please answer number one

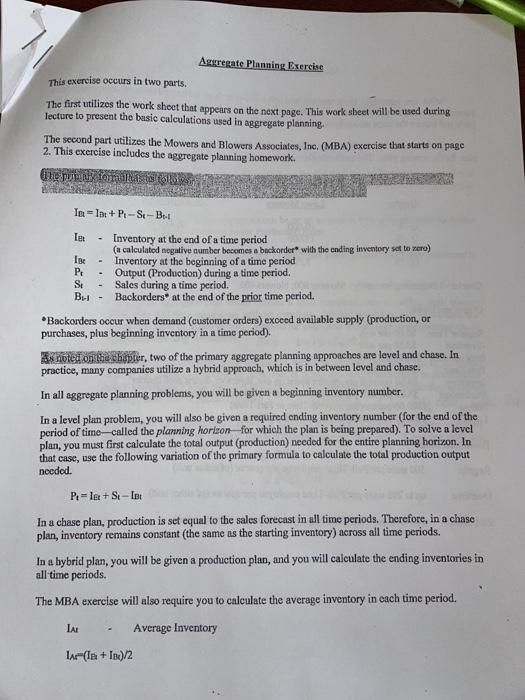

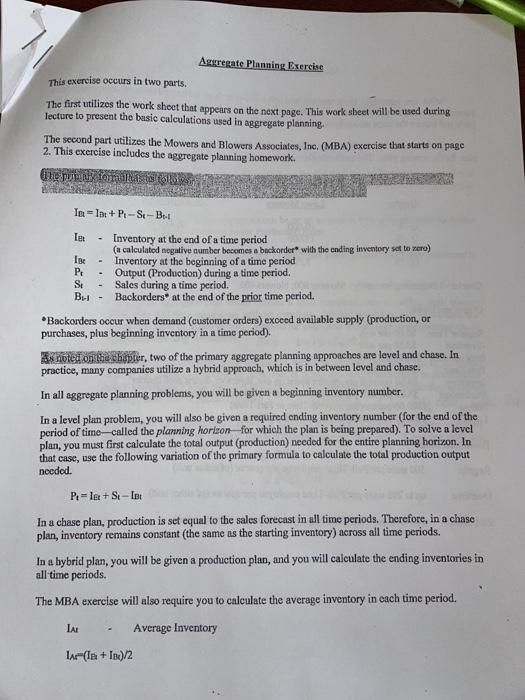

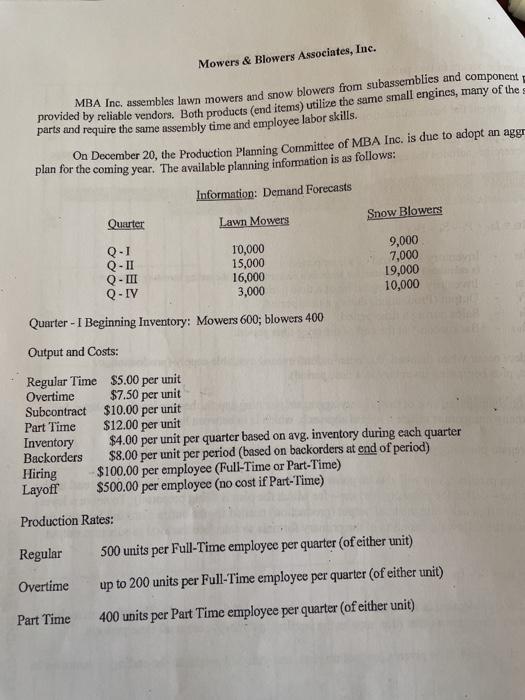

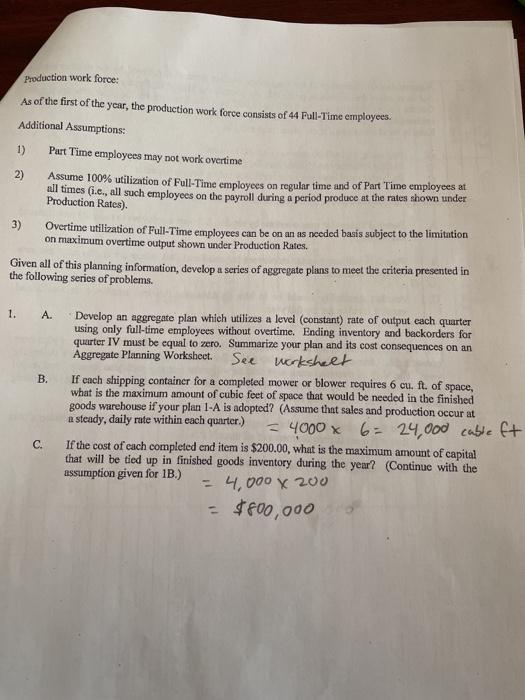

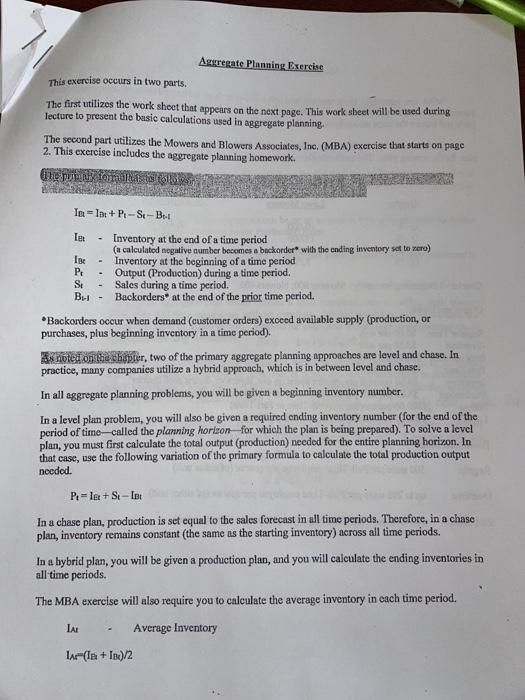

Aggregate Planning Exercise This exercise occurs in two parts. The first utilizes the work sheet that appears on the next page. This work sheet will be used during lecture to present the basic calculations used in aggregate planning, The second part utilizes the Mowers and Blowers Associates, Inc. (MBA) exercise that starts on page 2. This exercise includes the aggregate planning homework Que tot 180 In lat + Pe-St-Bar la Inventory at the end of a time period (a calculated negative number becomes a backorder with the ending inventory set to nero) IBC Inventory at the beginning of a time period PE Output (Production) during a time period. St Sales during a time period. BH - Backorders at the end of the prior time period. *Backorders occur when demand (customer orders) exceed available supply (production, or purchases, plus beginning inventory in a time period). smotabipler, two of the primary aggregate planning approaches are level and chase. In practice, many companies utilize a hybrid approach, which is in between level and chase. In all aggregate planning problems, you will be given a beginning inventory mumber. In a level plan problem, you will also be given a required ending inventory number (for the end of the period of time called the planning horizon--for which the plan is being prepared). To solve a level plan, you must first calculate the total output (production) needed for the entire planning horizon. In that case, use the following variation of the primary formula to calculate the total production output needed. Perla + Se-In In a chase plan, production is set equal to the sales forecast in all time periods. Therefore, in a chase plan, inventory remains constant (the same as the starting inventory) across all time periods. In a hybrid plan, you will be given a production plan, and you will calculate the ending inventories in all time periods. The MBA exercise will also require you to calculate the average inventory in each time period. IA Average Inventory l-(la + Ise)/2 Mowers & Blowers Associates, Inc. MBA Inc. assembles lawn mowers and snow blowers from subassemblies and component provided by reliable vendors. Both products (end items) utilize the same small engines, many of the parts and require the same assembly time and employee labor skills. On Docember 20, the Production Planning Committee of MBA Inc. is due to adopt an agg plan for the coming year. The available planning information is as follows: Information: Demand Forecasts Snow Blowers Quarter Lawn Mowers Q-1 Q- II - III Q-IV 10,000 15,000 16,000 3,000 9,000 7,000 19,000 10,000 Quarter - I Beginning Inventory: Mowers 600; blowers 400 Output and Costs: Regular Time $5.00 per unit Overtime $7.50 per unit Subcontract $10.00 per unit Part Time $12.00 per unit Inventory $4.00 per unit per quarter based on avg. inventory during each quarter Backorders $8.00 per unit per period (based on backorders at end of period) Hiring $100.00 per employee (Full-Time or Part-Time) Layoff $500.00 per employee (no cost if Part-Time) Production Rates: Regular Overtime 500 units per Full-Time employee per quarter of either unit) up to 200 units per Full-Time employee per quarter of either unit) 400 units per Part Time employee per quarter (of either unit) Part Time Production work force. As of the first of the year, the production work force consists of 44 Full-Time employees Additional Assumptions: 1) Part Time employees may not work overtime 2) Assume 100% utilization of Full-Time employees on regular time and of Part Time employees at all times (1.c., all such employees on the payroll during a period produce at the rates shown under Production Rates). 3) Overtime utilization of Full-Time employees can be on an as needed basis subject to the limitation on maximum overtime output shown under Production Rates. Given all of this planning information, develop a series of aggregate plans to meet the criteria presented in the following series of problems. 1. A. B. Develop an aggregate plan which utilizes a level (constant) rate of output each quarter using only full-time employees without overtime. Ending inventory and backorders for quarter IV must be equal to zero. Summarize your plan and its cost consequences on an Aggregate Planning Worksheet. See workshelt If each shipping container for a completed mower or blower requires 6 cu. ft. of space, what is the maximum amount of cubic feet of space that would be needed in the finished goods warehouse if your plan 1-A is adopted? (Assume that sales and production occur at a steady, daily rate within each quarter.) = 4000 x 6= 24,000 cable et If the cost of each completed end item is $200.00, what is the maximum amount of capital that will be tied up in finished goods inventory during the year? (Continue with the assumption given for 1B.) - 4.000 x 200 = $800,000 Aggregate Planning Exercise This exercise occurs in two parts. The first utilizes the work sheet that appears on the next page. This work sheet will be used during lecture to present the basic calculations used in aggregate planning, The second part utilizes the Mowers and Blowers Associates, Inc. (MBA) exercise that starts on page 2. This exercise includes the aggregate planning homework Que tot 180 In lat + Pe-St-Bar la Inventory at the end of a time period (a calculated negative number becomes a backorder with the ending inventory set to nero) IBC Inventory at the beginning of a time period PE Output (Production) during a time period. St Sales during a time period. BH - Backorders at the end of the prior time period. *Backorders occur when demand (customer orders) exceed available supply (production, or purchases, plus beginning inventory in a time period). smotabipler, two of the primary aggregate planning approaches are level and chase. In practice, many companies utilize a hybrid approach, which is in between level and chase. In all aggregate planning problems, you will be given a beginning inventory mumber. In a level plan problem, you will also be given a required ending inventory number (for the end of the period of time called the planning horizon--for which the plan is being prepared). To solve a level plan, you must first calculate the total output (production) needed for the entire planning horizon. In that case, use the following variation of the primary formula to calculate the total production output needed. Perla + Se-In In a chase plan, production is set equal to the sales forecast in all time periods. Therefore, in a chase plan, inventory remains constant (the same as the starting inventory) across all time periods. In a hybrid plan, you will be given a production plan, and you will calculate the ending inventories in all time periods. The MBA exercise will also require you to calculate the average inventory in each time period. IA Average Inventory l-(la + Ise)/2 Mowers & Blowers Associates, Inc. MBA Inc. assembles lawn mowers and snow blowers from subassemblies and component provided by reliable vendors. Both products (end items) utilize the same small engines, many of the parts and require the same assembly time and employee labor skills. On Docember 20, the Production Planning Committee of MBA Inc. is due to adopt an agg plan for the coming year. The available planning information is as follows: Information: Demand Forecasts Snow Blowers Quarter Lawn Mowers Q-1 Q- II - III Q-IV 10,000 15,000 16,000 3,000 9,000 7,000 19,000 10,000 Quarter - I Beginning Inventory: Mowers 600; blowers 400 Output and Costs: Regular Time $5.00 per unit Overtime $7.50 per unit Subcontract $10.00 per unit Part Time $12.00 per unit Inventory $4.00 per unit per quarter based on avg. inventory during each quarter Backorders $8.00 per unit per period (based on backorders at end of period) Hiring $100.00 per employee (Full-Time or Part-Time) Layoff $500.00 per employee (no cost if Part-Time) Production Rates: Regular Overtime 500 units per Full-Time employee per quarter of either unit) up to 200 units per Full-Time employee per quarter of either unit) 400 units per Part Time employee per quarter (of either unit) Part Time Production work force. As of the first of the year, the production work force consists of 44 Full-Time employees Additional Assumptions: 1) Part Time employees may not work overtime 2) Assume 100% utilization of Full-Time employees on regular time and of Part Time employees at all times (1.c., all such employees on the payroll during a period produce at the rates shown under Production Rates). 3) Overtime utilization of Full-Time employees can be on an as needed basis subject to the limitation on maximum overtime output shown under Production Rates. Given all of this planning information, develop a series of aggregate plans to meet the criteria presented in the following series of problems. 1. A. B. Develop an aggregate plan which utilizes a level (constant) rate of output each quarter using only full-time employees without overtime. Ending inventory and backorders for quarter IV must be equal to zero. Summarize your plan and its cost consequences on an Aggregate Planning Worksheet. See workshelt If each shipping container for a completed mower or blower requires 6 cu. ft. of space, what is the maximum amount of cubic feet of space that would be needed in the finished goods warehouse if your plan 1-A is adopted? (Assume that sales and production occur at a steady, daily rate within each quarter.) = 4000 x 6= 24,000 cable et If the cost of each completed end item is $200.00, what is the maximum amount of capital that will be tied up in finished goods inventory during the year? (Continue with the assumption given for 1B.) - 4.000 x 200 = $800,000