Question

Plastic Bottle Inc. (PBI) makes PET (polyethylene terephthalate) bottles. PET bottles are produced using a two-stage reheat and blow process. In the rst stage, amorphous

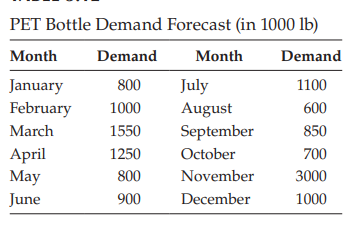

Plastic Bottle Inc. (PBI) makes PET (polyethylene terephthalate) bottles. PET bottles are produced using a two-stage reheat and blow process. In the rst stage, amorphous PET is injection molded into a carefully designed preform, which is compact, rugged, and can be transported economically. In the second stage, the amorphous preform is passed through a multistage infrared oven where it is reheated to approximately 105C and blown into a bottle. PBI currently has 12 injection molding and 32 blow molding machines. On average, each machine incurs $24,000 of maintenance and depreciation cost per year. Plant maintenance requires shutting down all the machines. It is scheduled once a year and is performed by Molding Technology LLC. Due to staffng constraints, Molding Technology LLC can only perform maintenance in March, which requires shutting down the plant for 2.5 working days, or in July, which requires shutting down the plant for 5 working days. Each injection molding machine requires one operator and can produce 0.5 thousand pounds of PET preform per hour. The material cost for 1000 lb of PET preform is $30. Each blow molding machine requires one operator and can produce 0.2 thousand pounds of PET bottle per hour. Currently, PBI has 36 skilled operators that can operate both types of machines. Each operator is paid a monthly salary of $3200 and works a maximum of 8 h/day. There are 20 working days each month. In addition, each operator can work a maximum of 40 h of overtime a month, with an hourly pay of $30. A new operator requires 80 h of training before he/she can start operating a machine. Laying off an operator costs $4500. The inventory holding cost is $10 per month for 1000 lb of PET preform and $50 per month for 1000 lb of PET bottle. The backlog cost of PET bottle is $70 per thousand pounds per month. PBI strives to provide the bestquality products to its customer. It evaluates all potential subcontractors and found that a number of subcontractors can provide high-quality PET preform at a cost of $80 (including raw material cost) per thousand pounds. However, no subcontractors can provide PET bottles at a level of quality that is acceptable to PBI. The forecasted demand for the next year is shown in Table 3.12. PBI has no inventory and backlog at the beginning of the year. It does not want to hold any inventory or maintain any backlog at the end of the year. Develop an aggregate plan for PBI and explain how you make the following decisions:

Q1. When to build up PET preform inventory and when to purchase it from subcontractors?

Q2. When to schedule plant maintenance?

Q3. What is the cost that PBI is expected to incur?

PET Bottle Demand Forecast (in 1000lb ) PET Bottle Demand Forecast (in 1000lb )Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started