Answered step by step

Verified Expert Solution

Question

1 Approved Answer

PLEASE ONLY ANSWER QUESTION 4, (PART A) TO (PART E) Before answering parts a) to e) of that question, write down the mathematical model for

PLEASE ONLY ANSWER QUESTION 4, (PART A) TO (PART E)

Before answering parts a) to e) of that question, write down the mathematical model for the generic problem and identify what the decision variables and the parameters are. In responding to the parts, include a snapshot (print screen) of the optimality results from Excel Solver.

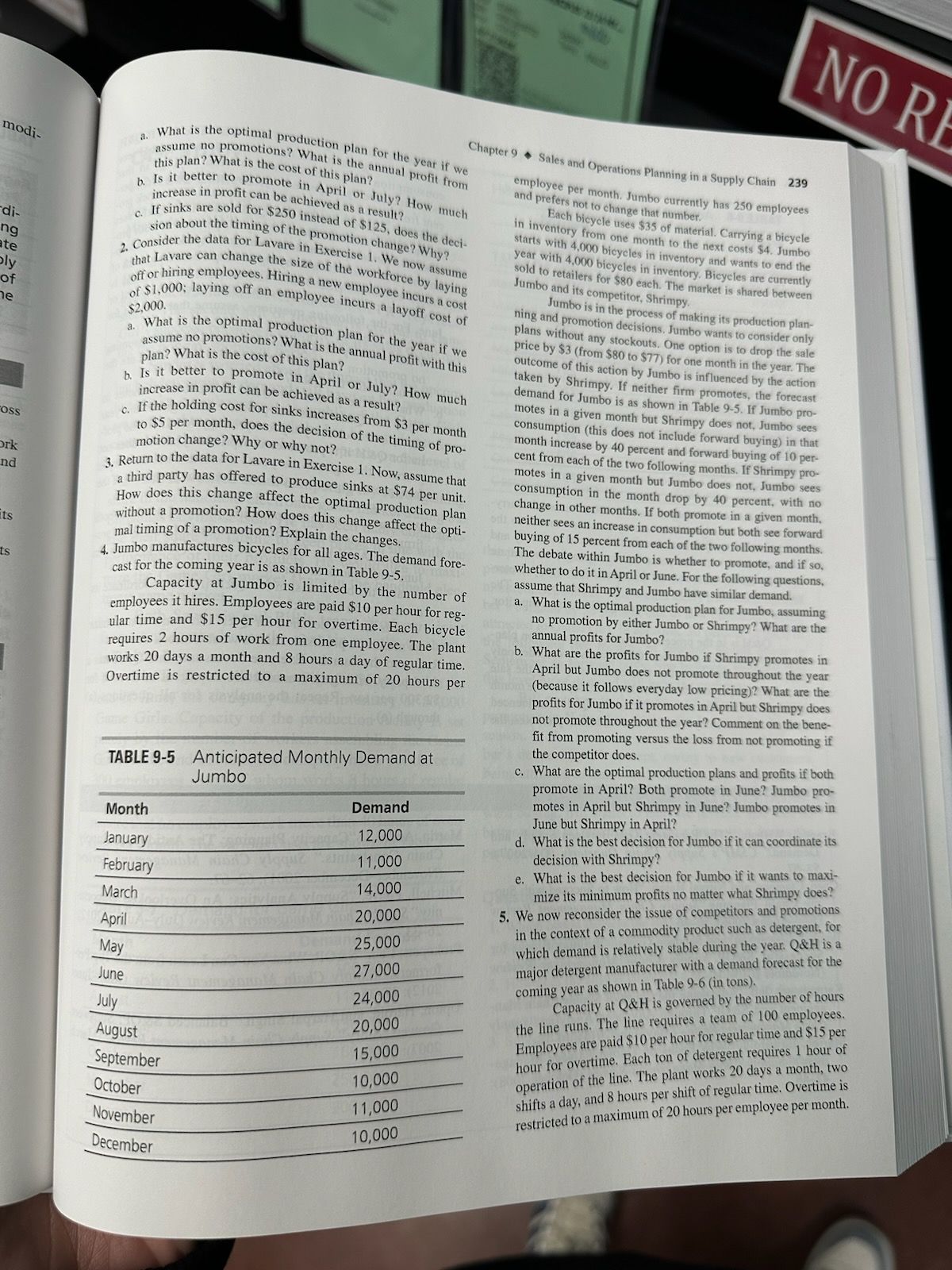

a. What is the optimal production plan for the year if wepter 9 assume no promotions? What is the annuat year if we this plan? What is the cost of this plan? b. Is it better to promote in April or July? How much increase in profit can be achieved as a result? c. If sinks are sold for $250 instead of $125, does the decision about the timing of the promotion change? Why? 2. Consider the data for Lavare in Exercise 1. We now assume that Lavare can change the size of off or hiring employees. Hirize of the workforce by laying of $1,000; laying off an eng a new employee incurs a cost $2,000. employee per month. Jumbo currently has 250 employees and prefers not to change that number. Each bicycle uses $35 of material. Carrying a bicycle in inventory from one month to the next costs $4. Jumbo starts with 4,000 bicycles in inventory and wants to end the year with 4,000 bicycles in inventory. Bicycles are currently sold to retailers for $80 each. The market is shared between Jumbo and its competitor, Shrimpy. Jumbo is in the process of making its production planassume no promotions? What is for the year if we plan? What is the cost of this profit with this b. Is it better to promote in April or July? How much increase in profit can be achieved as a result? c. If the holding cost for sinks increases from $3 per month to $5 per month, does the decision of the timing of promotion change? Why or why not? plans without any stockouts. One option is to drop the sale price by $3 (from $80 to $77 ) for one month in the year. The outcome of this action by Jumbo is influenced by the action taken by Shrimpy. If neither firm promotes, the forecast demand for Jumbo is as shown in Table 9-5. If Jumbo promotes in a given month but Shrimpy does not, Jumbo sees consumption (this does not include forward buying) in that month increase by 40 percent-and forward buying of 10 permotes in a given month but Jumbo does not, Jumbo sees consumption in the month drop by 40 percent, with no change in other months. If both promote in a given month. neither sees an increase in consumption but both see forward buying of 15 percent from each of the two following months. The debate within Jumbo is whether to promote, and if so, whether to do it in April or June. For the following questions, assume that Shrimpy and Jumbo have similar demand. a. What is the optimal production plan for Jumbo, assuming no promotion by either Jumbo or Shrimpy? What are the annual profits for Jumbo? b. What are the profits for Jumbo if Shrimpy promotes in April but Jumbo does not promote throughout the year (because it follows everyday low pricing)? What are the profits for Jumbo if it promotes in April but Shrimpy does not promote throughout the year? Comment on the benefit from promoting versus the loss from not promoting if the competitor does. c. What are the optimal production plans and profits if both promote in April? Both promote in June? Jumbo promotes in April but Shrimpy in June? Jumbo promotes in June but Shrimpy in April? d. What is the best decision for Jumbo if it can coordinate its decision with Shrimpy? e. What is the best decision for Jumbo if it wants to maximize its minimum profits no matter what Shrimpy does? 5. We now reconsider the issue of competitors and promotions in the context of a commodity product such as detergent, for which demand is relatively stable during the year. Q\&H is a major detergent manufacturer with a demand forecast for the coming year as shown in Table 9-6 (in tons). Capacity at Q\&H is governed by the number of hours the line runs. The line requires a team of 100 employees. Employees are paid $10 per hour for regular time and $15 per hour for overtime. Each ton of detergent requires 1 hour of operation of the line. The plant works 20 days a month, two shifts a day, and 8 hours per shift of regular time. Overtime is restricted to a maximum of 20 hours per employee per month

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started