Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please help me build this model During the next two months an automobile manufacturer must meet (on time) the following demands for trucks and cars:

please help me build this model

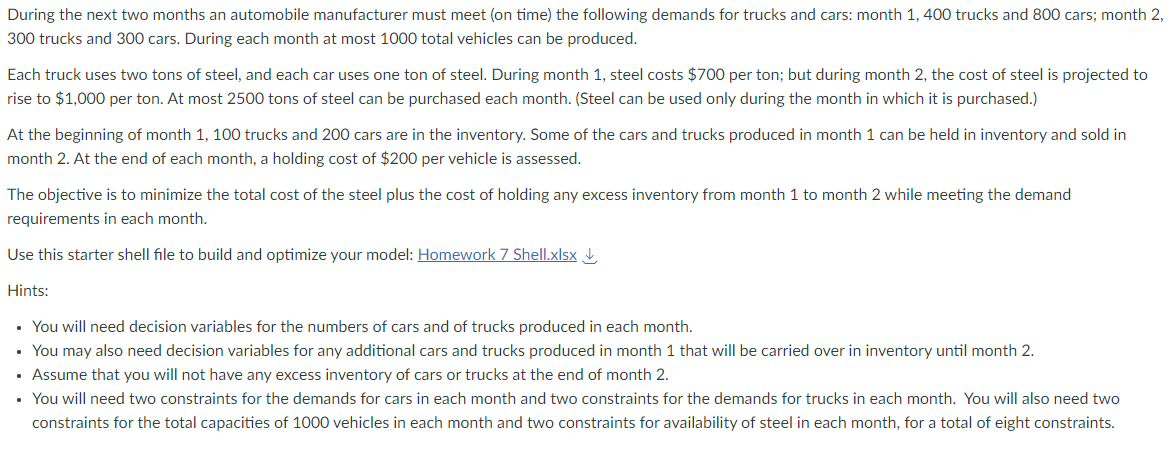

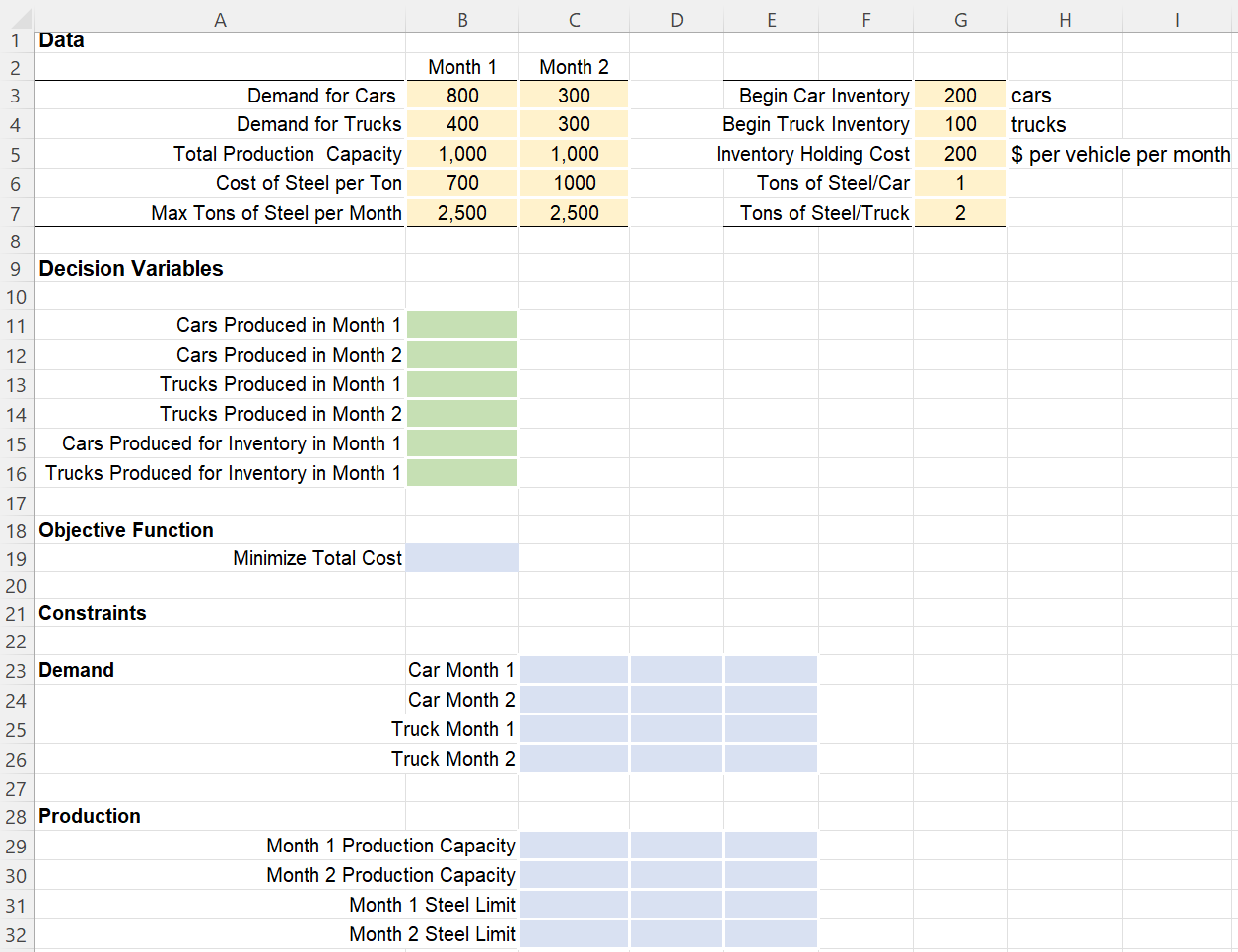

During the next two months an automobile manufacturer must meet (on time) the following demands for trucks and cars: month 1,400 trucks and 800 cars; month 300 trucks and 300 cars. During each month at most 1000 total vehicles can be produced. Each truck uses two tons of steel, and each car uses one ton of steel. During month 1 , steel costs $700 per ton; but during month 2, the cost of steel is projected to rise to $1,000 per ton. At most 2500 tons of steel can be purchased each month. (Steel can be used only during the month in which it is purchased.) At the beginning of month 1,100 trucks and 200 cars are in the inventory. Some of the cars and trucks produced in month 1 can be held in inventory and sold in month 2. At the end of each month, a holding cost of $200 per vehicle is assessed. The objective is to minimize the total cost of the steel plus the cost of holding any excess inventory from month 1 to month 2 while meeting the demand requirements in each month. Use this starter shell file to build and optimize your model: Homework 7 Shell.xlsx _ Hints: - You will need decision variables for the numbers of cars and of trucks produced in each month. - You may also need decision variables for any additional cars and trucks produced in month 1 that will be carried over in inventory until month 2. - Assume that you will not have any excess inventory of cars or trucks at the end of month 2. - You will need two constraints for the demands for cars in each month and two constraints for the demands for trucks in each month. You will also need two constraints for the total capacities of 1000 vehicles in each month and two constraints for availability of steel in each month, for a total of eight constraints. During the next two months an automobile manufacturer must meet (on time) the following demands for trucks and cars: month 1,400 trucks and 800 cars; month 300 trucks and 300 cars. During each month at most 1000 total vehicles can be produced. Each truck uses two tons of steel, and each car uses one ton of steel. During month 1 , steel costs $700 per ton; but during month 2, the cost of steel is projected to rise to $1,000 per ton. At most 2500 tons of steel can be purchased each month. (Steel can be used only during the month in which it is purchased.) At the beginning of month 1,100 trucks and 200 cars are in the inventory. Some of the cars and trucks produced in month 1 can be held in inventory and sold in month 2. At the end of each month, a holding cost of $200 per vehicle is assessed. The objective is to minimize the total cost of the steel plus the cost of holding any excess inventory from month 1 to month 2 while meeting the demand requirements in each month. Use this starter shell file to build and optimize your model: Homework 7 Shell.xlsx _ Hints: - You will need decision variables for the numbers of cars and of trucks produced in each month. - You may also need decision variables for any additional cars and trucks produced in month 1 that will be carried over in inventory until month 2. - Assume that you will not have any excess inventory of cars or trucks at the end of month 2. - You will need two constraints for the demands for cars in each month and two constraints for the demands for trucks in each month. You will also need two constraints for the total capacities of 1000 vehicles in each month and two constraints for availability of steel in each month, for a total of eight constraintsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started