be about the same. Based on what I have gathered, I have done some analysis about production runs of 1000 pieces as shown in the Exhibit 2. Please let me know if further information is required. Warm regards Some hours later of receiving your email, Nejad in her email back to you showed how impressed she is with your data collection and analysis approach. She thanked you and asked for another meeting with you and Doma for the coming Friday. In the meeting Doma said, I liked the production analysis based on 1000 pieces due to uncertain availability of storage space... it has been an issue for us whenever the company is going to exceed the production capabilities. we may end up renting a storage space whose cost will be significant... I am always interested to explore new ways to get rid of these types of costs." "I agree with you Doma... not to mention that we have recently moved to this city and finding a proper storage space with descent annual rent is another issue...we will find some solution for it. Nejad said, " as I far as I know there is a part currently purchased from an outside vendor that could be produced on this equipment. My estimates show that the setup cost to be about the same and the production rates to be around twice as many pieces per hour for Machine A, about 50% greater for Machine B, and remaining about the same for Machines C and D. Machine tool and material cost would run about $0.7 a unit. Last year we purchased about 7000 of the parts. Mr. Vu told me that Marketing expects that to increase to 8000 parts this year and remain steady for a while. Accounting told me that the average cost per purchased part was $4.26." Doma adjourned the meeting with: "good points Nejad...with all the data gathered, I believe that our new champ (smiling to you) will help us select the right Machine.... Mr. Patra Jr. told me that it would be great if he gets the one-page Executive Summary in mid-April." Doma and Nejad left the meeting room. In one of the meetings, you overheard that for the economic studies of capital purchases, the company uses an interest rate of 15%. This should work for your analysis too. They seemed to be pleased with what I have done so far." you whispered, Finding a solution for the storage space issue may impress them more... I should contact my old team members back to the ENGR301 class to brainstorm with them... teamwork will always pay off." Exhibit 1: Cost Data for four machine types Machine Type A. Manual B. Semiautomatic C. Automatic D. Automatic with Robotic load/unload Cost Data Purchase Cost $18,000 $27,000 $64,000 $124,000 Annual Maintenance Cost $1,350 $2,430 $4,250 $14,400 Exhibit 2: Production Data for four machine types Machine A B Setup Cost $750 $1000 $3000 $6000 Production Data Production Rate (Pieces/hr.) 6 pieces 12 pieces 30 pieces 30 pieces Material + Tool (Cost/piece) $0.50 $0.50 $0.50 $0.50 D