Question

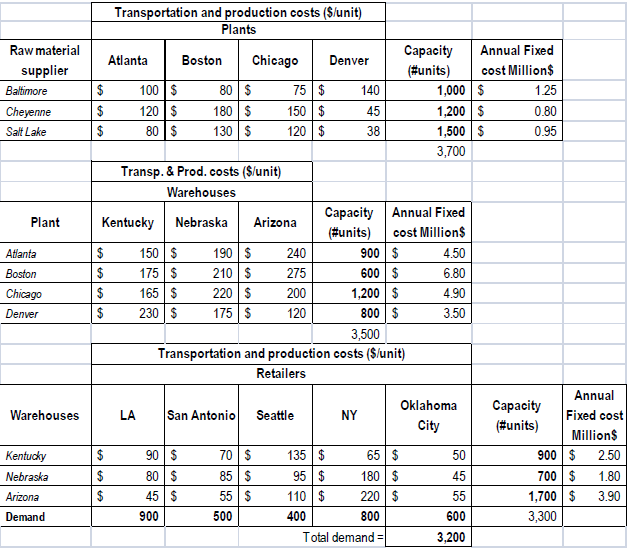

PLANT LOCATION PROBLEM Consider the problem of simultaneous location of facilities in a supply chain studied in class and whose fixed and variable costs are

PLANT LOCATION PROBLEM Consider the problem of simultaneous location of facilities in a supply chain studied in class and whose fixed and variable costs are shown below:

Solve the problem of simultaneous location of facilities by attending to the following specific instructions:

- With the exception of demand points (retailers), it is allowed to close facilities at any level of the supply chain.

- The sales management has agreed that the demand (at the retailer level) will be satisfied to a maximum of 95%.

- The supply chain strategic planning team has determined that no facility (raw material suppliers, production plants, and warehouses) should operate at less than 60% capacity. If required, it is preferred to close operations at said facility.

Important note: Fixed costs can be placed as constant values to the model.

Determine the location of the facilities as well as the quantities that are shipped between levels of the supply chain that minimize total costs and meet established requirements. For the solution use the LINDO software.

Raw material supplier Baltimore Cheyenne Salt Lake Plant Atlanta Boston Chicago Denver Transportation and production costs ($/unit) Plants Capacity Annual Fixed Atlanta Boston Chicago Denver (#units) cost Million $ $ 100$ 80$ 75$ 140 1,000 $ 1.25 $ 120$ 180$ 150 $ 45 1,200 $ 0.80 $ 80$ 130$ 120 $ 38 1,500 $ 0.95 3,700 Transp. & Prod. costs ($/unit) Warehouses Kentucky Nebraska Arizona Capacity Annual Fixed (#units) cost Millions $ 150 $ 190$ 240 900 $ 4.50 $ 175$ 210$ 275 600 $ 6.80 165$ 220$ 200 1,200 $ 4.90 $ 230$ 175$ 120 800$ 3.50 3,500 Transportation and production costs ($/unit) Retailers Annual Oklahoma Capacity San Antonio Seattle NY Fixed cost City #units) Millions $ 90$ 70$ 135$ 65$ 50 900$ 2.50 $ 80$ 85$ 95 $ 180 $ 45 700$ 45$ 55$ 110$ 220$ 55 1,700$ 3.90 900 500 400 800 600 3,300 Total demand = 3,200 $ Warehouses LA 1.80 Kentucky Nebraska Arizona Demand Raw material supplier Baltimore Cheyenne Salt Lake Plant Atlanta Boston Chicago Denver Transportation and production costs ($/unit) Plants Capacity Annual Fixed Atlanta Boston Chicago Denver (#units) cost Million $ $ 100$ 80$ 75$ 140 1,000 $ 1.25 $ 120$ 180$ 150 $ 45 1,200 $ 0.80 $ 80$ 130$ 120 $ 38 1,500 $ 0.95 3,700 Transp. & Prod. costs ($/unit) Warehouses Kentucky Nebraska Arizona Capacity Annual Fixed (#units) cost Millions $ 150 $ 190$ 240 900 $ 4.50 $ 175$ 210$ 275 600 $ 6.80 165$ 220$ 200 1,200 $ 4.90 $ 230$ 175$ 120 800$ 3.50 3,500 Transportation and production costs ($/unit) Retailers Annual Oklahoma Capacity San Antonio Seattle NY Fixed cost City #units) Millions $ 90$ 70$ 135$ 65$ 50 900$ 2.50 $ 80$ 85$ 95 $ 180 $ 45 700$ 45$ 55$ 110$ 220$ 55 1,700$ 3.90 900 500 400 800 600 3,300 Total demand = 3,200 $ Warehouses LA 1.80 Kentucky Nebraska Arizona DemandStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started