Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please i want the answer with the assumption. Plasma spray-coating processes are often used to provide surface protection for materials exposed to harsh environments, which

please i want the answer with the assumption.

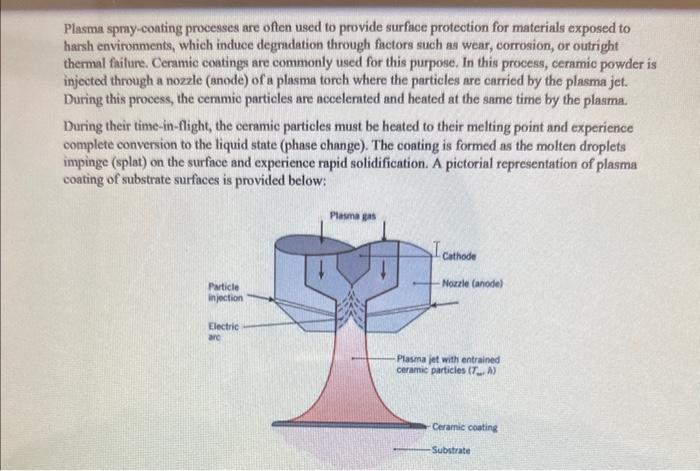

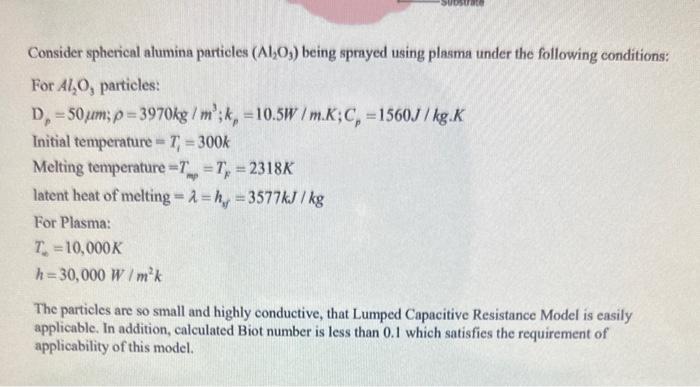

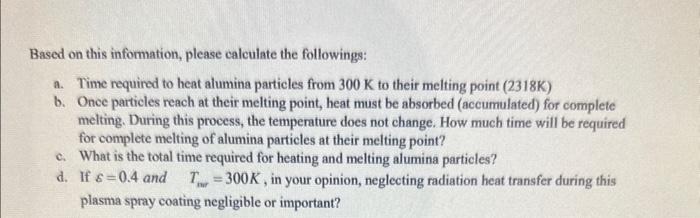

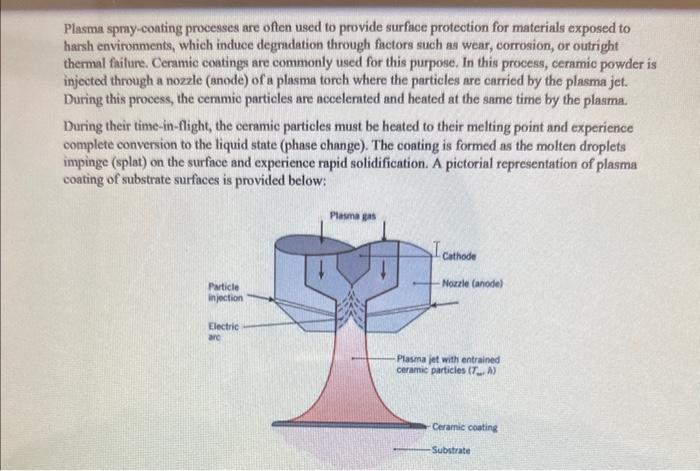

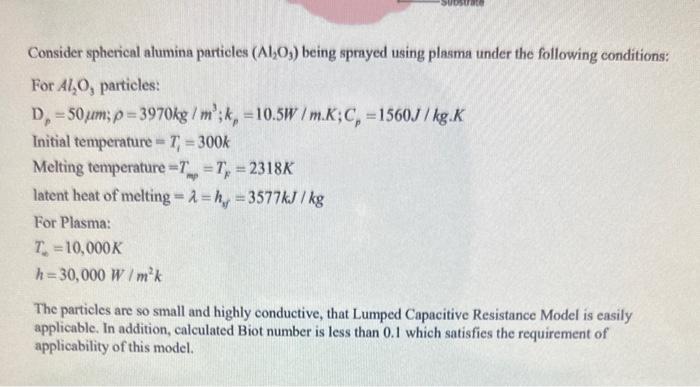

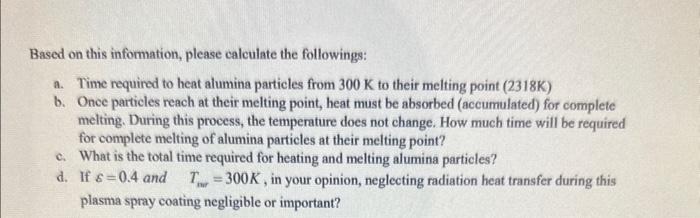

Plasma spray-coating processes are often used to provide surface protection for materials exposed to harsh environments, which induce degradation through factors such as wear, corrosion, or outright thermal failure. Ceramic contings are commonly used for this purpose. In this process, ceramic powder is injected through a nozzle (anode) of a plasma torch where the particles are carried by the plasma jet. During this process, the cemmic particles are accelerated and heated at the same time by the plasma. During their time-in-flight, the ceramic particles must be heated to their melting point and experience complete conversion to the liquid state (phase change). The coating is formed as the molten droplets impinge (splat) on the surface and experience rapid solidification. A pictorial representation of plasma coating of substrate surfaces is provided below: Consider spherical alumina particles (Al2O3) being sprayed using plasma under the following conditions: For Al2O3 particles: Dp=50m;=3970kg/m3;kp=10.5W/mK;Cp=1560J/kgKInitialtemperature=Ti=300kMeltingtemperature=Tmp=TF=2318Klatentheatofmelting==hf=3577kJ/kgForPlasma:Tw=10,000Kh=30,000W/m2k The particles are so small and highly conductive, that Lumped Capacitive Resistance Model is easily applicable. In addition, calculated Biot number is less than 0.1 which satisfies the requirement of applicability of this model. Based on this information, please calculate the followings: a. Time required to heat alumina particles from 300K to their melting point (2318K) b. Once particles reach at their melting point, heat must be absorbed (accumulated) for complete melting. During this process, the temperature does not change. How much time will be required for complete melting of alumina particles at their melting point? c. What is the total time required for heating and melting alumina particles? d. If =0.4 and Tmer=300K, in your opinion, neglecting radiation heat transfer during this plasma spray coating negligible or important

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started