Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please give me Q1(iii), Q2, Q3(i), Q4, Q5 2) Assignment 1: Design of batch processes Process description A batch process is operated with the following

please give me Q1(iii), Q2, Q3(i), Q4, Q5

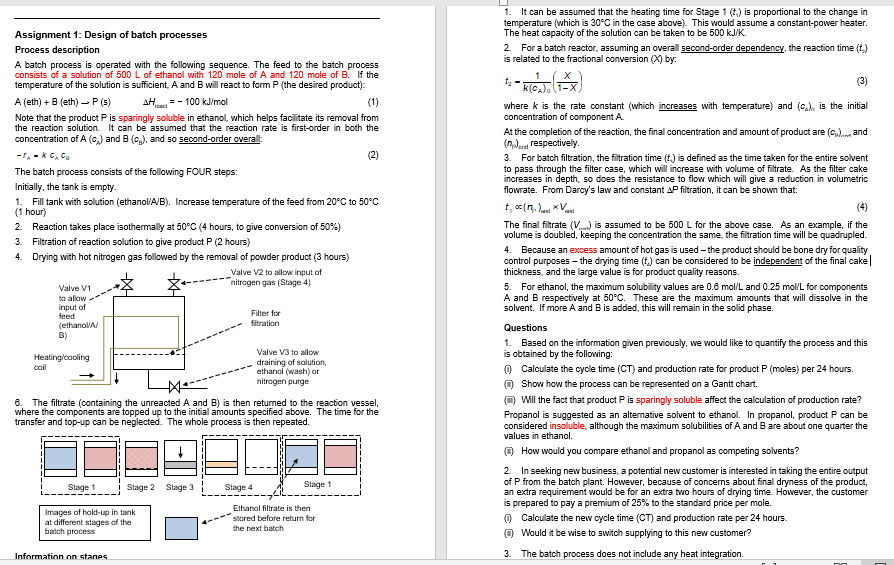

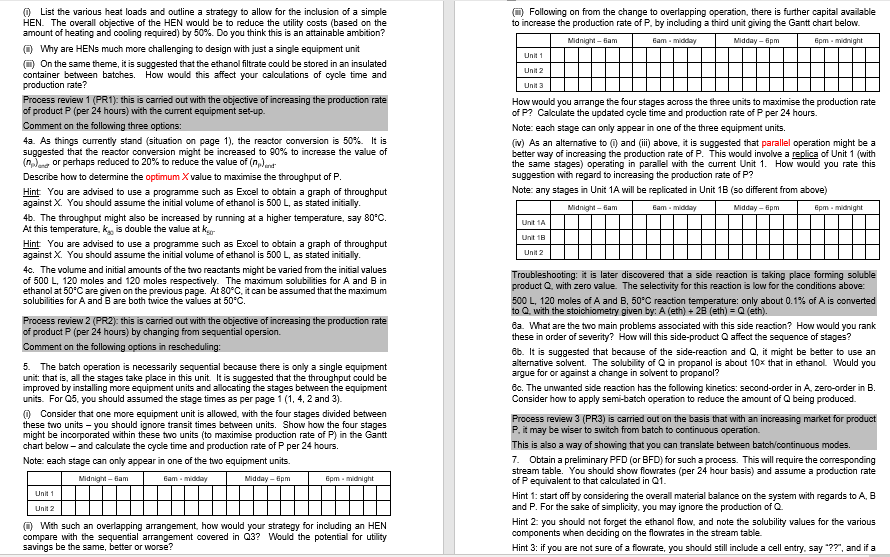

2) Assignment 1: Design of batch processes Process description A batch process is operated with the following sequence. The feed to the batch process consists of a solution of 500 L of ethanol with 120 mole of A and 120 mole of B. If the temperature of the solution is sufficient. A and B will react to form P (the desired product): A eth) + B (eth) - P(s) AH-100 kJ/mol (1) Note that the product P is sparingly soluble in ethanol, which helps facilitate its removal from the reaction solution. It can be assumed that the reaction rate is first-order in both the concentration of A (C) and (c), and so second-order overall -- K GACH The batch process consists of the following FOUR steps: Initially, the tank is empty 1. Fill tank with solution (ethanol/A/B). Increase temperature of the feed from 20C to 50C (1 hour) 2. Reaction takes place isothermally at 50C (4 hours, to give conversion of 50%) 3. Filtration of reaction solution to give product P (2 hours) 4. Drying with hot nitrogen gas followed by the removal of powder product (3 hours) Valve V2 to allow input of Valve V1 nitrogen gas (Stage 4 to allow input of feed Filter for (ethanol filtration B) Heating cooling Valve V3 to allow cail draining of solution, ethanol (wash) or nitrogen purge 8. The filtrate (containing the unreacted A and B) is then returned to the reaction vessel, where the components are topped up to the initial amounts specified above. The time for the transfer and top-up can be neglected. The whole process is then repeated. 1. It can be assumed that the heating time for Stage 1 (4) is proportional to the change in temperature (which is 30C in the case above). This would assume a constant-power heater. The heat capacity of the solution can be taken to be 500 kJ/K. 2. For a batch reactor, assuming an overall second-order dependency, the reaction time (L.) is related to the fractional conversion (x) by: 1 (3) k(C.). 1-X where k is the rate constant (which increases with temperature) and (c), is the initial concentration of component A At the completion of the reaction, the final concentration and amount of product are (c. and (mand respectively 3. For batch filtration, the filtration time (t) is defined as the time taken for the entire solvent to pass through the filter case, which will increase with volume of filitrate. As the filter cake increases in depth, so does the resistance to flow which will give a reduction in volumetric flowrate. From Darcy's law and constant AP filtration, it can be shown that: ton...V (4) The final filtrate (V) is assumed to be 500 L for the above case. As an example, if the volume is doubled, keeping the concentration the same the filtration time will be quadrupled. 4. Because an excess amount of hot gas is used the product should be bone dry for quality, control purposes - the drying time (t.) can be considered to be independent of the final cake thickness, and the large value is for product quality reasons. 5. For ethanol, the maximum solubility values are 0.6 mol/L and 0.25 mol/L for components A and respectively at 50c. These are the maximum amounts that will dissolve in the solvent. If more A and B is added, this will remain in the solid phase. Questions 1. Based on the information given previously, we would like to quantify the process and this is obtained by the following: m Calculate the cycle time (CT) and production rate for product P (moles) per 24 hours. Show how the process can be represented on a Gantt chart. Will the fact that product Pis sparingly soluble affect the calculation of production rate? Propanol is suggested as an alternative solvent to ethanol. In propanol, product P can be considered insoluble, although the maximum solubilities of A and B are about one quarter the values in ethanol. How would you compare ethanol and propanol as competing solvents? 2 In seeking new business, a potential new customer is interested in taking the entire output of P from the batch plant. However, because of concerns about final dryness of the product, an extra requirement would be for an extra two hours of drying time. However, the customer is prepared to pay a premium of 25% to the standard price per mole. 0 Calculate the new cycle time (CT) and production rate per 24 hours. Would it be wise to switch supplying to this new customer? 3. The batch process does not include any heat integration. Stage 1 Stage 2 Stage 3 Stage 4 Stage 1 Images of hold-up in tank at different stages of the batch process Ethanol filtrate is then stored before return for the next batch Information on stane @ Following on from the change to overlapping operation, there is further capital available to increase the production rate of P. by including a third unit giving the Gantt chart below. Midnight - Sam Eam. midday Midday - pm Epm.midnight Unit 1 Unit 2 Unit 3 How would you arrange the four stages across the three units to maximise the production rate of P? Calculate the updated cycle time and production rate of P per 24 hours. Note: each stage can only appear in one of the three equipment units. (iv) As an alternative to ) and (ii) above, it is suggested that parallel operation might be a better way of increasing the production rate of P. This would involve a replica of Unit 1 (with the same stages) operating in parallel with the current Unit 1. How would you rate this suggestion with regard to increasing the production rate of P? Note: any stages in Unit 1A will be replicated in Unit 18 (so different from above) Midnigham Eam midday Midday - 6pm Epm - midnight Unit 1 Unit 1 List the various heat loads and outline a strategy to allow for the inclusion of a simple HEN. The overall objective of the HEN would be to reduce the utility costs (based on the amount of heating and cooling required) by 50%. Do you think this is an attainable ambition? Why are HENs much more challenging to design with just a single equipment unit On the same theme, it is suggested that the ethanol filtrate could be stored in an insulated container between batches. How would this affect your calculations of cycle time and production rate? Process review 1 (PR1): this is carried out with the objective of increasing the production rate of product P (per 24 hours) with the current equipment set-up Comment on the following three options: 4a. As things currently stand (situation on page 1), the reactor conversion is 50%. It is suggested that the reactor conversion might be increased to 90% to increase the value of (n) or perhaps reduced to 20% to reduce the value of (net Describe how to determine the optimum X value to maximise the throughput of P. Hint You are advised to use a programme such as Excel to obtain a graph of throughput against X. You should assume the initial volume of ethanol is 500 L, as stated initially. 4b. The throughput might also be increased by running at a higher temperature, say 80C. At this temperature, ky is double the value at kr Hint You are advised to use a programme such as Excel to obtain a graph of throughput against X. You should assume the initial volume of ethanol is 500 L, as stated initially. 4c. The volume and initial amounts of the two reactants might be varied from the initial values of 500 L, 120 moles and 120 moles respectively. The maximum solubilities for A and B in ethanol at 50C are given on the previous page. At 80C, it can be assumed that the maximum solubilities for A and B are both twice the values at 50-C. Process review 2 (PR2): this is carried out with the objective of increasing the production rate of product P (per 24 hours) by changing from sequential opersion. Comment on the following options in rescheduling: 5. The batch operation is necessarily sequential because there is only a single equipment unit: that is all the stages take place in this unit. It is suggested that the throughput could be improved by installing more equipment units and allocating the stages between the equipment units. For Q5, you should assumed the stage times as per page 1 (1,4, 2 and 3). 0 Consider that one more equipment unit is allowed, with the four stages divided between these two units - you should ignore transit times between units. Show how the four stages might be incorporated within these two units (to maximise production rate of P) in the Gantt chart below- and calculate the cycle time and production rate of P per 24 hours. Note: each stage can only appear in one of the two equipment units. Midnight - Sam Gam.midday Midday - pm Epm.midnight Unit 2 Troubleshooting: it is later discovered that a side reaction is taking place forming soluble product Q with zero value. The selectivity for this reaction is low for the conditions above: 500 L, 120 moles of A and B, 50C reaction temperature: only about 0.1% of A is converted to Q with the stoichiometry given by: A (eth) + 25 (eth) = Q (eth). 6a. What are the two main problems associated with this side reaction? How would you rank these in order of severity? How will this side-product Q affect the sequence of stages? 6b. It is suggested that because of the side-reaction and Q, it might be better to use an alternative solvent. The solubility of Qin propanol is about 10x that in ethanol Would you argue for or against a change in solvent to propanol? 8c. The unwanted side reaction has the following kinetics: second-order in A zero-order in B. Consider how to apply semi-batch operation to reduce the amount of being produced Process review 3 (PR3) is carried out on the basis that with an increasing market for product P. it may be wiser to switch from batch to continuous operation This is also a way of showing that you can translate between batch/continuous modes. 7. Obtain a preliminary PFD (or BFD) for such a process. This will require the corresponding stream table. You should show flowrates (per 24 hour basis) and assume a production rate of P equivalent to that calculated in Q1. Hint 1: start off by considering the overall material balance on the system with regards to A, B and P. For the sake of simplicity, you may ignore the production of Q. Hint 2: you should not forget the ethanol flow, and note the solubility values for the various components when deciding on the flowrates in the stream table Hint 3: if you are not sure of a flowrate, you should still include a cell entry say "??", and if a Unit 1 Unit 2 With such an overlapping arrangement how would your strategy for including an HEN compare with the sequential arrangement covered in 03? Would the potential for utility savings be the same, better or worseStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started