Question

Please answer This Question Value Stream Mapping (VSM) is one of the most significant lean manufacturing techniques to improve the production line of companies by

Please answer This Question

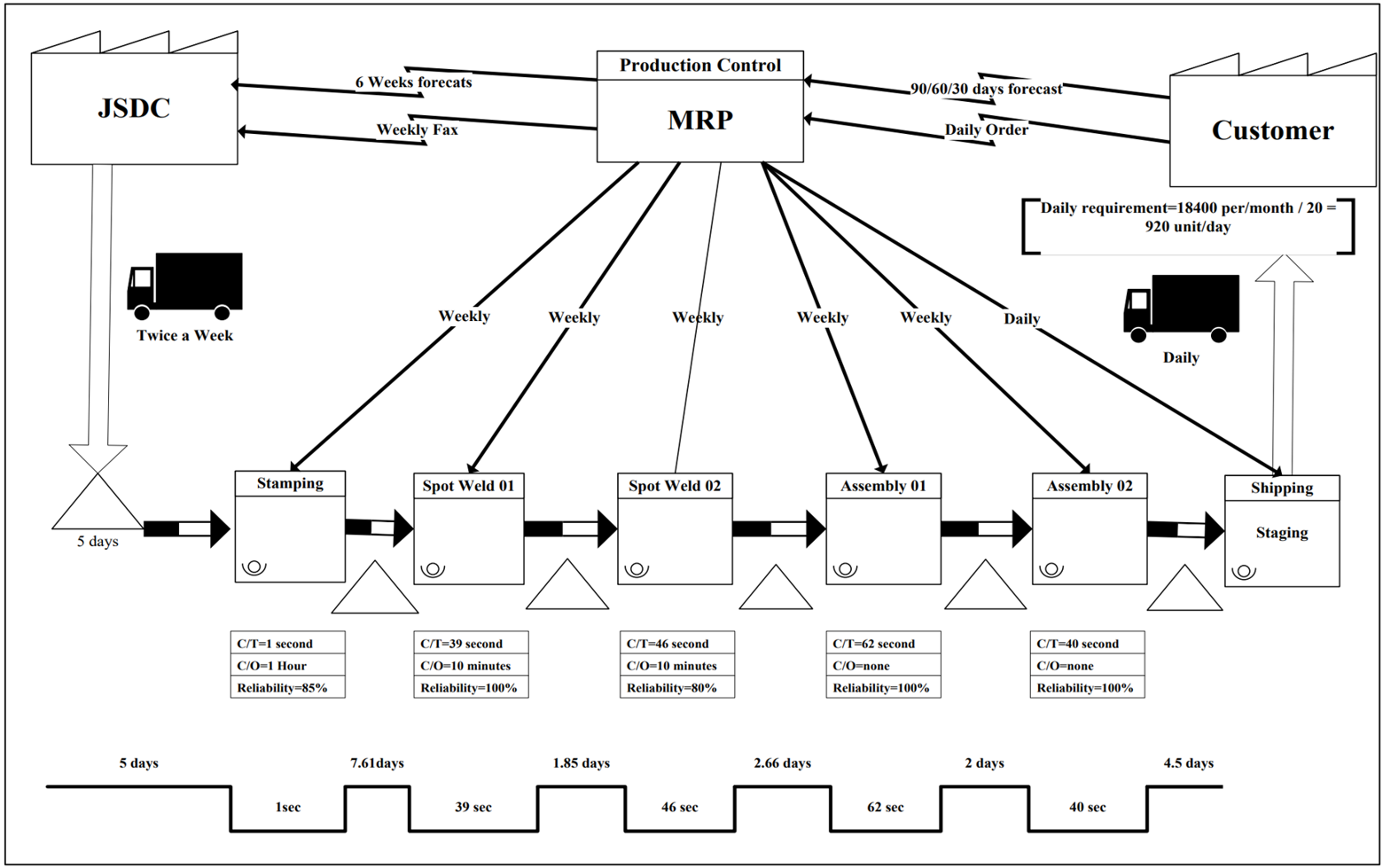

Value Stream Mapping (VSM) is one of the most significant lean manufacturing techniques to improve the production line of companies by decreasing waste and nonvalue added activities. The following VSM is for a company that produces several components for vehicle assembly lines. The process of production line includes cutting metal, welding, and subsequent assembly. Finally, the components are staged and shipped to the vehicle assembly factory on a daily basis. There is once a day shipment to the assembly factory by truck. The work time of this company is 20 days a month as well as two shifts in a day and eight hours working time in each shift, in addition, it includes 10 minutes breaks during each shift. After carefully studying the VSM, please answer the questions below:

1. What is the cycle time for the stamping process? (5 points) 2. What is the cycle time for the entire process or system (i.e. summation of all cycle times)? (10 points) 3. What is the system cycle time? (10 points) 4. What is the throughput time? (10 points) 5. What is the percent value-added time in this process? What is the percent non-value-added time in this process? Based on your understanding of the problem, which of the activities can be considered value-enabling (reasonable assumptions are accepted here), and based on your answer, what is the percent value-enabling time in this process? (20 points) 6. If the company has two shifts in a day and eight hours of working time in each shift, in addition, it includes 10 minutes breaks during each shift, and the demand was 920 daily required units of production, what is the takt time (in seconds per unit)? (15 points) 7. If the demand becomes 1000 vehicles per day, what is the takt time? (5 points) 8. What would you do in the second situation (referenced in part 7)? (10 points) 9. Develop a bar chart showing the processes with value-adding times in the system. Be sure to create a dotted line for the takt time calculated in part 6. According to the level loading lean technique (heijunka), what are the steps that can be taken to achieve a balanced workflow? Please comment on the results and explain your rationale (25 points). 10. Discuss your results and comment on the systems ability to handle the demand (10 points).

JSDC 5 days Twice a Week 5 days Stamping C/T-1 second C/O=1 Hour Reliability 85% 1sec 6 Weeks forecats Weekly Fax 7.61days Weekly Spot Weld 01 C/T 39 second C/O-10 minutes Reliability=100% 39 sec Weekly 1.85 days Production Control MRP Weekly Spot Weld 02 C/T=46 second C/O=10 minutes Reliability=80% 46 sec Weekly 2.66 days 90/60/30 days forecast" Weekly Assembly 01 C/T=62 second C/O=none Reliability 100% 62 sec Daily Order Daily 2 days Daily requirement-18400 per/month / 20 = 920 unit/day Assembly 02 C/T-40 second C/O=none Reliability 100% 40 sec Customer Daily 4.5 days Shipping StagingStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started