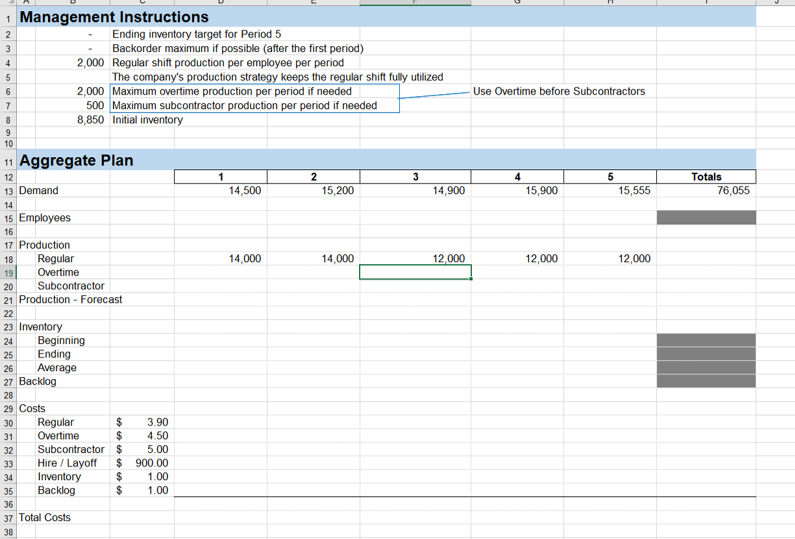

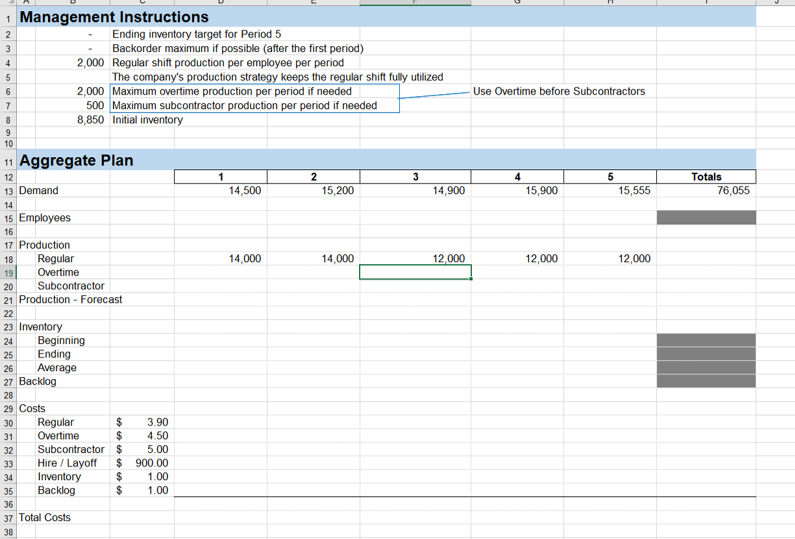

perform the necessary calculations for a Match (Chase) Production Strategy. Then enter selected values below.

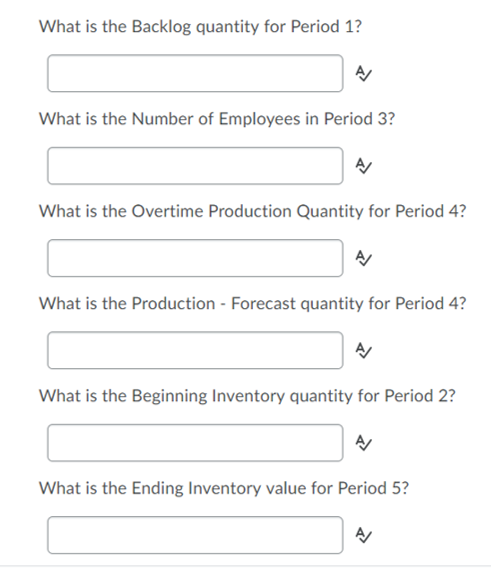

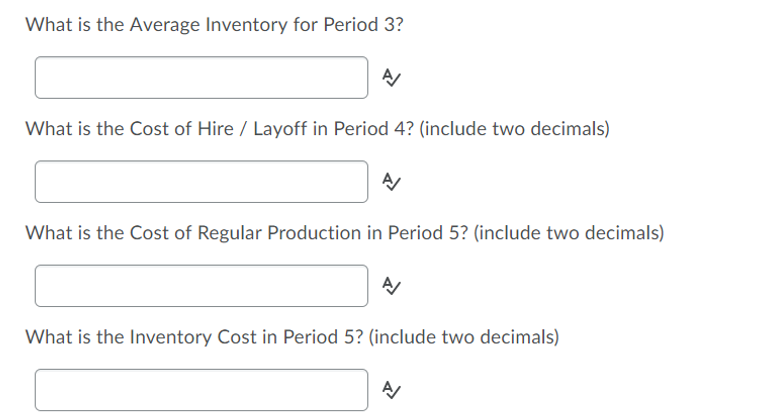

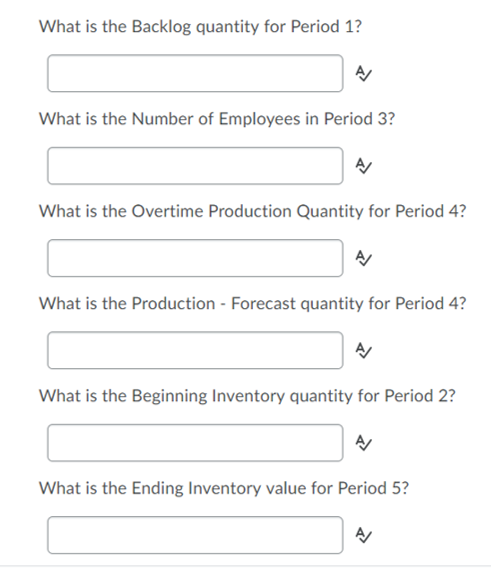

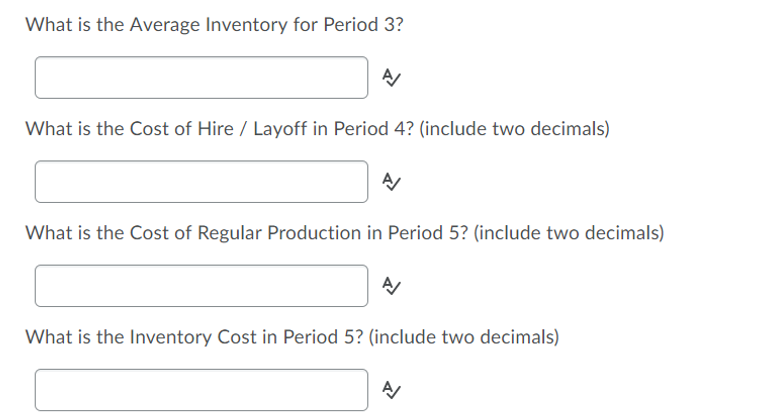

1 Management Instructions Ending inventory target for Period 5 Backorder maximum if possible (after the first period) 2,000 Regular shift production per employee per period The company's production strategy keeps the regular shift fully utilized 2,000 Maximum overtime production per period if needed 500 Maximum subcontractor production per period if needed 8,850 Initial inventory Use Overtime before Subcontractors 11 Aggregate Plan 3 4 5 13 Demand 12 14,500 1 5,200 14,900 15,900 15,555 Totals 7 6,055 15 Employees 16 14,000 14,000 12,000 12,000 12,000 25 17 Production 18 Regular Overtime 20 Subcontractor 21 Production - Forecast 22 23 Inventory 24 Beginning Ending 26 Average 27 Backlog 28 29 Costs 30 Regular $ 31 Overtime $ 32 Subcontractor $ 33 Hire / Layoff $ 34 Inventory $ Backlog $ 3.90 4.50 5.00 900.00 1.00 1.00 35 37 Total Costs 38 What is the Backlog quantity for Period 1? What is the Number of Employees in Period 3? What is the Overtime Production Quantity for Period 4? What is the Production - Forecast quantity for Period 4? What is the Beginning Inventory quantity for Period 2? What is the Ending Inventory value for Period 5? What is the Average Inventory for Period 3? What is the Cost of Hire / Layoff in Period 4? (include two decimals) What is the Cost of Regular Production in Period 5? (include two decimals) What is the Inventory Cost in Period 5? (include two decimals) 1 Management Instructions Ending inventory target for Period 5 Backorder maximum if possible (after the first period) 2,000 Regular shift production per employee per period The company's production strategy keeps the regular shift fully utilized 2,000 Maximum overtime production per period if needed 500 Maximum subcontractor production per period if needed 8,850 Initial inventory Use Overtime before Subcontractors 11 Aggregate Plan 3 4 5 13 Demand 12 14,500 1 5,200 14,900 15,900 15,555 Totals 7 6,055 15 Employees 16 14,000 14,000 12,000 12,000 12,000 25 17 Production 18 Regular Overtime 20 Subcontractor 21 Production - Forecast 22 23 Inventory 24 Beginning Ending 26 Average 27 Backlog 28 29 Costs 30 Regular $ 31 Overtime $ 32 Subcontractor $ 33 Hire / Layoff $ 34 Inventory $ Backlog $ 3.90 4.50 5.00 900.00 1.00 1.00 35 37 Total Costs 38 What is the Backlog quantity for Period 1? What is the Number of Employees in Period 3? What is the Overtime Production Quantity for Period 4? What is the Production - Forecast quantity for Period 4? What is the Beginning Inventory quantity for Period 2? What is the Ending Inventory value for Period 5? What is the Average Inventory for Period 3? What is the Cost of Hire / Layoff in Period 4? (include two decimals) What is the Cost of Regular Production in Period 5? (include two decimals) What is the Inventory Cost in Period 5? (include two decimals)