Please answer the questions at end of the case analysis.

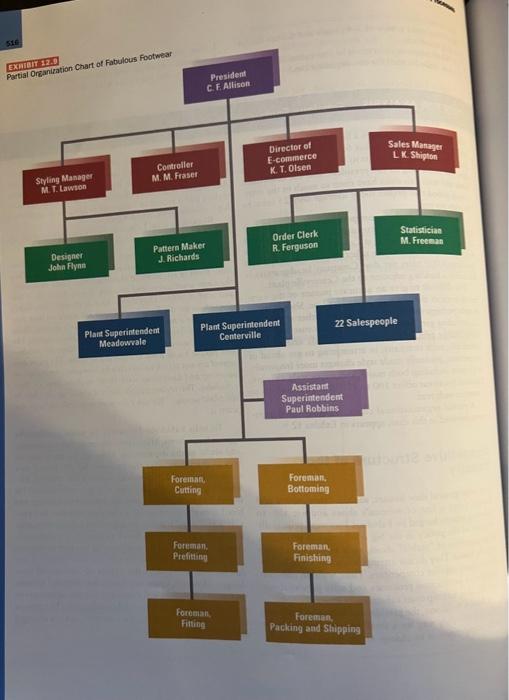

Fabulous Footwear produces a line of women's shoes that cell in the lower-price market for $27.99 to $29.99per pir. Profits averaged 30 cents to 50 cents per pair 10 years ago, but according to the president and the controller, labor and materials costs have risen so much in the interrening period that profits today average only 25 cents to 30 ents per pair. Production at both the company's plants totals 12,500 pairs per day. The two factories are located within a radius of 60 miles of Chicago: one at Centerville, which produces 4,500 pairs per day, and the other at Meadowvale, which produces 8,000 pairs per day. Company headquarters is located in a building adjacent to the Centerville plant. It is difficult to give an accurate picture of the number of items in the company's product line. Shoes change in style perhaps more rapidly than any other style product, including garments. This is chiefly because it is possible to change production processes quickly and because, historically, each company, in attempting to get ahead of competitors, gradually made style changes more frequently. At present, including both major and minor style changes, Fabulous Footwear offers 100 to 120 different products to customers each year. A partial organizational chart, showing the departments involved in this case, appears in Exhibit 12.9. Competitive Structure of the Industry Very large general shoe houses, such as International and Brown, carry a line of women's shoes and are able to undercut prices charged by Fabulous Footwear, principally because of the policy in the big companies of producing large numbers of "stable" shoes, such as the plain pump and the loafer. They do not attempt to change styles as rap. idly as their smaller competitors. Thus, without constant changes in production processes and sales presentations, they are able to keep costs substantially lower. Charles F. Allison, the president of Fabulous Footwear, feels that the only way for a small independent company to be competitive is to change styles frequently, taking advantage of the flexibility of a small organization to create designs that appeal to customers. Thus, demand can be created and a price set high enough to make a profit. Allison, incidentally, appears to have an artistic talent in styling and a record of successful judgments in approving high-volume styles over the years. Regarding how Fabulous Footwear differs from its large competitors, Allison has said: You sce, Brown and International Shoe Company both produce hundreds of thousands of the same pair of shoes. They store them in inventory at their factories. Their customers, the large wholesalers and retailers, simply know their line and send in orders. They do not have to change styles nearly as often as we do. Sometimes I wish we could do that, too. It makes for a mach more stable and orderily system. There is also less friction between people inside the company. The salespeople always know what they're selling; the production people know what is expected of them. The plant personnel are not shook up so often by someone coming in one morning and tampering with their machine lines or their schedules. The styling people are not shook up so often by the plant saying, "We can't do your new style the way you want it." To help Fabulous. Footwear be more competitive against larger firms, Allison recently created an e-commerce and social media department. Although his main interest was in marketing over the Internet, he also hoped new technology would help reduce some of the internal friction by giving people an easier way to communicate. He invested in sophisticated new information technology and hired consultants to set up a company intranet and provide a few days' training to upper and middle managers. Katherine Olsen came on board as director of e-commerce, charged primarily with coordinating Internet marketing and sales. When she took the job, she had visions of on day offering consumers the option of customized sho designs. However, Olsen was somewhat surprised to lear that most employees still refused to use the intranet eve for internal communication and coordination. The proce for deciding on new styles, for example, had not change since the 1980s. Major Style Changes in process to the foremin of the next departmena), the latter The decision about whether to put a certain afyle into prodoction requires information from a number of different people. Here is what typically happens in the company. it may be helpful to follow the organization chart (see Exhibit 12.9) tracing the procedure. M. T. Lawson, the styling manager, and his designer, joht Flyn, originate most of the ideas about shape, size of hecl, use of flat sole or hecls, and findings (the term used for orbanents attached to, but not part of, the shoesbows, straps, and so forth). They get their ideas principally. from rexding style and trade magazines or by copying topflight designers. Lawson corresponds with publications and friends in large stores in New York, Rome, and Paris to obtain pictures and samples of up-to-the-minute style innovations. Although be uses e-mail occasionally, Lawson preters telephone contact and receiving drawings or samples by overnighe mail. Then, he and Flyan discuss various ideas and come up with design options. When Liwson decides on a design, he takes a sketch to Alison, who cither approves or disapproves it. If Allison approves, he (Allison) then passes the sketch on to L. K. Shipton, the sales manager, to find ous what lasts (widths) sbould be chosen. Shipton, in turn, forwards the design to Martin Frceman, a statistician in the sales department, wo maintains summary information on customer demand for colors and lasts. To compile this information, Frecman visits salespeople wice a year to ger their opinions on the colors and lasts that are selling best, and he keeps records of shipmenes by coloc and by last. For these needs, he simply totals daca that are and by last. For these nceds, hesimply totals daca that are When Freeman has decided on the lasts and colors, he sends Allison a form that lists the colors and lasts in which the shoc should be produced. Allison, if he approves this the shoc should be produced. Alson, if he aproves this on to Jenna Richards, an expert pattern maket. Richards makes a paper pattern and then constructs a prototype in leather and paper. She sends this to Lawson, who in turn approves of disapproves it. He forwards any approved prototype to Allison. Allison, if he, too, approves, notifies Lrototype to Allisen. Alison, if he, too, approves, wotifies Lant to the superintendent of the Centerville plant. Only this plant produces small quantities of new or experimenthis plant produces small quantities of new or cxperimen tal styoes. This is referred to as a pilot run" by executives at the plant. Robbins then literally carries the prototype through the six production departments of the plant-from cutring to six production departments of the plant-irom cutring to finishing-discussang it wita cach forcman, who in turn in having a sammorks with employees on the machines in having a sam- When the finished ple lot of several thousand pairs made. When the finished lor is detivered by the finishing foreman to the shipping forcenan \{because of the importance of styling. Alison has 518 Part 5: Mankglng Dynamie Precesses John Flymn revealed: I was actwally becomeng dissarisfed wuth this tob, All thoe companies copy styles-it's a senterally accepted pinactice within the industry. But The pucked wp a nal forl for designs, and seccral tomes the swegeifel that the cumpary make all its own oricinal styles. We could make Fatrulcou Footucar a style leader and also increase ane wolarte. When I ask Lacson about this, be sarys it takes foo mach time for Whe designer no creape originals-that we have all ave call handle fo do rescarch in trade magazines atd mairtaits cantracts feeding in the reswlts of experts. Beides, be says our styles are standing the test of the marketplace. Projects X and Y Flyn also sid that he and Martin Freeman had frequently talked about the styling problem. They felt that: Allison is really a great presidert, and the company surcwhen he lost a lot of moncy ont bad judgments in stytes. Not many times-perhaps six or serven times in she last erigitecen monshs. Also, be is, of course, extremely busy as preaident of the corponation. He mast look after everything from f. rancing frott the banks fo burgaining with the anton. The result as that be is sometimes inaturilable to do his itying approeals for several days; or even ruo wecks, Io a buesiness hke this, that kind of delay cart cost money. It also makes bien sfightly edio. It tends, at times when be has many otiker things to do, fo make bint Look quickly at the styles we submit, or the prototypes Richards makes, or ewen the finnched sboes that are sent for approeval by the shipping forentan. Sometimes I worry that he makes two knds of errors. He simply nuber-stamps what uetee done, which makes send. ing these things to brim a waste of time. At other times be makes stapp indgments of bis osw, owernaling those of us who bave spent so mach time and expertise ont the sboc. We do think he has good jidgment, but he himself has sald at times that be wishes be had more time to comecntrate on styling and approval of prototypes and final prodiects. Fiyn further explained land this was corroborated by Frecman) that the two had worked out two plans, which they referred to as "project X " and "project Y* In the first, Fynn created an orizinal design that was not copicd from existing styles. Frecman thea gave special attention to color and last research for the shoe ind recommended a color line that didn't exactly fir past records on consumer purchases-but one he and Flynn thought would have "great consumer appeal," This design and color recotsmendation was accepted by Lawson and Allison, the shoe went into production and was one of the three top sellers during the calendar year. The latter two men did not know that the shoe was styled in a different way from the usual procedure; The revule of a second, similir project ( Y ) was pat into production the nexr yeaf, bet this rime sales were discoetinued aftet three werks: Problem Between Lawson and Robbins Frequently, perhaps 10 to 12 times a year, disagreement arises between Mel Lawson, manager of styling, and Paul Robbins, assitant to the superintendent of the Centerville planf. Robbins said: The styliog people don"t anderstand what it metans to prop The stying drece a shoe in the quastitics that we do, and to make the changes in prodactiont that we hate for They dram ap a style guichly, out of thir air. They do not realite that toe bare 4 lot of machimes shat buve to be adrusted and that some things thy drasm ap take mench longer on certain wachimes than oflecrs, thas crating a bortleneck in the production lise. If they pat a bow or strap in one positnon rather than another, it my moan teve hate ro keep prople idle on later mactines stule there is a pilesp on tee sene ink madhines on which thas complicated hatrle operation u performid. This couts the plant money. Furthemore, there are times ukee thoy get the prototype here Late, and eiterer the forentes and I work oucrtime or the trial rum won't get through in tirec to bave mese prodiction runs on new styles, to take the plaset eapacity laberated by auer stopping frohaction on ofd styles. Lavseer doesn't know much dbout production and sales and the shole company. I think all be does is to bring thoes dous bere to the plent, sort of like a messenger boy Why sbould be be so batd po get along with? He and' getring futid ary more than I am, and my prositices in the plant is piest as important as bis. Lawson, in turn, said that he has a difficult time getting along with Robbins: There are maxy times wher Robbins is fust werrasonable. I take protobyer to bim fue or six times a montb, and other minor style changes fo hin six or eight times. I fell him every time that we hate problems in getting these reatay but be knows onby aboart ohe plint, and relling hin doent? seem to do any good. Wben ure first poined the compury, ue got aloug all rigkt, but be bas gotten harder and barder to get along with, Other Problems Ralph Ferguson, the clerk in the sales department who receives orders from salespeople and forwards toesis fot production schedules to the two plant superintendenrs, has complained that the salespeople and Freeman are bypassing him in their practice of sending experimental shoe orders to Freeman. He insisted that his job description (one of only 519 wo writen descriptions in the company) gives him responsbility for receiving all orders throughout the company and for maintaining historical statistics on shipments. Both the salespeople and Freeman, on the other hand, sid that before rhey started the new practice (that is, when Ferguson still received the experimental shoe orders), there were at least 8 or 10 instances a year when these were delayed from 1 to 3 days on Ferguson's desk. They reported that Ferguson just wasn't interested in new styles, so the salespeople "just started sending them to Freeman." ferguson acknowledged that there were times of short delay, but said that there were good reasons for them: They [the salespeople and Freeman] are so interested in new designs, colors, and lasts that they can't understand the importance of a systematic bandling of the whole order procedure, including both old and new shoe styles. There must be accuracy. Sure, I give some priority to experimental orders, but sometimes when rush orders for existing company products are piling up, and when there's a lot of planning I have to do to allocate production befween Centerville and Meadowvale, I decide which comes firstprocessing of these, or processing the experimental shoe arders. Shipton is my boss, not the salespeople or Freeman. l'm going to insist that these orders come to me. The Push for New Technology Katherine Olsen believes many of these problems could be solved through better use of rechnology. She has Questions 1. How would you characterize the structure of Fabulous Footwear? Explain. 2. In what ways is the structure appropriate or inappropriate for frequent changes in shoe styles? What structure changes would you recommend? approached Charles Allison several times about the need to make greater use of the expensive and sophisticated computer information systems he had installed. Although Allison always agrees with her, he has so far done nothing to help solve the problem. Olsen thinks the new technology could dramatically improve coordination at Fabulous Footwear. Everyone needs to be working from the same data at the same timte. As soun as Lawson and Flynn come up with a new design, it should be posted on the intranet so all of us can be informed. And rveryone needs access to sales and order information, production schedules, and shipping deadlines. If everyone-from Allison down to the people in the production plants-uss kept up to date throughout the entire process, we wouldn't have all this confusion and bickering. But no one around bere wants to gue up any control-they all have their otwn little operations and don't want to share information with anyone else. For example, I somerimes don't even know there's a new style in the works until I get finished samples and photos. No one seems to recogmize that one of the buggest advantages of the Internet is to help stay ahead of changing styles. I know that Flym has a good feel for design, and we're not taking advantage of his abilities. But I also have information and ideas that could help this company keep pace with cbanges and re. ally stand out from the crowd. I don't know bow long we expect to remain competitive using this cumbersome, slow-moving process and putting out shoes that are al. ready behind the times. 3. If you were the CEO, how would you get employces to use the new information technology available within Fabulous Footwear