Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please Donot copy other answer from Chegg, thx The Move-It Company has two plants producing forklift trucks that then are shipped to three distribution centers.

Please Donot copy other answer from Chegg, thx

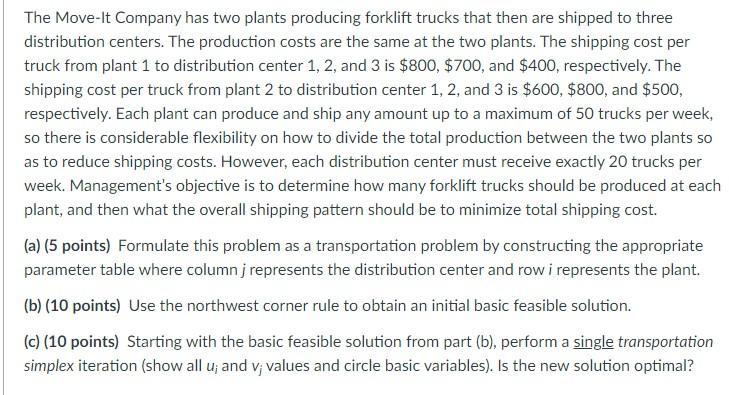

The Move-It Company has two plants producing forklift trucks that then are shipped to three distribution centers. The production costs are the same at the two plants. The shipping cost per truck from plant 1 to distribution center 1, 2, and 3 is $800, $700, and $400, respectively. The shipping cost per truck from plant 2 to distribution center 1, 2, and 3 is $600, $800, and $500, respectively. Each plant can produce and ship any amount up to a maximum of 50 trucks per week, so there is considerable flexibility on how to divide the total production between the two plants so as to reduce shipping costs. However, each distribution center must receive exactly 20 trucks per week. Management's objective is to determine how many forklift trucks should be produced at each plant, and then what the overall shipping pattern should be to minimize total shipping cost. (a) (5 points) Formulate this problem as a transportation problem by constructing the appropriate parameter table where column j represents the distribution center and row i represents the plant. (b) (10 points) Use the northwest corner rule to obtain an initial basic feasible solution. (c) (10 points) Starting with the basic feasible solution from part (b), perform a single transportation simplex iteration (show all u and v; values and circle basic variables). Is the new solution optimal? The Move-It Company has two plants producing forklift trucks that then are shipped to three distribution centers. The production costs are the same at the two plants. The shipping cost per truck from plant 1 to distribution center 1, 2, and 3 is $800, $700, and $400, respectively. The shipping cost per truck from plant 2 to distribution center 1, 2, and 3 is $600, $800, and $500, respectively. Each plant can produce and ship any amount up to a maximum of 50 trucks per week, so there is considerable flexibility on how to divide the total production between the two plants so as to reduce shipping costs. However, each distribution center must receive exactly 20 trucks per week. Management's objective is to determine how many forklift trucks should be produced at each plant, and then what the overall shipping pattern should be to minimize total shipping cost. (a) (5 points) Formulate this problem as a transportation problem by constructing the appropriate parameter table where column j represents the distribution center and row i represents the plant. (b) (10 points) Use the northwest corner rule to obtain an initial basic feasible solution. (c) (10 points) Starting with the basic feasible solution from part (b), perform a single transportation simplex iteration (show all u and v; values and circle basic variables). Is the new solution optimalStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started