Question

Our controller, Richard Kimmel is negotiating with potential new Clay suppliers in Kentucky. We need the Large Gnome Divisions Master Budget for the fiscal year

Our controller, Richard Kimmel is negotiating with potential new Clay suppliers in Kentucky. We need the Large Gnome Divisions Master Budget for the fiscal year ended June 30, 2019 for our corporate strategic planning process, and we cannot wait for Richards return from Kentucky. We would like you to prepare the Large Gnome Divisions Master Budget for the fiscal year ended June 30, 2019.

The deliverables are as follows:

8. Cash budget.

9. Budgeted income statement for the year ending June 30, 2019.*

10. Budgeted balance sheet for June 30, 2019.*

All the Master Budget schedules except those marked with an asterisk for the Large Gnome Division should include a column for each quarter and a total column for the fiscal year. We only need annual totals for the budgeted financial statements (schedules 9 and 10) and we only need a year-end total for the value of finished goods inventory (schedule 6).

The hard copies of these budget schedules should be delivered by the company deadline. You can print more than one schedule per page, but do not have a page break in the middle of a budget schedule. I like to be able to view an entire budget schedule without flipping back and forth between pages. Please also use a type font of between 10-12 points for printing. We also need you to submit (via e-mail) the Excel spreadsheet that you used to create the budget schedules you print so we can use the spreadsheet as a starting point for future budgets. Upload the Excel spreadsheet on Blackboard. We need that spreadsheet file the night before the meeting

Ive attached a brief description of the Large Gnome Division to the budget data Richard gave me before he left for Kentucky. We eagerly await your results.

Sincerely, Candice Kimmel

The garden gnomes were first produced in volume made in the German town of Graefenroda by Phillip Griebel back in the mid-1800s. Garden gnomes quickly became popular, and their use as a garden ornament spread from Germany into France and England. With the spreading popularity of garden gnomes, numerous gnome manufacturers sprang up throughout Germany, with each manufacturer developing their own particular style and design.i

Traditional gnomes were made from terracotta clay slurry poured into molds. The gnome is removed from the mold, allowed to dry, and then fired in a kiln until it is hard. Once cooled, the gnome is painted to the level of detail desired.ii German manufacturers disappeared during WWII. Post World War II, gnome production moved to lower cost countries and lower cost processes and materials were used. Most modern gnomes are made from plastic resins using injection molds rather than terracotta.iii Griebel's descendants are the last remaining German producers, and they are last producers making the traditional terracotta garden gnomes.

Kimmel Gnomes, located in South Dakota, may be the only other manufacturer of high quality clay garden gnomes that are hand finished.v Kimmel Gnomes are stoneware, rather than terracotta. Stoneware uses higher-quality clay than terracotta and the gnomes are fired at higher temperature, yielding a stronger, more durable gnome. The gnomes are fired inside and out and are colored with glaze before firing, rather than being painted after firing. As a result Kimmel gnomes retain their color when exposed to the elements and they are not affected by moisture or freezing. The Large Gnome Division manufactures and sells gnomes between 12 and 15 inches in length or height (the Hedgerow Gnome model is shown in the picture to the left). Many different styles are made, but each large gnome requires virtually the same amount of time and materials.

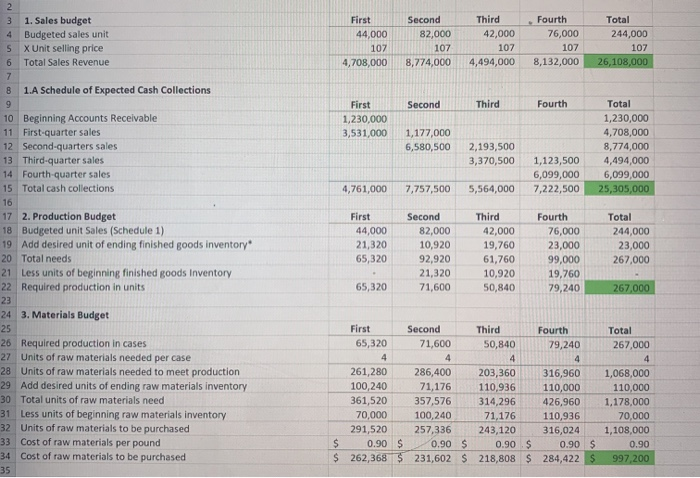

During 2018-19 fiscal year, the average selling price for large gnomes is expected to be $107 per gnome. The Large Gnome Division forecasts the following number gnome sales.

| Quarter | First | Second | Third | Fourth |

| Gnome Sales | 44,000 | 82,000 | 42,000 | 76,000 |

The collection pattern for Accounts Receivable is as follows:

o 75 percent of all sales are collected within the quarter in which they are sold

o 25 percent of all sales are collected in the following quarter.

o There are no bad debts/uncollectables.

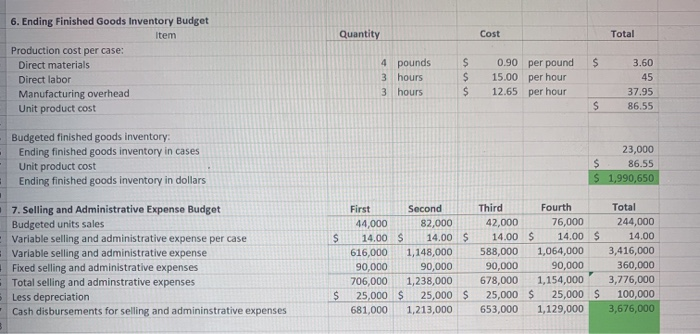

Due to higher than expected demand this year, the Large Gnome Division expects to have no finished gnomes in inventory on July 1, 2018, the beginning of the first quarter of the new fiscal year. To avoid having that problem in the coming fiscal year, the Large Gnome Division would like to have the ending inventory of Gnomes at the end of each of the first three quarters equal to 26% of the budgeted sales for the next quarter. They would like to have 23,000 finished gnomes on hand on June 30, 2019.

| Quarter | First | Secon | Third | Fourth |

| Ending FG inventory in Gnomes as a % of the next quarters budgeted sales | 26% | 26% | 26% | ? |

| Ending FG inventory in Gnomes | ? | ? | ? | 23,000 |

Each large gnome requires an average of 4 pounds of clay. The Large Gnome Division buys clay for $0.90 per pound and they expect the price to remain constant throughout the year. They expect to have 70,000 pounds of clay on hand as of July 1, 2018, the beginning of the first quarter of the fiscal year. At the end of each of the first three quarters, the Large Gnome Division would like to have their direct materials inventory quantity to equal 35 percent of the amount required for the following quarters planned production. On June 30, 2019, the end of the fiscal year, Large Gnome Division would like to have 110,000 pounds of clay on hand

| Quarter | First | Second | Third | Fourth |

| Ending DM inventory as a % of the next quarters production requirement | 35% | 35% | 35% | ? |

| Ending DM inventory in pounds | ? | ? | ? | 110,000 |

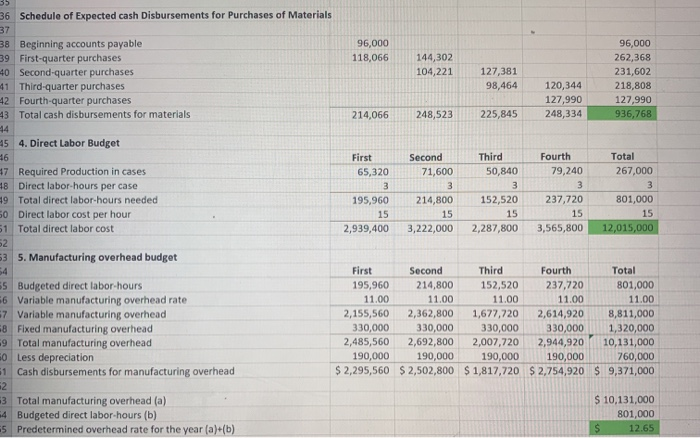

The Large Gnome Division buys its clay on account. It pays for 45% of its purchases of direct materials in the quarter in which they were purchased and 55% in the quarter after they were purchased.

Each large gnome requires 3.00 hours (180 minutes) of direct labor. Employees engaged in direct labor will be paid an estimated $15.00 per labor hour. Wages and salaries are paid on the 15th and 30th of each month.

Variable manufacturing overhead is estimated to be $11.00 per direct labor hour for the coming fiscal year. All variable manufacturing overhead expenses are paid for in the quarter incurred.

Fixed manufacturing overhead is estimated to total $330,000 each quarter, with $190,000 out of the total amount of $330,000 representing depreciation on machinery, equipment and the factory. All other fixed manufacturing overhead expenses are paid in cash in the quarter they occur. The fixed manufacturing overhead rate will be computed by dividing the years total fixed manufacturing overhead by the years budgeted direct labor hours. Round the fixed overhead rate to the nearest penny.

Variable selling and administrative expenses are estimated to be $14.00 per gnome sold. Fixed selling and administrative expenses are expected to total $90,000 each quarter, with $25,000 out of the total amount of $90,000 representing depreciation on the office space, furniture and equipment. Other than depreciation, all selling and administrative expenses are paid for in the quarter they occur.

On June 30, 2019 the Large Gnome Division plans to buy new machinery and equipment for $1,900,000. The new machinery and equipment will be acquired at the very end of the year, so it will not be used in production and sales during the coming year and it will not be depreciated until the following year. The Large Gnome Division expects to pay 15% down and finance the remaining 85% of the equipment cost with a loan. No interest payable will accrue on the equipment loan until after June 30, 2019.

The Division must maintain a minimum cash balance of $60,000. If after accounting for cash receipts and disbursements (including dividends) in the cash budget, the budgeted cash available cash falls below $60,000 in any quarter, the Division will need to borrow cash. They have arranged a line of credit with Liberty Bank, allowing it to borrow in $10,000 increments. Assume borrowing will take place at the beginning of any quarter in which the available cash would otherwise be below $60,000 so that at no time during the quarter will the cash balance fall below $60,000 (after payment of interest). If there is extra cash at the end of the quarter and there is borrowing outstanding, the division should pay down principal (also in increments of $10,000). Liberty Bank charges the Division interest at the rate of 1.0% per quarter, which must be paid at the end of each quarter.

As a fully owned subsidiary, the Large Gnome Division does not pay income taxes. All income taxes are charged to Kimmel Gnomes, the parent company. Large Gnome Division will pay dividends of $25,000each quarter to its corporate parent, Kimmel Gnomes. The dividends must be paid, even if the Large Gnome Division has to borrow on its line of credit to make the payment.

The budgeted balance sheet for the Large Gnome Division on June 30, 2018 (which is the same as the budgeted balance sheet at the beginning of business July 1, 2018) is presented below. Kimmel Gnomes owns 100% of the Capital Stock of the Large Gnome Division.

LARGE GNOME DIVISION KIMMEL GNOMES BUDGETED BALANCE SHEET JUNE 30, 2018

| Assets | LIABILITIES & EQUITY |

| Cash $208,000 | Accounts Payable $96,000 |

| Accounts Receivable 1,230,000 | Notes Payable 0 |

| Raw Material Inventory 63,000 | Capital Stock 4,000,000 |

| Plant and Equipment 14,500,000 | Retained Earnings 11,905,000 |

| TOTAL ASSETS $16,001,000 | TTL LIAB. & SE $16,001,000 |

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started