Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please answer fully and completely [3] The liquid phase reaction A+B C + D is catalyzed by a solid catalyst in a parallel-tube PBR (see

Please answer fully and completely

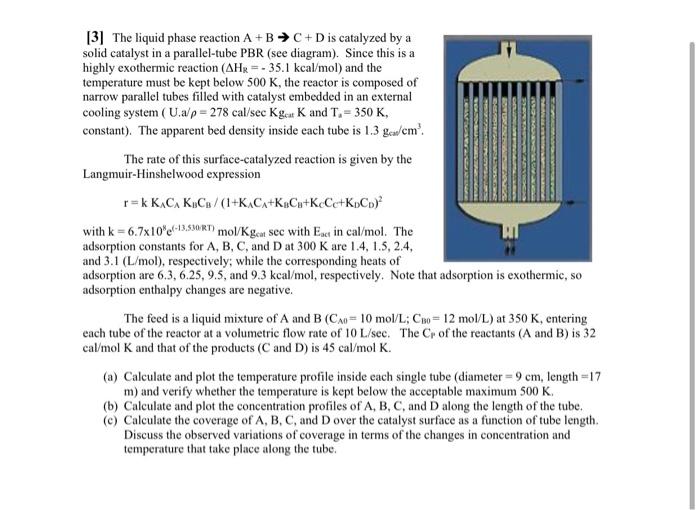

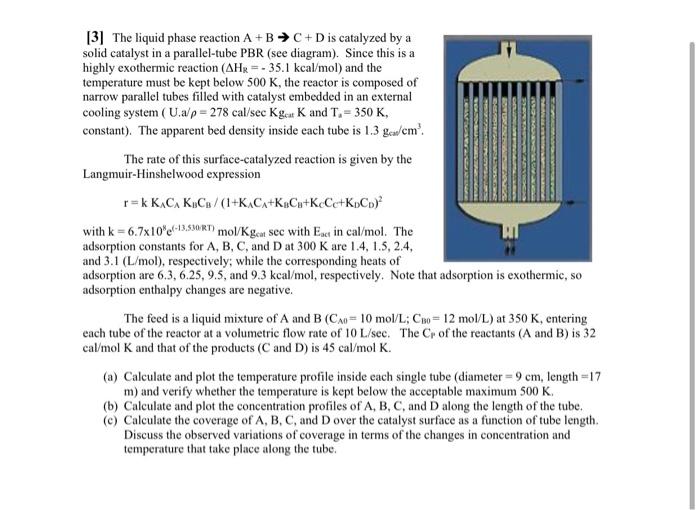

[3] The liquid phase reaction A+B C + D is catalyzed by a solid catalyst in a parallel-tube PBR (see diagram). Since this is a highly exothermic reaction (AHR = - 35.1 kcal/mol) and the temperature must be kept below 500 K, the reactor is composed of narrow parallel tubes filled with catalyst embedded in an external cooling system (U.alp = 278 cal/sec Kgeat K and T. = 350 K, constant). The apparent bed density inside each tube is 1.3 Leadem The rate of this surface-catalyzed reaction is given by the Langmuir-Hinshelwood expression rak KACAK,Cg/(1+KACx+KxCu+KcCc+KCD) with k = 6.7x10%-13.500RT) mol/Kgcat sec with Ese in cal/mol. The adsorption constants for A, B, C, and Dat 300 K are 1.4, 1.5, 2.4, and 3.1 (L/mol), respectively, while the corresponding heats of adsorption are 6.3, 6.25, 9.5, and 9.3 kcal/mol, respectively. Note that adsorption is exothermic, so adsorption enthalpy changes are negative. The feed is a liquid mixture of A and B (CA= 10 mol/L; Cso = 12 mol/L) at 350 K, entering each tube of the reactor at a volumetric flow rate of 10 L/sec. The Cp of the reactants (A and B) is 32 cal/mol K and that of the products (C and D) is 45 cal/mol K. (a) Calculate and plot the temperature profile inside each single tube (diameter = 9 cm, length=17 m) and verify whether the temperature is kept below the acceptable maximum 500 K (b) Calculate and plot the concentration profiles of A, B, C, and D along the length of the tube. (c) Calculate the coverage of A, B, C, and D over the catalyst surface as a function of tube length. Discuss the observed variations of coverage in terms of the changes in concentration and temperature that take place along the tube. [3] The liquid phase reaction A+B C + D is catalyzed by a solid catalyst in a parallel-tube PBR (see diagram). Since this is a highly exothermic reaction (AHR = - 35.1 kcal/mol) and the temperature must be kept below 500 K, the reactor is composed of narrow parallel tubes filled with catalyst embedded in an external cooling system (U.alp = 278 cal/sec Kgeat K and T. = 350 K, constant). The apparent bed density inside each tube is 1.3 Leadem The rate of this surface-catalyzed reaction is given by the Langmuir-Hinshelwood expression rak KACAK,Cg/(1+KACx+KxCu+KcCc+KCD) with k = 6.7x10%-13.500RT) mol/Kgcat sec with Ese in cal/mol. The adsorption constants for A, B, C, and Dat 300 K are 1.4, 1.5, 2.4, and 3.1 (L/mol), respectively, while the corresponding heats of adsorption are 6.3, 6.25, 9.5, and 9.3 kcal/mol, respectively. Note that adsorption is exothermic, so adsorption enthalpy changes are negative. The feed is a liquid mixture of A and B (CA= 10 mol/L; Cso = 12 mol/L) at 350 K, entering each tube of the reactor at a volumetric flow rate of 10 L/sec. The Cp of the reactants (A and B) is 32 cal/mol K and that of the products (C and D) is 45 cal/mol K. (a) Calculate and plot the temperature profile inside each single tube (diameter = 9 cm, length=17 m) and verify whether the temperature is kept below the acceptable maximum 500 K (b) Calculate and plot the concentration profiles of A, B, C, and D along the length of the tube. (c) Calculate the coverage of A, B, C, and D over the catalyst surface as a function of tube length. Discuss the observed variations of coverage in terms of the changes in concentration and temperature that take place along the tube

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started