Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please help with a, b, and c question 2 For reference has all info needed it is cropped properly as it contains all needed info

please help with a, b, and c

question 2 For reference

has all info needed

it is cropped properly as it contains all needed info

assign the problem to someone else if you are confused or refund it

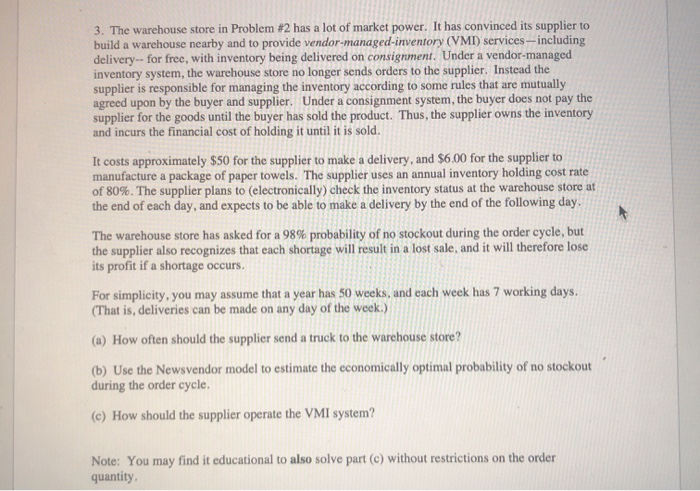

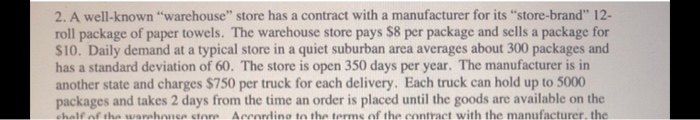

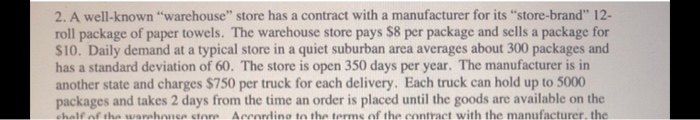

3. The warehouse store in Problem #2 has a lot of market power. It has convinced its supplier to build a warehouse nearby and to provide vendor-managed-inventory (VMI) services - including delivery -- for free, with inventory being delivered on consignment. Under a vendor-managed inventory system, the warehouse store no longer sends orders to the supplier. Instead the supplier is responsible for managing the inventory according to some rules that are mutually agreed upon by the buyer and supplier. Under a consignment system, the buyer does not pay the supplier for the goods until the buyer has sold the product. Thus, the supplier owns the inventory and incurs the financial cost of holding it until it is sold. It costs approximately $50 for the supplier to make a delivery, and $6.00 for the supplier to manufacture a package of paper towels. The supplier uses an annual inventory holding cost rate of 80%. The supplier plans to (electronically) check the inventory status at the warehouse store at the end of each day, and expects to be able to make a delivery by the end of the following day. The warehouse store has asked for a 98% probability of no stockout during the order cycle, but the supplier also recognizes that each shortage will result in a lost sale, and it will therefore lose its profit if a shortage occurs. For simplicity, you may assume that a year has 50 weeks, and each week has 7 working days. (That is, deliveries can be made on any day of the week.) (a) How often should the supplier send a truck to the warehouse store? (b) Use the Newsvendor model to estimate the economically optimal probability of no stockout during the order cycle. (e) How should the supplier operate the VMI system? Note: You may find it educational to also solve part (c) without restrictions on the order quantity 2. A well-known "warehouse" store has a contract with a manufacturer for its store-brand" 12- roll package of paper towels. The warehouse store pays $8 per package and sells a package for $10. Daily demand at a typical store in a quiet suburban area averages about 300 packages and has a standard deviation of 60. The store is open 350 days per year. The manufacturer is in another state and charges $750 per truck for each delivery. Each truck can hold up to 5000 packages and takes 2 days from the time an order is placed until the goods are available on the According to the terms of the contract with the manufacturer, the ehalf of the war honeston 3. The warehouse store in Problem #2 has a lot of market power. It has convinced its supplier to build a warehouse nearby and to provide vendor-managed-inventory (VMI) services - including delivery -- for free, with inventory being delivered on consignment. Under a vendor-managed inventory system, the warehouse store no longer sends orders to the supplier. Instead the supplier is responsible for managing the inventory according to some rules that are mutually agreed upon by the buyer and supplier. Under a consignment system, the buyer does not pay the supplier for the goods until the buyer has sold the product. Thus, the supplier owns the inventory and incurs the financial cost of holding it until it is sold. It costs approximately $50 for the supplier to make a delivery, and $6.00 for the supplier to manufacture a package of paper towels. The supplier uses an annual inventory holding cost rate of 80%. The supplier plans to (electronically) check the inventory status at the warehouse store at the end of each day, and expects to be able to make a delivery by the end of the following day. The warehouse store has asked for a 98% probability of no stockout during the order cycle, but the supplier also recognizes that each shortage will result in a lost sale, and it will therefore lose its profit if a shortage occurs. For simplicity, you may assume that a year has 50 weeks, and each week has 7 working days. (That is, deliveries can be made on any day of the week.) (a) How often should the supplier send a truck to the warehouse store? (b) Use the Newsvendor model to estimate the economically optimal probability of no stockout during the order cycle. (e) How should the supplier operate the VMI system? Note: You may find it educational to also solve part (c) without restrictions on the order quantity 2. A well-known "warehouse" store has a contract with a manufacturer for its store-brand" 12- roll package of paper towels. The warehouse store pays $8 per package and sells a package for $10. Daily demand at a typical store in a quiet suburban area averages about 300 packages and has a standard deviation of 60. The store is open 350 days per year. The manufacturer is in another state and charges $750 per truck for each delivery. Each truck can hold up to 5000 packages and takes 2 days from the time an order is placed until the goods are available on the According to the terms of the contract with the manufacturer, the ehalf of the war honeston Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started