Question

The ABC company, a manufacturer of windows for residential buildings, hired a quality consultant to train the shift supervisors and selected line workers in statistical

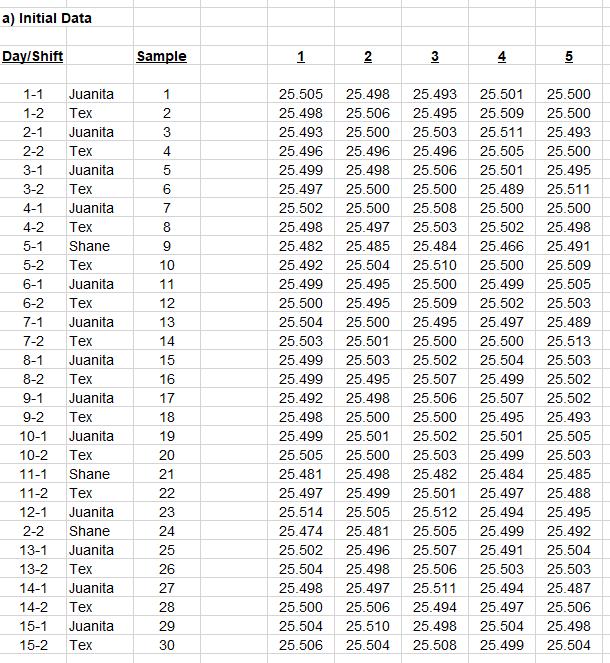

The ABC company, a manufacturer of windows for residential buildings, hired a quality consultant to train the shift supervisors and selected line workers in statistical process control methods. As a trial project, the plant manager wants to evaluate the capability of a critical cutting operation that he suspects might be the source of the gap problem. The nominal specification for this cutting operation is 25.500 inches with a tolerance of 0.030 inches. Thus, the upper and lower specifications are LSL = 25.470 and USL = 25.530 inch. The consultant suggested inspecting five consecutive window panels, per operator, in the middle of each shift over a 15-day period and recording the dimension of the cut. The data shown below shows 15 days’ data collected for each shift, by the operator.

a) Establish statistical control limits and evaluate the process capability of the process to meet specifications. You may consider the following questions: What do the initial control charts tell you? Do any out-of-control conditions exist? If the process is not in control, what might be the likely causes, based on the information that is available? What is the process capability? What do the process capability indexes tell the company? Is ABC facing a serious problem that needs to address?

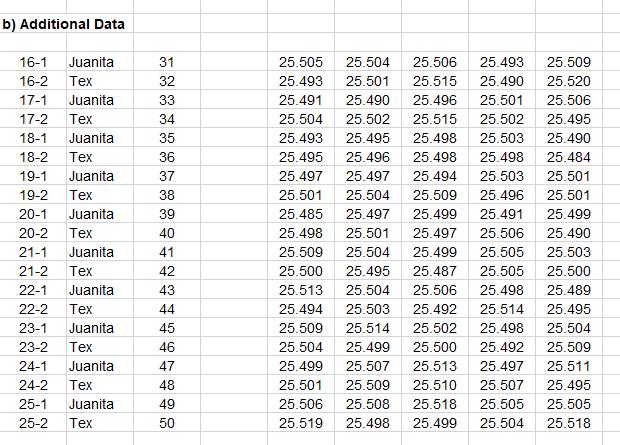

b) The plant manager implemented the recommendations that results from the initial study. Because of the success in using control charts, The ABC company made a decision to continue using them on the cutting operation. After establishing the control limit, additional samples were taken over the next 20 shifts, shown in the second part of the table below. Evaluate whether the process remains in control, and suggest any actions that should be taken. Consider the following issues: Does any evidence suggest that the process has changed relative to the established control limits? If any out-of-control patterns are suspected, what might be the cause? What should the company investigate?

a) Initial Data Day/Shift Sample 3 4 1-1 Juanita 1 25.505 25.498 25.493 25.501 25.500 1-2 Tex 2 25.498 25.506 25.495 25.509 25.500 2-1 Juanita 3 25.493 25.500 25.503 25.511 25.493 2-2 4 25.496 25.496 25.496 25.505 25.500 3-1 Juanita 25.499 25.498 25.506 25.501 25.495 3-2 6 25.497 25.500 25.500 25.489 25.511 4-1 Juanita 7 25.502 25.500 25.508 25.500 25.500 4-2 8. 25.498 25.497 25.503 25.502 25.498 5-1 Shane 9 25.482 25.485 25.484 25.466 25.491 5-2 10 25.492 25.504 25.510 25.500 25.509 6-1 Juanita 11 25.499 25.495 25.500 25.499 25.505 6-2 12 25.500 25.495 25.509 25.502 25.503 7-1 Juanita 13 25.504 25.500 25.495 25.497 25.489 7-2 14 25.503 25.501 25.500 25.500 25.513 8-1 Juanita 15 25.499 25.503 25.502 25.504 25.503 8-2 16 25.499 25.495 25.507 25.499 25.502 9-1 Juanita 17 25.492 25.498 25.506 25.507 25.502 9-2 18 25.498 25.500 25.500 25.495 25.493 10-1 Juanita 19 25.499 25.501 25.502 25.501 25.505 10-2 20 25.505 25.500 25.503 25.499 25.503 11-1 Shane 21 25.481 25.498 25.482 25.484 25.485 11-2 22 25.497 25.499 25.501 25.497 25.488 12-1 Juanita 23 25.514 25.505 25.512 25.494 25.495 2-2 Shane 24 25.474 25.481 25.505 25.499 25.492 13-1 Juanita 25 25.502 25.496 25.507 25.491 25.504 13-2 26 25.504 25.498 25.506 25.503 25.503 14-1 Juanita 27 25.498 25.497 25.511 25.494 25.487 14-2 28 25.500 25.506 25.494 25.497 25.506 15-1 Juanita 29 25.504 25.510 25.498 25.504 25.498 15-2 30 25.506 25.504 25.508 25.499 25.504

Step by Step Solution

3.40 Rating (156 Votes )

There are 3 Steps involved in it

Step: 1

ANSWER There are Huge deviation in the process at 51 111 1...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started