Answered step by step

Verified Expert Solution

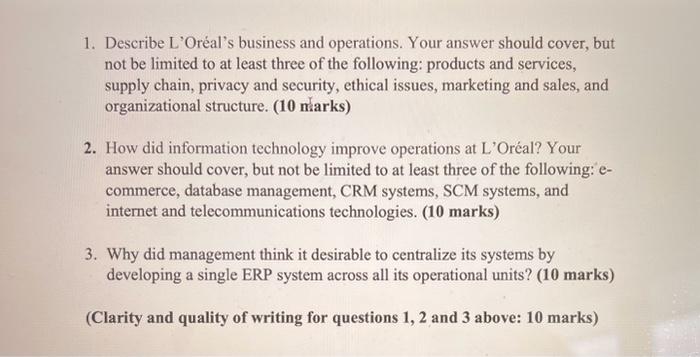

Question

1 Approved Answer

Please read case and answer the questions L'Oral Group is the world's largest cosmetics and beauty company, and it is a truly global brand. Virtually

Please read case and answer the questions

L'Oral Group is the world's largest cosmetics and beauty company, and it is a truly global brand. Virtually everyone has heard of this company or used its products, with world-name brands including L'Oral Paris and Maybelline (massmarket), Lancme (luxury), Redken and SoftSheen-Carson (retail and salon), and The Body Shop natural cosmetics. Altogether L'Oral has more than 28 global brands in 130 countries and more than 77,000 employees. This is a very challenging company to manage worldwide. Each of L'Oral's 40 manufacturing sites deals with hundreds or even thousands of different recipes for L'Oral products. Every recipe must be followed exactly, and every ingredient must be tested for quality. This level of complexity increases the chances of human error and waste. L'Oral's management believed the company needed to do more to ensure that its products are all manufactured worldwide under uniform production and quality standards. L'Oral's various operating units in different regions and countries were running their own versions of SAP enterprise resource planning (ERP) systems. In order to achieve the goal of global product uniformity, these disparate systems had to be standardized and consolidated. It was hoped that productivity, quality, and safety would be improved by standardizing best-practice processes throughout the Management knew that this level of organizational change required changes in employee behavior, and it dedicated significant resources to change management and promoting knowledge-sharing across geographical and cultural boundaries. The company assigned a business "oivner" for each core business process who would help analyze the processes at each site and implement the necessary changes. L'Oral's information systems team would then create the system design and implementation plan for the solution. L'Oral was able to implement a single global instance of SAP's ERP system and integrate that with Apriso's FlexNet for operations management using a core model that is replicated at each site. FlexNet is a unified suite of manufacturing software applications for coordinating all manufacturing operations - within the plant, between plants, and across a company's supply chain and enterprise. L'Oral named its new system ISIS, standing for Integrated Solution for Industrial Systems. L'Oral's transactional processes, financial controls, and purchasing are all integrated into the FlexNet manufacturing operations system on the shop floor run. L'Oral runs ISIS at its central data center in Montpellier, France, where it keeps the master data for the business. FlexNet runs on servers in individual factories so that operations can continue if there is a problem with L'Oral's main ISIS guides factory operators through each recipe for a product and automatically records the weight of each ingredient to ensure exact quantities are being used. All ingredients are tested, and raw materials that have passed tests for quality are given labels that must be scanned by the worker before being added to the recipe. In the I -12 - past, shop workers used to rummage around for information on recipes or raw materials. The labels also provide forklift drivers with directions on which materials need to be taken to the packaging station. With this level of centralization and global processes, L'Oral is able to implement new processes and related systems changes globally much more rapidly than in the past. For example, when the company had multiple versions of SAP running in different operating units, it could take two to five years for the entire company to upgrade to the latest version of the software. With its global enterprise-wide version of SAP and FlexNet, a recent L'Oral's upgrade took just one weekend. factories, and bring new factories on board much more quickly. For example, a recently acquired Y ves St. Laurent factory was integrated with L'Oral's global quality assurance, safety, and efficiency practices within a few months. However, there is still some flexibility in the system to tailor some processes to local needs if necessary. L'Oral management believes the company's overall capacity has increased and that the workplace is more productive and efficient. Shop workers have asserted that the system is easy to use and has reduced confusion and stress. Fewer materials are wasted, there are fewer discrepancies between actual versus planned production, and the company is able to maintain lower, better managed inventories. L'Oral's efforts to create global manufacturing systems identify some of the issues that truly global organizations need to consider if they want to operate worldwide. Like many large, multinational firms, L'Oral has numerous operating units in many different countries. Even though these units were running SAP ERP software, they used their own versions and business processes. As a result, L'Oral was unable to effectively coordinate global manufacturing operations or ensure that its vast array of products met global quality and production standards. units in many different countries. Even though these units were running SAP ERP software, they used their own versions and business processes. As a result, L'Oral was unable to effectively coordinate global manufacturing operations or ensure that its vast array of products met global quality and production standards. To solve its global management and business challenges, L'Oral had all of its business units adopt a standard core version of SAP software and standard manufacturing and production processes. The ERP system was integrated with the FlexNet manufacturing software suite to coordinate manufacturing operations on a global scale. Management realized that this level of organizational change required careful attention to change management. Although L'Oral now has standard global manufacturing and production systems and business processes, it is sensitive to local differences and gives units some leeway to tailor processes to local needs. 1. Describe L'Oral's business and operations. Your answer should cover, but not be limited to at least three of the following: products and services, supply chain, privacy and security, ethical issues, marketing and sales, and organizational structure. (10 marks) 2. How did information technology improve operations at L'Oral? Your answer should cover, but not be limited to at least three of the following: ecommerce, database management, CRM systems, SCM systems, and internet and telecommunications technologies. (10 marks) 3. Why did management think it desirable to centralize its systems by developing a single ERP system across all its operational units? (10 marks) (Clarity and quality of writing for questions 1,2 and 3 above: 10 marks)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started