Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please provide solution of all parts Course name: Project management Probably the most well documented problem of this then July 2001 tower opening was delayed

Please provide solution of all parts

Course name: Project management

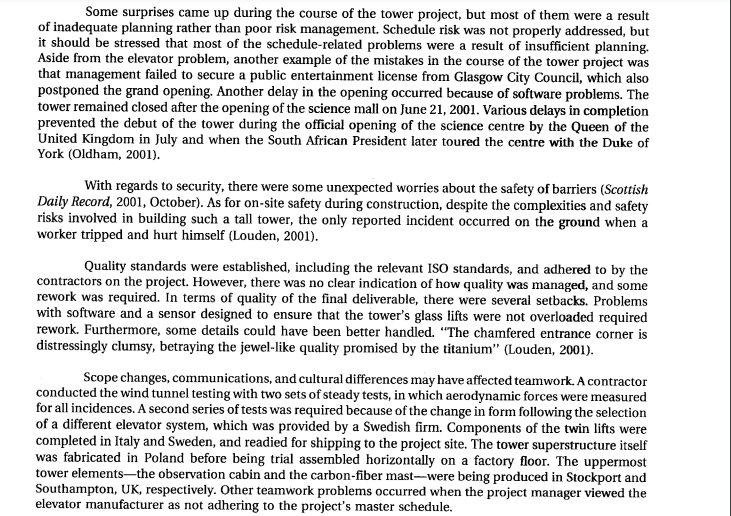

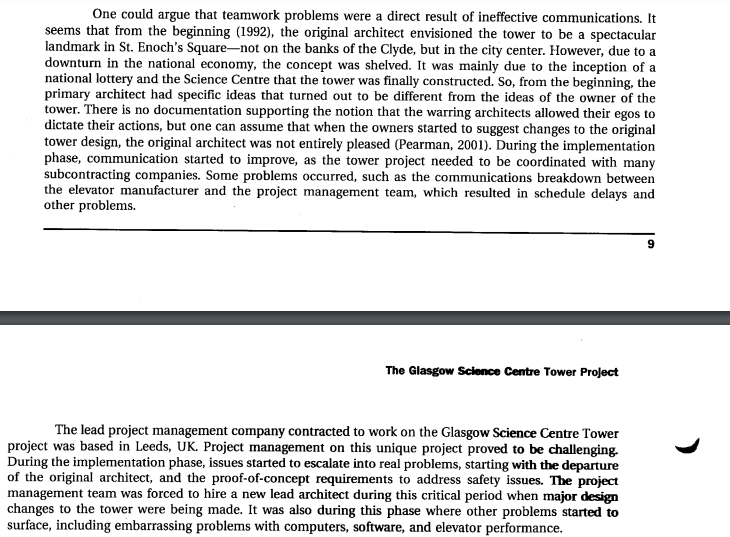

Probably the most well documented problem of this then July 2001 tower opening was delayed because it was discovered that the tower's ans were too heavy. Managers were furious and started examining penalty clauses in their contract a smedish elevator manufacturer. According July). This resulted in another three-week detay. 8 The Glasgow Science Centre Tower Project The elevator manufacturer had a distinguished record with regards to unique situations on the international level. The company participated in the restoration of the Eiffel Tower in Paris, France, in the construction of the Channel Tunnel (Chunnel), in the renovation of the Statute of Liberty in New York City, USA, in 1984, and in the renovation of the Washington Monument in Washington, DC, USA, in 2000. It is possible that cultural differences, such as holiday schedules and the degree of flexibility associated with them, may not have been factored into the master schedule. It is also possible that project manager(s) did not ensure that all project participants reviewed and committed to that master schedule. Rating Scale: 5-Excellent, 4-Very Good, 3-Good, 2-Poor, 1-Very Poor 2. Please highlight the major areas of strength in the management of this phase of the project: 3. Please highlight the major opportunities for improvement in the management of this phase of the project: One could argue that teamwork problems were a direct result of ineffective communications. It seems that from the beginning (1992), the original architect envisioned the tower to be a spectacular landmark in St. Enoch's Square-not on the banks of the Clyde, but in the city center. However, due to a downturn in the national economy, the concept was shelved. It was mainly due to the inception of a national lottery and the Science Centre that the tower was finally constructed. So, from the beginning, the primary architect had specific ideas that turned out to be different from the ideas of the owner of the tower. There is no documentation supporting the notion that the warring architects allowed their egos to dictate their actions, but one can assume that when the owners started to suggest changes to the original tower design, the original architect was not entirely pleased (Pearman, 2001). During the implementation phase, communication started to improve, as the tower project needed to be coordinated with many subcontracting companies. Some problems occurred, such as the communications breakdown between the elevator manufacturer and the project management team, which resulted in schedule delays and other problems. 9 The Glasgow Sclence Centre Tower Project The lead project management company contracted to work on the Glasgow Science Centre Tower project was based in Leeds, UK. Project management on this unique project proved to be challenging. During the implementation phase, issues started to escalate into real problems, starting with the departure of the original architect, and the proof-of-concept requirements to address safety issues. The project management team was forced to hire a new lead architect during this critical period when major design changes to the tower were being made. It was also during this phase where other problems started to surface, including embarrassing problems with computers, software, and elevator performance. By early 1999 , just as construction of the tower base was getting started, the project was determined to be over budget and put on hold while the owners considered cancellation. Additional wind tunnel tests were conducted to determine how much structural steel could be eliminated (Reina, 1999). The original architectural firm and the structural contractors reduced the number of trusses required (Civil Engineering. 1999). The Glasgow Science Centre insisted that the tower be "engineered down to budget," despite the fact that they also demanded extra exhibition space (Reina, 1999; Gadher, 1999). This 14\% reduction demand also required changes to the cabin and mast, and caused the open rift between the Science Centre project team and the architectural firm, which felt that safety had been compromised. Further, the Science Centre project team felt that the beauty and quality of its design had been sacrificed for the sake of the exhibition hall. The architectural firm continued to claim it still was owed money from the Science Centre. The Centre's counterclaim was that the exhibition hall work was part of the original design and that in acted responsibly in managing public funding (Gadher, 1999; Dennis, 2001). The cost overnun required scope adjustments and, ultimately, caused implementation delays. The cost and scope change issues brought the project to a halt in 1999. At that time, construction only on the tower base was in progress (Reina, 2001). Construction on the tower began in March of 2002 with a scheduled April 2001 completion as the opening date (Denholm, 2000; Reina 1999). Actual tower construction proceeded quickly, and the construction work dismantled and shipped to Glasgow (CITB ConstructionSkills, 2003). However, a series of pos tases A final opening date was determined for June 2001 claim that the tower would open "in two weeks" (Wade, 2001). Despite some miscommunications and the need for some have a clear understanding of the concept of the tower project, perforined os and fulfilled building, fire, and security systems for the entire Glasgow Science Cenes selecting a single vendor, the tower project benefited from having a singer at all phases of the project, from planning to installation through training and mos completed using the appropriate ISO standards. The original scope of the tower included a pod-shaped, glass viewing cabin topped by a 130ft. (39.62m) steel mast. It was subsequently determined that that the glass pod would become uncomfortably hot in the sun and would be difficult to clean. The steel mast was declared too tall and heavy for the tower. The final design for the cabin was a metal composite with a slit-like viewing window. The mast was reduced to 82ft. (24.99m) and constructed of a carbon-fiber material (Dennis, 2001). The exhibition area at the base was expanded by an extra 1,600 square feet (148.64m2). Additionally, the horizontal bearing mechanism was moved from the underground container to near the public elevator entrances (Gadher, 1999; Reina, 2001). 7 These changes resulted in conflicts between the owner of the Glasgow Science Centre and its architects. The architectural firm's objections to the multiple changes to its design erupted into a public feud and ultimately the firm was removed from the project and replaced by another architectural firm (Reina, 2001). The original firm publicly stated that the tower was, at best, dreadful and, at worst, unsafe (Dennis, 2001; Gadher, 1999). Indeed, the changes made to the elevator design resulted in a major problem that kept the tower closed to the public for an extended period of time. The elevators appeared to be too heavy for the mechanisms that ran them. Construction was slow getting off the mark, but, once under way, it seemed to proceed quickly. Unfortunately, it appears that some of the scope changes resulted in major delays in the completion of the tower. Some surprises came up during the course of the tower project, but most of them were a result of inadequate planning rather than poor risk management. Schedule risk was not properly addressed, but it should be stressed that most of the schedule-related problems were a result of insufficient planning. Aside from the elevator problem, another example of the mistakes in the course of the tower project was that management failed to secure a public entertainment license from Glasgow City Council, which also postponed the grand opening. Another delay in the opening occurred because of software problems. The tower remained closed after the opening of the science mall on June 21,2001 . Various delays in completion prevented the debut of the tower during the official opening of the science centre by the Queen of the United Kingdom in July and when the South African President later toured the centre with the Duke of York (Oldham, 2001). With regards to security, there were some unexpected worries about the safety of barriers (Scottish Daily Record, 2001, October). As for on-site safety during construction, despite the complexities and safety risks involved in building such a tall tower, the only reported incident occurred on the ground when a worker tripped and hurt himself (Louden, 2001). Quality standards were established, including the relevant ISO standards, and adhered to by the contractors on the project. However, there was no clear indication of how quality was managed, and some rework was required. In terms of quality of the final deliverable, there were several setbacks. Problems with software and a sensor designed to ensure that the tower's glass lifts were not overloaded required rework. Furthermore, some details could have been better handled. "The chamfered entrance corner is distressingly clumsy, betraying the jewel-like quality promised by the titanium" (Louden, 2001). Scope changes, communications, and cultural differences may have affected teamwork. A contractor conducted the wind tunnel testing with two sets of steady tests, in which aerodynamic forces were measured for all incidences. A second series of tests was required because of the change in form following the selection of a different elevator system, which was provided by a Swedish firm. Components of the twin lifts were completed in Italy and Sweden, and readied for shipping to the project site. The tower superstructure itself was fabricated in Poland before being trial assembled horizontally on a factory floor. The uppermost tower elements-the observation cabin and the carbon-fiber mast-were being produced in Stockport and Southampton, UK, respectively. Other teamwork problems occurred when the project manager viewed the elevator manufacturer as not adhering to the project's master scheduleStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started