Answered step by step

Verified Expert Solution

Question

1 Approved Answer

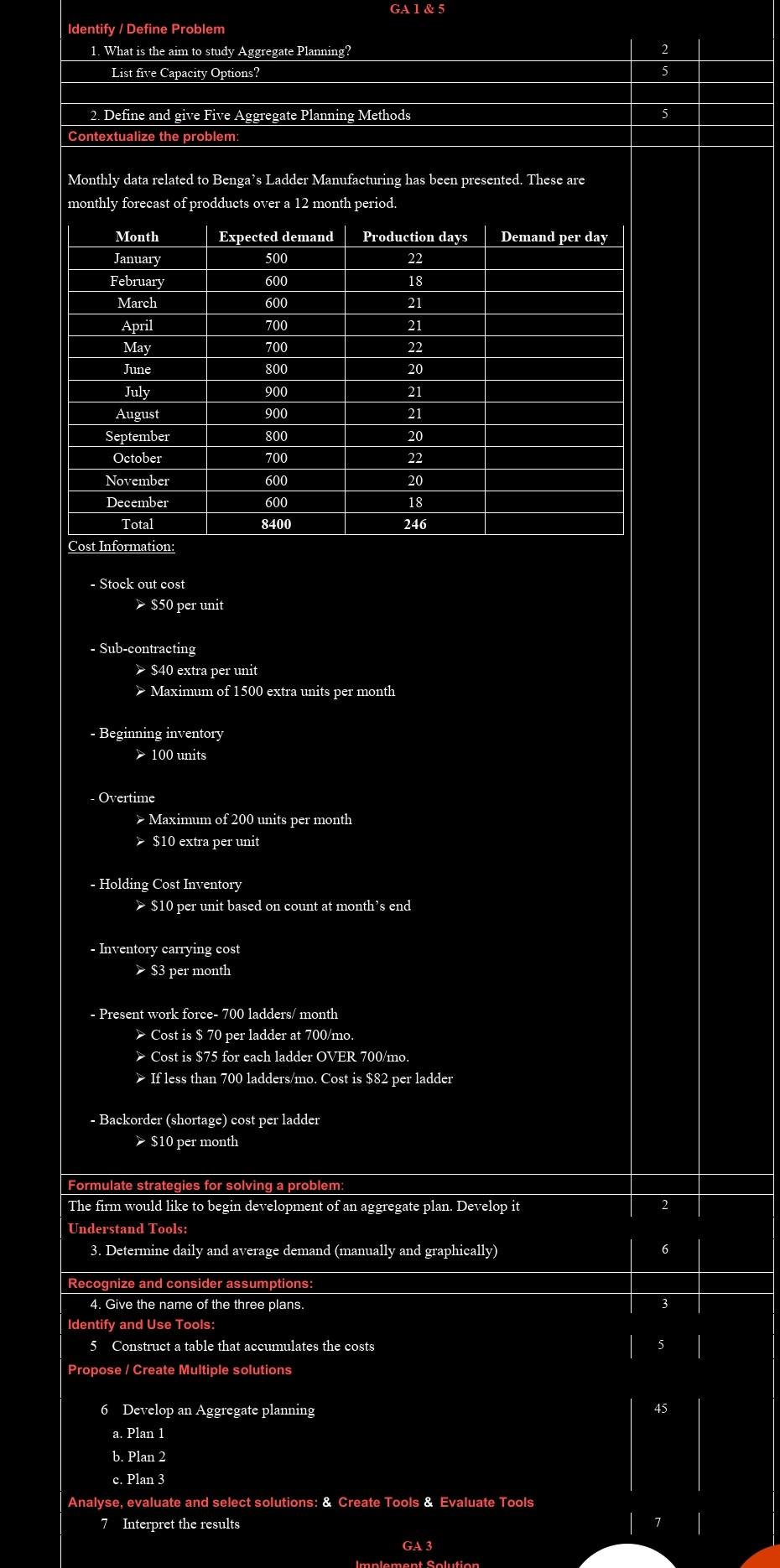

Please answer. No 3& 4 but if it's only one question please answer no. 4 GA1 & 5 Identify / Define Problem 1. What is

Please answer. No 3& 4 but if it's only one question please answer no. 4

GA1 & 5 Identify / Define Problem 1. What is the aim to study Aggregate Planning? List five Capacity Options? 2 5 5 2. Define and give Five Aggregate Planning Methods Contextualize the problem: Monthly data related to Benga's Ladder Manufacturing has been presented. These are monthly forecast of prodducts over a 12 month period. Production days Demand per day Expected demand 500 22 600 18 21 600 700 700 800 Month January February March April May June July August September October November December Total Cost Information: 21 22 20 21 21 900 900 800 20 700 22 600 20 600 18 8400 246 - Stock out cost $50 per unit Sub-contracting $40 extra per unit Maximum of 1500 extra units per month - Beginning inventory > 100 units Overtime Maximum of 200 units per month $10 extra per unit - Holding Cost Inventory $10 per unit based on count at month's end - Inventory carrying cost $3 per month - Present work force- 700 ladders/ month Cost is $ 70 per ladder at 700/mo. Cost is $75 for each ladder OVER 700/mo. If less than 700 ladders/mo. Cost is $82 per ladder - Backorder (shortage) cost per ladder $10 per month 2 Formulate strategies for solving a problem: The firm would like to begin development of an aggregate plan. Develop it Understand Tools: 3. Determine daily and average demand (manually and graphically) 6 3 Recognize and consider assumptions: 4. Give the name of the three plans. Identify and Use Tools: 5 Construct a table that accumulates the costs Propose / Create Multiple solutions 45 6 Develop an Aggregate planning a. Plan 1 b. Plan 2 c. Plan 3 Analyse, evaluate and select solutions: & Create Tools & Evaluate Tools 7 Interpret the results GA3 Implement Solution 7 GA1 & 5 Identify / Define Problem 1. What is the aim to study Aggregate Planning? List five Capacity Options? 2 5 5 2. Define and give Five Aggregate Planning Methods Contextualize the problem: Monthly data related to Benga's Ladder Manufacturing has been presented. These are monthly forecast of prodducts over a 12 month period. Production days Demand per day Expected demand 500 22 600 18 21 600 700 700 800 Month January February March April May June July August September October November December Total Cost Information: 21 22 20 21 21 900 900 800 20 700 22 600 20 600 18 8400 246 - Stock out cost $50 per unit Sub-contracting $40 extra per unit Maximum of 1500 extra units per month - Beginning inventory > 100 units Overtime Maximum of 200 units per month $10 extra per unit - Holding Cost Inventory $10 per unit based on count at month's end - Inventory carrying cost $3 per month - Present work force- 700 ladders/ month Cost is $ 70 per ladder at 700/mo. Cost is $75 for each ladder OVER 700/mo. If less than 700 ladders/mo. Cost is $82 per ladder - Backorder (shortage) cost per ladder $10 per month 2 Formulate strategies for solving a problem: The firm would like to begin development of an aggregate plan. Develop it Understand Tools: 3. Determine daily and average demand (manually and graphically) 6 3 Recognize and consider assumptions: 4. Give the name of the three plans. Identify and Use Tools: 5 Construct a table that accumulates the costs Propose / Create Multiple solutions 45 6 Develop an Aggregate planning a. Plan 1 b. Plan 2 c. Plan 3 Analyse, evaluate and select solutions: & Create Tools & Evaluate Tools 7 Interpret the results GA3 Implement Solution 7Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started