ONLY 5-B ANSWER ?

ONLY 5-B ANSWER ?

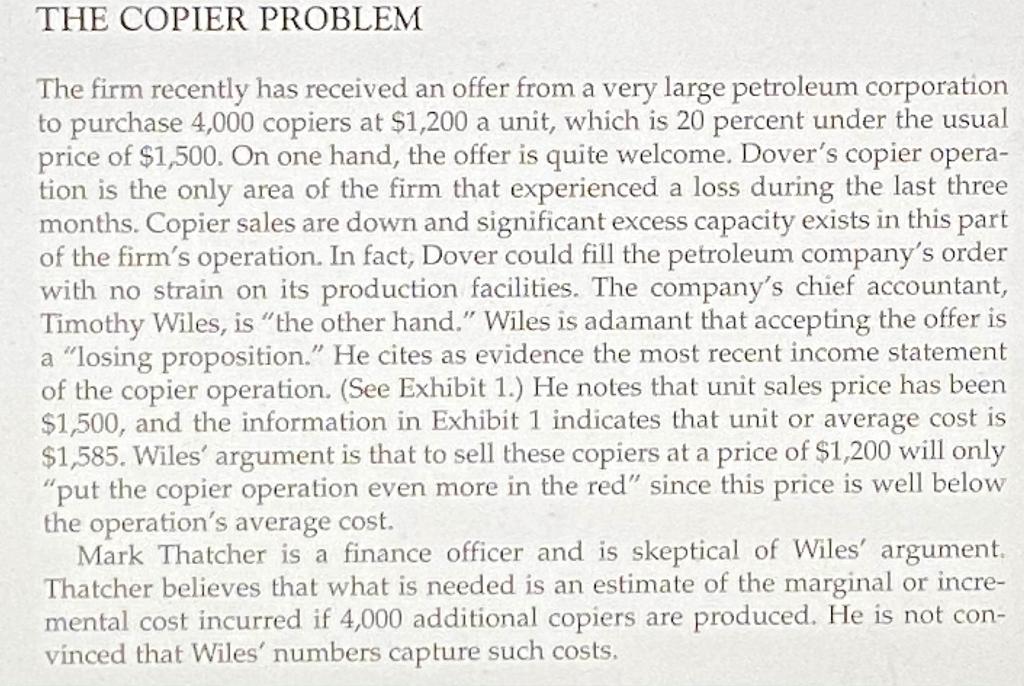

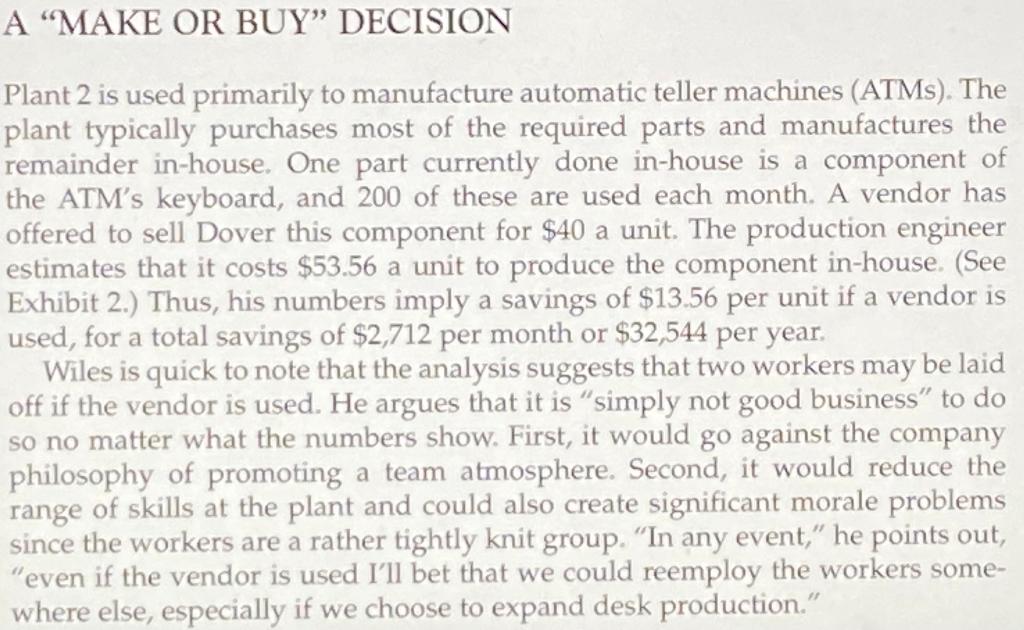

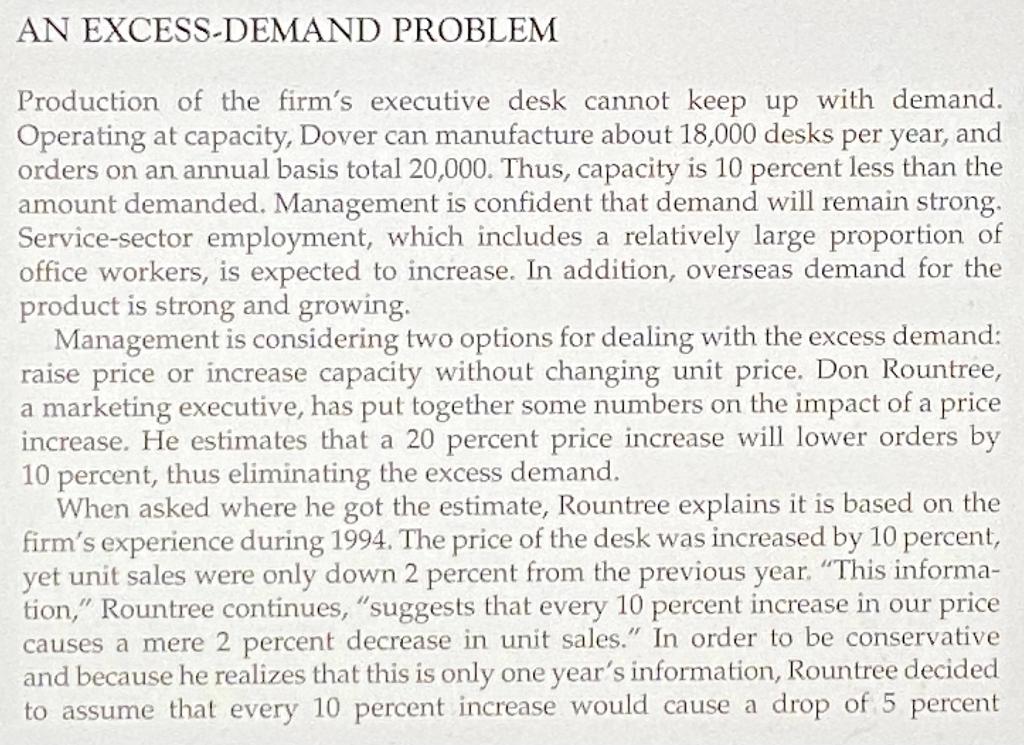

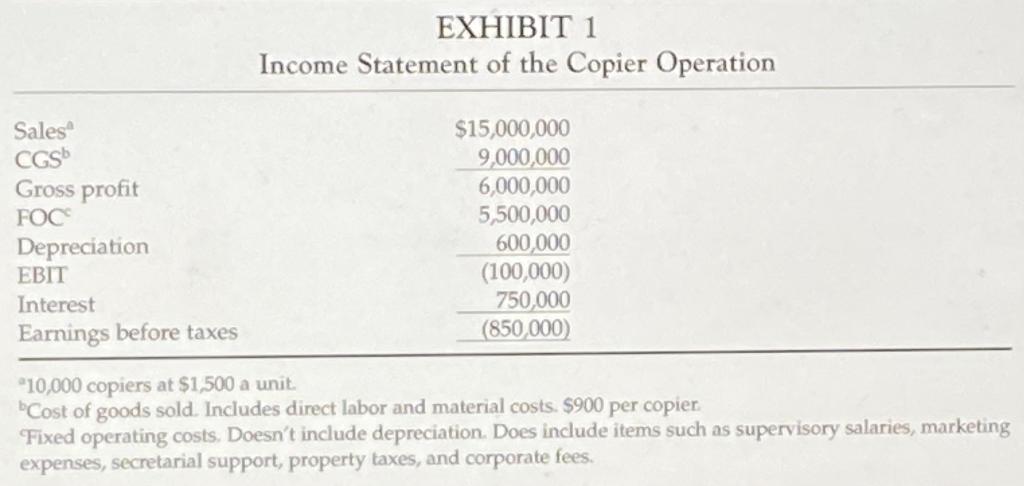

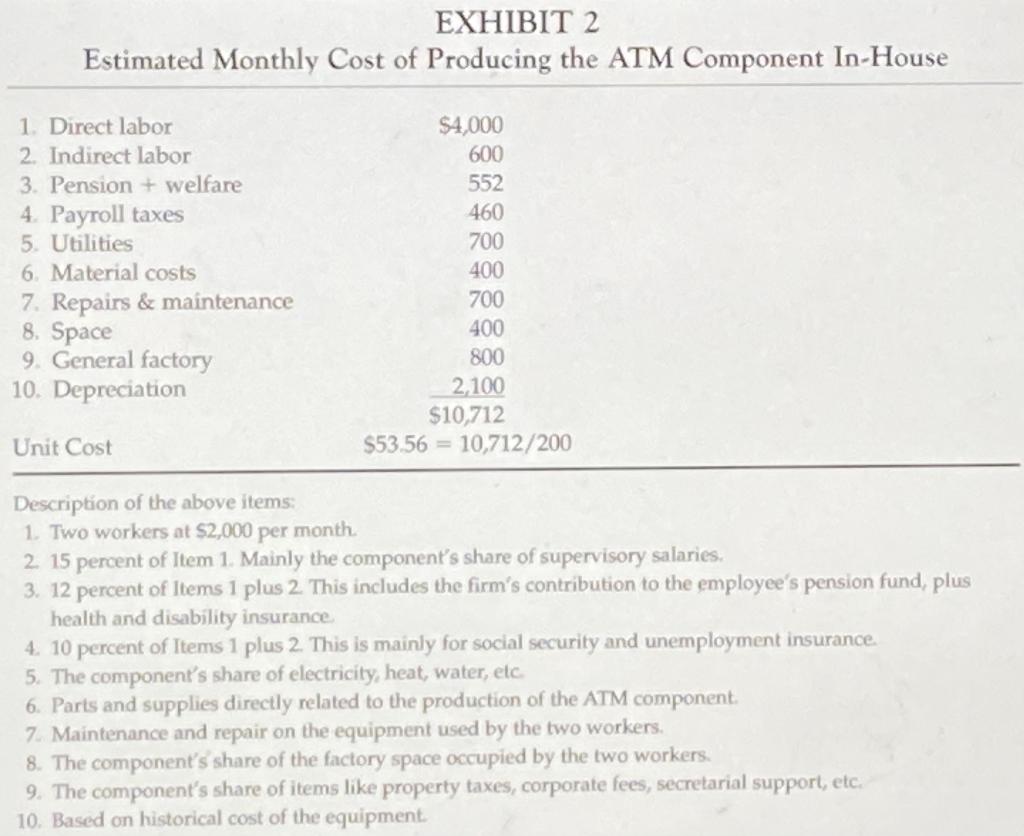

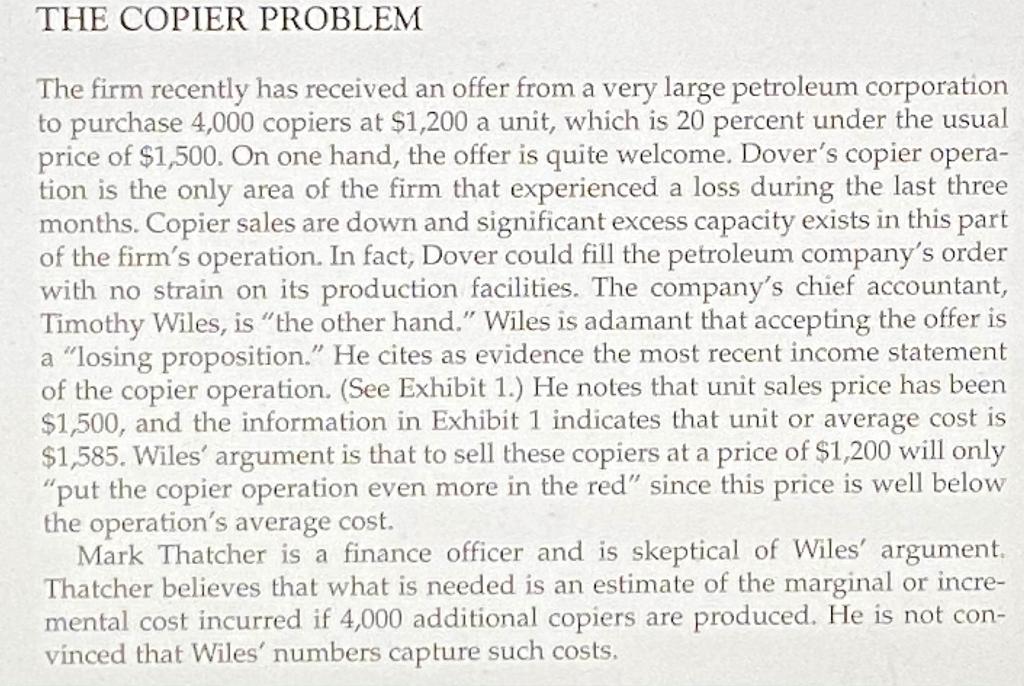

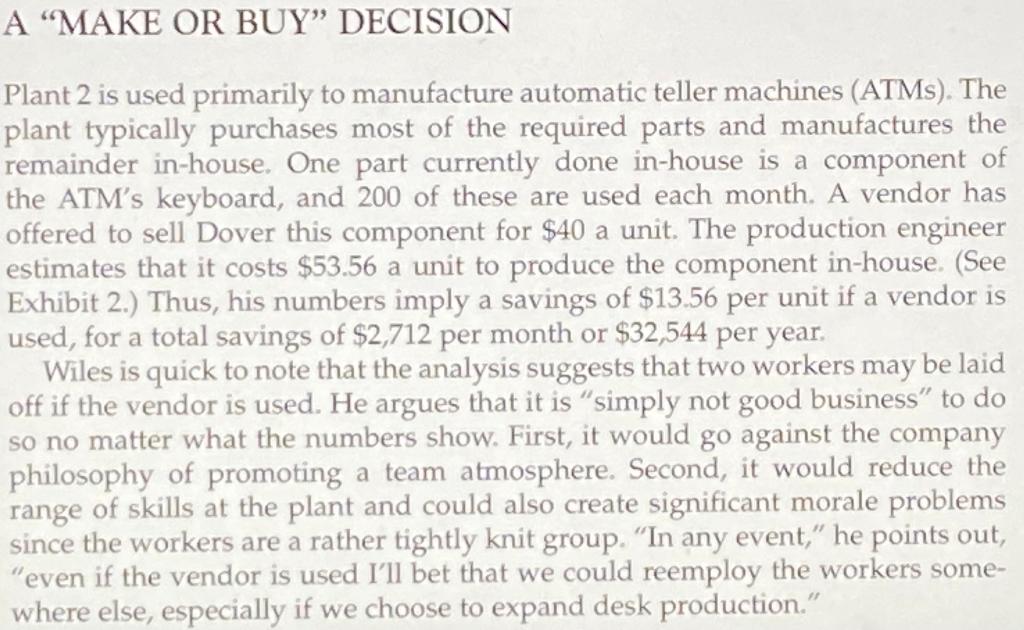

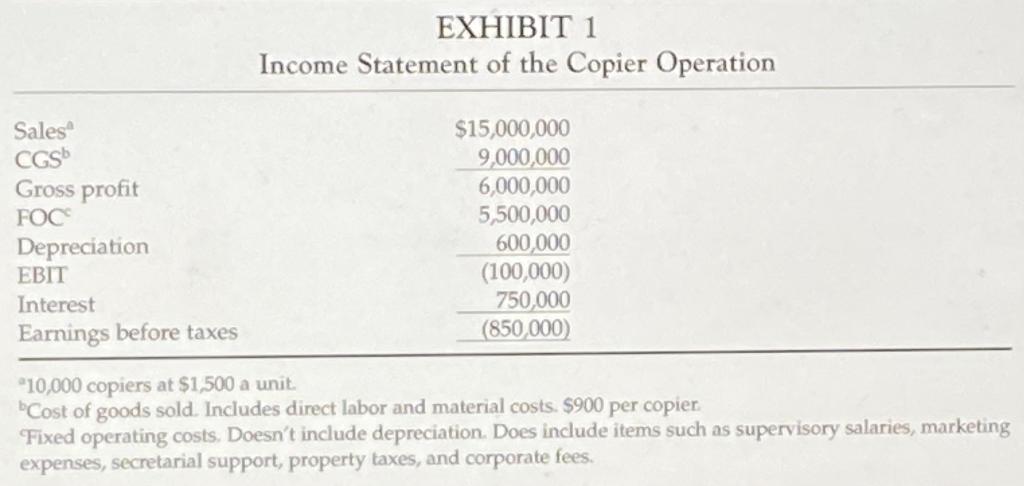

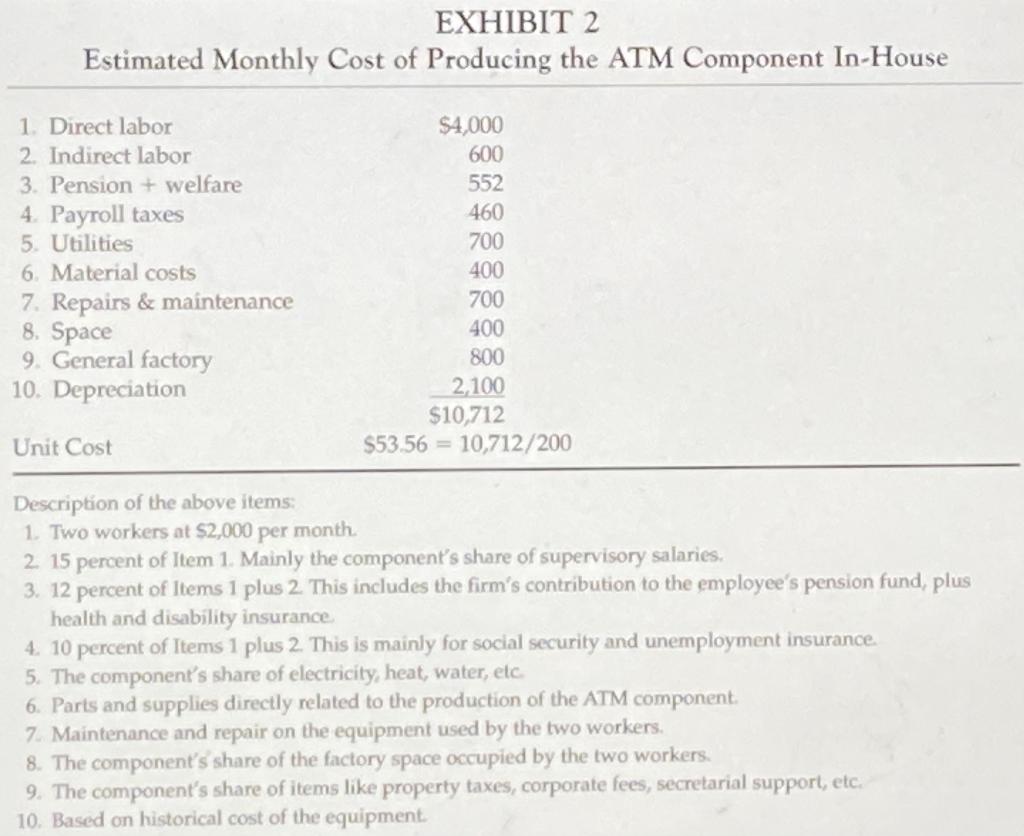

THE COPIER PROBLEM The firm recently has received an offer from a very large petroleum corporation to purchase 4,000 copiers at $1,200 a unit, which is 20 percent under the usual price of $1,500. On one hand, the offer is quite welcome. Dover's copier opera- tion is the only area of the firm that experienced a loss during the last three months. Copier sales are down and significant excess capacity exists in this part of the firm's operation. In fact, Dover could fill the petroleum company's order with no strain on its production facilities. The company's chief accountant, Timothy Wiles, is "the other hand." Wiles is adamant that accepting the offer is a "losing proposition. He cites as evidence the most recent income statement of the copier operation. (See Exhibit 1.) He notes that unit sales price has been $1,500, and the information in Exhibit 1 indicates that unit or average cost is $1,585. Wiles' argument is that to sell these copiers at a price of $1,200 will only "put the copier operation even more in the red" since this price is well below the operation's average cost. Mark Thatcher is a finance officer and is skeptical of Wiles' argument Thatcher believes that what is needed is an estimate of the marginal or incre- mental cost incurred if 4,000 additional copiers are produced. He is not con- vinced that Wiles' numbers capture such costs. A "MAKE OR BUY DECISION Plant 2 is used primarily to manufacture automatic teller machines (ATMs). The plant typically purchases most of the required parts and manufactures the remainder in-house. One part currently done in-house is a component of the ATM's keyboard, and 200 of these are used each month. A vendor has offered to sell Dover this component for $40 a unit. The production engineer estimates that it costs $53.56 a unit to produce the component in-house. (See Exhibit 2.) Thus, his numbers imply a savings of $13.56 per unit if a vendor is used, for a total savings of $2,712 per month or $32,544 per year. Wiles is quick to note that the analysis suggests that two workers may be laid off if the vendor is used. He argues that it is "simply not good business to do so no matter what the numbers show. First, it would go against the company philosophy of promoting a team atmosphere. Second, it would reduce the range of skills at the plant and could also create significant morale problems since the workers are a rather tightly knit group. "In any event," he points out, "even if the vendor is used I'll bet that we could reemploy the workers some- where else, especially if we choose to expand desk production." AN EXCESS-DEMAND PROBLEM Production of the firm's executive desk cannot keep up with demand. Operating at capacity, Dover can manufacture about 18,000 desks per year, and orders on an annual basis total 20,000. Thus, capacity is 10 percent less than the amount demanded. Management is confident that demand will remain strong. Service-sector employment, which includes a relatively large proportion of office workers, is expected to increase. In addition, overseas demand for the product is strong and growing. Management is considering two options for dealing with the excess demand: raise price or increase capacity without changing unit price. Don Rountree, a marketing executive, has put together some numbers on the impact of a price increase. He estimates that a 20 percent price increase will lower orders by 10 percent, thus eliminating the excess demand. When asked where he got the estimate, Rountree explains it is based on the firm's experience during 1994. The price of the desk was increased by 10 percent, yet unit sales were only down 2 percent from the previous year. "This informa- 2 tion," Rountree continues, "suggests that every 10 percent increase in our price causes a mere 2 percent decrease in unit sales." In order to be conservative and because he realizes that this is only one year's information, Rountree decided to assume that every 10 percent increase would cause a drop of 5 percent in unit sales. This estimate, therefore, indicates that a 20 percent price increase will lower the amount demanded by 10 percent; that is, the yearly quantity demanded is predicted to drop from 20,000 to 18,000. Margaret Williamson, one of the firm's economists, is skeptical of this evidence and thinks that the drop in unit sales will be "much more" than these numbers suggest. She points out that customers are quite price conscious and that reasonable substitutes for the desk are made by other firms. She also notes that 1994 was a very strong year for the economy and especially the office furniture industry. "Plus," she continues, "in 1994 nearly all competitors raised prices because of substantially higher material costs. What we're analyzing here is a price hike while our competitors keep theirs constant." Thatcher agrees with Williamson and thinks that it makes more sense to expand capacity. He has worked up a set of numbers on such an expansion assuming a 10-year time period, the firm's typical planning horizon for a proj- ect of this type. Thatcher claims that the present value of the yearly cash flows is $14 million, or nearly 100 percent more than the up-front cost of $7.6 million. These numbers, therefore, suggests that Dover would make a rather large economic profit from an expansion. Williamson finds these numbers "interesting" but questions Thatcher's unit sales projections. Thatcher defends these forecasts by noting that he's assuming no changes in unit price or existing demand. "There's no pie-in-the-sky here," he claims. "Marketing feels that the demand increase for the desks is quite permanent. And, besides, all the information we have indicates that our competitors are operating at or near capacity also." EXHIBIT 1 Income Statement of the Copier Operation Sales $15,000,000 CGS 9,000,000 Gross profit 6,000,000 FOCe 5,500,000 Depreciation 600,000 EBIT (100,000) Interest 750,000 Earnings before taxes (850,000) *10,000 copiers at $1,500 a unit. Cost of goods sold. Includes direct labor and material costs. $900 per copier Fixed operating costs. Doesn't include depreciation. Does include items such as supervisory salaries, marketing expenses, secretarial support, property taxes, and corporate fees. EXHIBIT 2 Estimated Monthly Cost of Producing the ATM Component In-House 1. Direct labor 2. Indirect labor 3. Pension + welfare 4. Payroll taxes 5. Utilities 6. Material costs 7. Repairs & maintenance 8. Space 9. General factory 10. Depreciation $4,000 600 552 460 700 400 700 400 800 2.100 $10,712 $5356 = 10,712/200 Unit Cost Description of the above items 1. Two workers at $2,000 per month 2. 15 percent of Item 1. Mainly the component's share of supervisory salaries. 3. 12 percent of Items 1 plus 2. This includes the firm's contribution to the employee's pension fund, plus health and disability insurance 4. 10 percent of Items 1 plus 2. This is mainly for social security and unemployment insurance. 5. The component's share of electricity, heat, water, etc 6. Parts and supplies directly related to the production of the ATM component 7. Maintenance and repair on the equipment used by the two workers. 8. The component's share of the factory space occupied by the two workers. 9. The component's share of items like property taxes, corporate fees, secretarial support, etc. 10. Based on historical cost of the equipment 5. (a) What are economic profits? (b) Under what circumstances, if any, can a firm expect to make economic profits? 6. The firm's economist is quite skeptical of the cost/revenue estimates associ TAThere THE COPIER PROBLEM The firm recently has received an offer from a very large petroleum corporation to purchase 4,000 copiers at $1,200 a unit, which is 20 percent under the usual price of $1,500. On one hand, the offer is quite welcome. Dover's copier opera- tion is the only area of the firm that experienced a loss during the last three months. Copier sales are down and significant excess capacity exists in this part of the firm's operation. In fact, Dover could fill the petroleum company's order with no strain on its production facilities. The company's chief accountant, Timothy Wiles, is "the other hand." Wiles is adamant that accepting the offer is a "losing proposition. He cites as evidence the most recent income statement of the copier operation. (See Exhibit 1.) He notes that unit sales price has been $1,500, and the information in Exhibit 1 indicates that unit or average cost is $1,585. Wiles' argument is that to sell these copiers at a price of $1,200 will only "put the copier operation even more in the red" since this price is well below the operation's average cost. Mark Thatcher is a finance officer and is skeptical of Wiles' argument Thatcher believes that what is needed is an estimate of the marginal or incre- mental cost incurred if 4,000 additional copiers are produced. He is not con- vinced that Wiles' numbers capture such costs. A "MAKE OR BUY DECISION Plant 2 is used primarily to manufacture automatic teller machines (ATMs). The plant typically purchases most of the required parts and manufactures the remainder in-house. One part currently done in-house is a component of the ATM's keyboard, and 200 of these are used each month. A vendor has offered to sell Dover this component for $40 a unit. The production engineer estimates that it costs $53.56 a unit to produce the component in-house. (See Exhibit 2.) Thus, his numbers imply a savings of $13.56 per unit if a vendor is used, for a total savings of $2,712 per month or $32,544 per year. Wiles is quick to note that the analysis suggests that two workers may be laid off if the vendor is used. He argues that it is "simply not good business to do so no matter what the numbers show. First, it would go against the company philosophy of promoting a team atmosphere. Second, it would reduce the range of skills at the plant and could also create significant morale problems since the workers are a rather tightly knit group. "In any event," he points out, "even if the vendor is used I'll bet that we could reemploy the workers some- where else, especially if we choose to expand desk production." AN EXCESS-DEMAND PROBLEM Production of the firm's executive desk cannot keep up with demand. Operating at capacity, Dover can manufacture about 18,000 desks per year, and orders on an annual basis total 20,000. Thus, capacity is 10 percent less than the amount demanded. Management is confident that demand will remain strong. Service-sector employment, which includes a relatively large proportion of office workers, is expected to increase. In addition, overseas demand for the product is strong and growing. Management is considering two options for dealing with the excess demand: raise price or increase capacity without changing unit price. Don Rountree, a marketing executive, has put together some numbers on the impact of a price increase. He estimates that a 20 percent price increase will lower orders by 10 percent, thus eliminating the excess demand. When asked where he got the estimate, Rountree explains it is based on the firm's experience during 1994. The price of the desk was increased by 10 percent, yet unit sales were only down 2 percent from the previous year. "This informa- 2 tion," Rountree continues, "suggests that every 10 percent increase in our price causes a mere 2 percent decrease in unit sales." In order to be conservative and because he realizes that this is only one year's information, Rountree decided to assume that every 10 percent increase would cause a drop of 5 percent in unit sales. This estimate, therefore, indicates that a 20 percent price increase will lower the amount demanded by 10 percent; that is, the yearly quantity demanded is predicted to drop from 20,000 to 18,000. Margaret Williamson, one of the firm's economists, is skeptical of this evidence and thinks that the drop in unit sales will be "much more" than these numbers suggest. She points out that customers are quite price conscious and that reasonable substitutes for the desk are made by other firms. She also notes that 1994 was a very strong year for the economy and especially the office furniture industry. "Plus," she continues, "in 1994 nearly all competitors raised prices because of substantially higher material costs. What we're analyzing here is a price hike while our competitors keep theirs constant." Thatcher agrees with Williamson and thinks that it makes more sense to expand capacity. He has worked up a set of numbers on such an expansion assuming a 10-year time period, the firm's typical planning horizon for a proj- ect of this type. Thatcher claims that the present value of the yearly cash flows is $14 million, or nearly 100 percent more than the up-front cost of $7.6 million. These numbers, therefore, suggests that Dover would make a rather large economic profit from an expansion. Williamson finds these numbers "interesting" but questions Thatcher's unit sales projections. Thatcher defends these forecasts by noting that he's assuming no changes in unit price or existing demand. "There's no pie-in-the-sky here," he claims. "Marketing feels that the demand increase for the desks is quite permanent. And, besides, all the information we have indicates that our competitors are operating at or near capacity also." EXHIBIT 1 Income Statement of the Copier Operation Sales $15,000,000 CGS 9,000,000 Gross profit 6,000,000 FOCe 5,500,000 Depreciation 600,000 EBIT (100,000) Interest 750,000 Earnings before taxes (850,000) *10,000 copiers at $1,500 a unit. Cost of goods sold. Includes direct labor and material costs. $900 per copier Fixed operating costs. Doesn't include depreciation. Does include items such as supervisory salaries, marketing expenses, secretarial support, property taxes, and corporate fees. EXHIBIT 2 Estimated Monthly Cost of Producing the ATM Component In-House 1. Direct labor 2. Indirect labor 3. Pension + welfare 4. Payroll taxes 5. Utilities 6. Material costs 7. Repairs & maintenance 8. Space 9. General factory 10. Depreciation $4,000 600 552 460 700 400 700 400 800 2.100 $10,712 $5356 = 10,712/200 Unit Cost Description of the above items 1. Two workers at $2,000 per month 2. 15 percent of Item 1. Mainly the component's share of supervisory salaries. 3. 12 percent of Items 1 plus 2. This includes the firm's contribution to the employee's pension fund, plus health and disability insurance 4. 10 percent of Items 1 plus 2. This is mainly for social security and unemployment insurance. 5. The component's share of electricity, heat, water, etc 6. Parts and supplies directly related to the production of the ATM component 7. Maintenance and repair on the equipment used by the two workers. 8. The component's share of the factory space occupied by the two workers. 9. The component's share of items like property taxes, corporate fees, secretarial support, etc. 10. Based on historical cost of the equipment 5. (a) What are economic profits? (b) Under what circumstances, if any, can a firm expect to make economic profits? 6. The firm's economist is quite skeptical of the cost/revenue estimates associ TAThere

ONLY 5-B ANSWER ?

ONLY 5-B ANSWER ?