Question: please help. Problem Statement: Xylenes are used as raw materials for the manufacturing of polyesters which are used for textile fibers, photographic film, and soft-drink

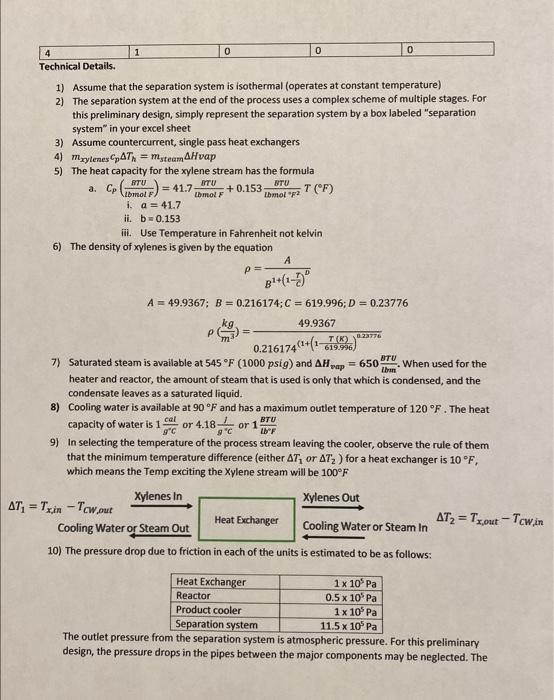

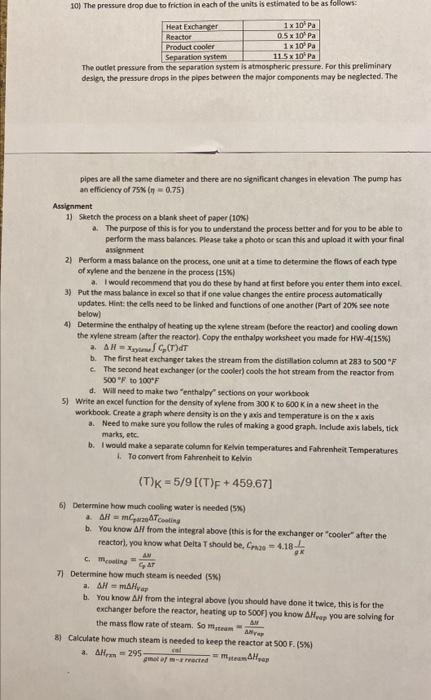

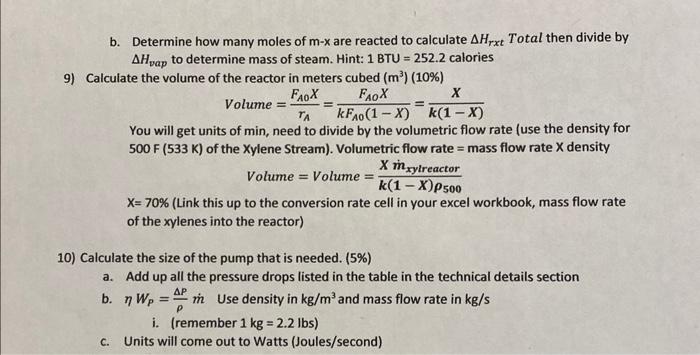

Problem Statement: Xylenes are used as raw materials for the manufacturing of polyesters which are used for textile fibers, photographic film, and soft-drink bottles. The process to be added to an existing facility involves the isomerization reactor where meta-xylenes (mx) is converted to ortho-xylenes (0x) and para-xylenes (px). Note that all three of these compounds are isomers (same elemental composition with different chemical structure). Therefore, they have the same molecular weight (MW=106). For our purposes here we will assume that equal amounts of 0x and px are produced so that the reaction proceeds as follows: 2mxrmox+px This liquid phase reaction is assumed to be irreversible and is approximated by first-order kinetics with a rate constant of kr=0.133min1. The reaction is slightly endothermic (Hreact= 295gmotofmxreactedcal ) The simplified process is described below. A liquid feed stream will enter the process at 2atm and a temperature off 77F at a rate of 1.15 million kg/day. The mass fractions of that feed stream are: The feed stream goes through a distillation column where 99% (by mass) of the benzene is removed in the distillate (the top of the distillation column at 80F and 1atm ), the small amount of benzene and the entire xylene stream comes out in the bottoms at atmospheric pressure ( 1atm) and 283F. A centrifugal pump will be used to increase the pressure of the stream sufficiently to overcome the pressure drop due to friction in each of the components of the process (see the additional information given below). Following the pump, the stream will pass through a heat exchanger where the temperature will be increased from 283F to 500F using steam. The hot pressurized stream will then be fed into a well-mixed isothermal reactor (maintained with a steam jacket around the reactor) where 70% of the mx will be reacted to form 0x and px. The product stream from the reactor is cooled as much as possible with cooling water (100F) in another heat exchanger before entering the separation system. The separation system will yield four streams with the following mass fractions and which are all the same temperature. 1) Assume that the separation system is isothermal (operates at constant temperature) 2) The separation system at the end of the process uses a complex scheme of multiple stages. For this preliminary design, simply represent the separation system by a box labeled "separation system" in your excel sheet 3) Assume countercurrent, single pass heat exchangers 4) mxylenescpTh=msteamH vap 5) The heat capacity for the xylene stream has the formula a. CP(LomolFBTU)=41.7LbmolFBTU+0.153LbmolF2BTUT(F) i, a=41.7 ii. b=0.153 iii. Use Temperature in Fahrenheit not kelvin 6) The density of xylenes is given by the equation A=49.9367;B=0.216174;C=619.996;D=0.23776(m3kg)=B1+(1cT)0A0.216174(1+(1619.996T(K))0.0376 7) Saturated steam is available at 545F(1000psig) and Hvap=650LtmBTU. When used for the heater and reactor, the amount of steam that is used is only that which is condensed, and the condensate leaves as a saturated liquid. 8) Cooling water is available at 90F and has a maximum outlet temperature of 120F. The heat capacity of water is 1gCCal or 4.18gC1 or 1EFBTU 9) In selecting the temperature of the process stream leaving the cooler, observe the rule of them that the minimum temperature difference (either T1 or T2 ) for a heat exchanger is 10F, which means the Temp exciting the Xylene stream will be 100F 10) The pressure drop due to friction in each of the units is estimated to be as follows: The outlet pressure from the separation system is atmospheric pressure. For this preliminary design, the pressure drops in the pipes between the major components may be neglected. The The outhot pressure from the separation system is atmongheric pressure. For this preliminary design, the pressure drops in the pipes between the major components may be neglected. The : pipes are all the same diameter and there are no significtnt changes in elevation The pump has an effidency of 75%(m ( 0.75) Assignment 1) Siketch the process on a blank theet of paper [105] a. The purpose of this is for you to understand the process better and for you to be able to perform the mass balances. Please take a photo or scan this and upload it with your final asighment 2) Perfocm a mass batance on the process, one unit at a time to determine the flows of each type of xylene and the bensene in the process (15.G) a. I would recoenmend that you do these by hand at first befoce your enter them into encel. 3) Put the mars balance in excel so that if one value changes the entire process automatically updates. Hint: the cells need to be linked and functions of one another (Part of 20x see note below] 4) Determine the enthalpy of heating up the xylene stream (before the reactor) and coolirg down the zylene stream (after the reacter). Copy the enthalpy worksheet you made for HW-4(15\%) a. U=xmameCp(T)dT b. The first heat exchangcr takes the stream from the distiliation column at 283 to 500NF C. The second heat eachanger (or the coolet) cools the hot stieam from the reactor from 500%F to 100F d. Will need to make two "enthalpy" sections on your workbook 5) Write an excel function for the dencity of xylene frons 300K to 600K in a new sheet in the workbook Create a graph where density is on the y axis and temperature is on the x axis a. Need to make sure you follow the rules of making a good graph, Include axis labels, tick marks, etc. b. I would make a separate column for KeMin temperatures and Fahrenheit Temperatures 1. To comvert trom Fahrenheit to Kelvin (T)K=5/9[(T)F+459.67] 6) Determine how much cooling water is needed (5\%) a. A=mCparzoATCooling b. You know Aff from the integral above fthis is for the euchanger or "cooler" after the reactorl, you know what Delta T should be, Craj=4.189.1 c. meosing =cMN 7) Determine haw much steam is needed (5W) a. H=mAyap b. You know / from the integral above fyou should have done it twice, this is for the exchanger before the reactor, heatigg up to 500 ) you know AHwop you are solving for the mass flow rate of steam, 50m iteam =ANrepu 8) Calculate how much steam is needed to keep the reactor at 500 F. (5\%) a. Hrem=295ginskef=-rmertedcal=miteunHrop b. Determine how many moles of mx are reacted to calculate Hrxt Total then divide by Hvap to determine mass of steam. Hint: 1BTU=252.2 calories 9) Calculate the volume of the reactor in meters cubed (m3)(10%) Volume=rAFA0X=kFA0(1X)FAOX=k(1X)X You will get units of min, need to divide by the volumetric flow rate (use the density for 500F(533K) of the X ylene Stream). Volumetric flow rate = mass flow rate X density Volume=Volume=k(1X)500Xmxylreactor X=70% (Link this up to the conversion rate cell in your excel workbook, mass flow rate of the xylenes into the reactor) 10) Calculate the size of the pump that is needed. (5\%) a. Add up all the pressure drops listed in the table in the technical details section b. WP=pPm Use density in kg/m3 and mass flow rate in kg/s i. (remember 1kg=2.2lbs ) c. Units will come out to Watts (Joules/second)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts