Question

Please show a detailed solution for the problem in the image. Hints and FAQ: Hints As the production control manager, how do I count the

Please show a detailed solution for the problem in the image.

Hints and FAQ:

Hints

As the production control manager, how do I count the amount of inventory that is in-process / on the shop floor? Also, what is the impact of increasing MRP lead time?

Put yourself on the shop floor as a production manager counting the number of parts that you have for a specific material. You would count what you have in stock as completed parts AND you would count the number of parts that you have in-process... that is, how many you are currently making. The key is to count EVERYTHING that you have in-process. Let's say you found a quantity of 20 in stock and three orders that are currently being produced with each being at a different step in the production process (which operations are completed). If the three in-process orders are for quantities of 10,8, and 12... then you would have 30 in-process and 20 in stock... so your total inventory count for that specific part would be 50 (30+20). For our assigned homework problem, you would go through this process for EACH period. The PAB is obvious for each period because it is given. The only tricky thing in this problem is to be sure that you are including all in-process orders. In period three, for example, you have two orders in-process... an order for 50 which was released in period 2 and will be complete in period 4, and another order for 50 which was released in period 3 and will be completed in week 5 (2 week lead time). So your inventory (in-process + stock) = 50 + 50 + 20 = 120; with a WIP inventory value of $12,000 (120*$100). Make this calculation for each period and that is all there is to it. As mentioned, the key is to be sure that you are counting ALL in-process orders for that period. For Part B of the problem, you will calculate the PAB and orders with a new increased lead time of 3. You will then go through the same calculations in Part B and you will see how the WIP inventory levels have greatly increased by increasing the lead time. Conventional thinking by many production control managers is that if you increase the lead time, you give yourself more time to complete the item... but as you see, all it does is release more in-process orders to the shop floor and you need to keep this material somewhere right? So you will have more material sitting all around your facility and thus increasing the queues.

Frequently Asked Questions

Question: I cannot seem to figure out how you determine the number of parts you have in process. Can you assist?

Answer: Let's concentrate on the first part where we are working on Part D when the lead time is 2 weeks.

First, you need to do the usual MRP processing to find the PAB values, i.e., number of items in stock. This step is done for this case already. You should verify that you understand the procedure to find the values in the PAB and Planned Order Releases rows.

Then, the number of units in total WIP are those that are already in stock (PAB) plus those that are in-process as part of a released order.

Looking at it week by week:

Week 1: PAB is 60, and there is no order in process (because there is no planned order release for week 1), so the total WIP inventory is 60.

Week 2: PAB is 60. In week 2, we also planned to start the production of 50 units. The production is assumed to start at the start of the week, meaning that the entire week in week 2 we will be working on those 50 units. The total WIP for week 2 is then the stock quantity in PAB (60) plus the ones that we are working (50), which makes a total of 110 units.

Week 3: PAB is 20. We know that the production we started in week 2 will take 2 weeks in total. We worked on that order only one week so far (during week 2), which means that we will continue with those units in week 3 as well. The total WIP counting the PAB and previously started order is 20+50=70. 20 is the stock quantity in PAB and 50 is the part of the order coming from the previous week. In addition to all of these, a new 50 units of order is planned to be started in week 3. So, we will also be working on this new order. That will then make the total WIP 70+50=120.

And so on...

I find that you can keep track of the inventory better if you prepare a table. The first row will be the weeks, 1-7. Second row is the PAB. Then the third row corresponds to the first planned order of quantity 50: starts in week 2 and lasts 2 weeks during week 2 and week 3. Fourth row corresponds to the second planned order of quantity 50: starts in week 3 and lasts 2 weeks during week 3 and week 4, and so on.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 60 | 60 | 20 | 0 | 0 | 0 | 0 |

| 50 | 50 | |||||

| 50 | 50 |

Then, you can add the numbers under each column to find the total inventory for the corresponding week.

Under week 1, there is only 60, so the total WIP is 60

Under week 2, there is 60 and 50, so the total WIP is 110

Under week 3, there is 20, 50, and 50, so the total WIP is 120, and so on.

Hope this helps.

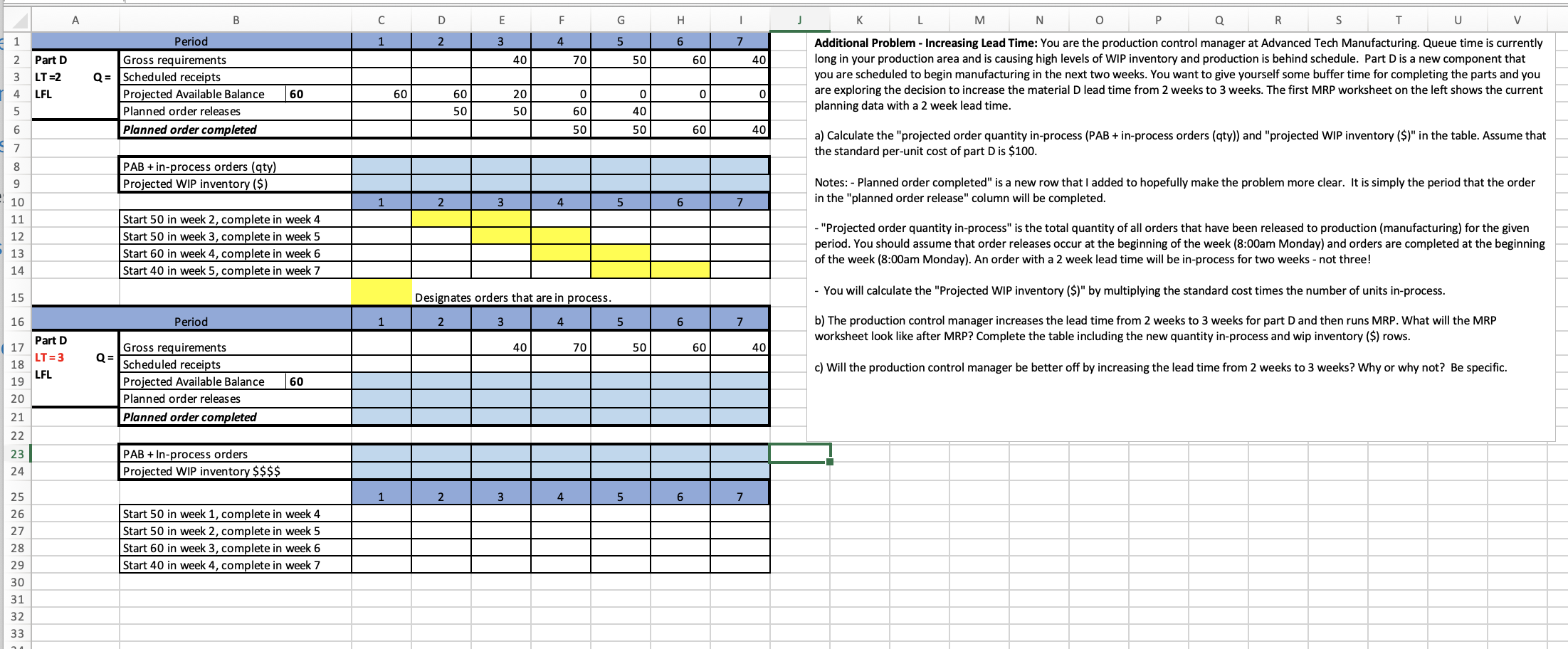

Additional Problem - Increasing Lead Time: You are the production control manager at Advanced Tech Manufacturing. Queue time is currently long in your production area and is causing high levels of WIP inventory and production is behind schedule. Part D is a new component that you are scheduled to begin manufacturing in the next two weeks. You want to give yourself some buffer time for completing the parts and you are exploring the decision to increase the material D lead time from 2 weeks to 3 weeks. The first MRP worksheet on the left shows the current planning data with a 2 week lead time. a) Calculate the "projected order quantity in-process (PAB + in-process orders (qty)) and "projected WIP inventory (\$)" in the table. Assume that the standard per-unit cost of part D is $100. Notes: - Planned order completed" is a new row that I added to hopefully make the problem more clear. It is simply the period that the order in the "planned order release" column will be completed. - "Projected order quantity in-process" is the total quantity of all orders that have been released to production (manufacturing) for the given period. You should assume that order releases occur at the beginning of the week (8:00am Monday) and orders are completed at the beginning of the week (8:00am Monday). An order with a 2 week lead time will be in-process for two weeks - not three! - You will calculate the "Projected WIP inventory (\$)" by multiplying the standard cost times the number of units in-process. b) The production control manager increases the lead time from 2 weeks to 3 weeks for part D and then runs MRP. What will the MRP worksheet look like after MRP? Complete the table including the new quantity in-process and wip inventory (\$) rows. c) Will the production control manager be better off by increasing the lead time from 2 weeks to 3 weeks? Why or why not? Be specific. Additional Problem - Increasing Lead Time: You are the production control manager at Advanced Tech Manufacturing. Queue time is currently long in your production area and is causing high levels of WIP inventory and production is behind schedule. Part D is a new component that you are scheduled to begin manufacturing in the next two weeks. You want to give yourself some buffer time for completing the parts and you are exploring the decision to increase the material D lead time from 2 weeks to 3 weeks. The first MRP worksheet on the left shows the current planning data with a 2 week lead time. a) Calculate the "projected order quantity in-process (PAB + in-process orders (qty)) and "projected WIP inventory (\$)" in the table. Assume that the standard per-unit cost of part D is $100. Notes: - Planned order completed" is a new row that I added to hopefully make the problem more clear. It is simply the period that the order in the "planned order release" column will be completed. - "Projected order quantity in-process" is the total quantity of all orders that have been released to production (manufacturing) for the given period. You should assume that order releases occur at the beginning of the week (8:00am Monday) and orders are completed at the beginning of the week (8:00am Monday). An order with a 2 week lead time will be in-process for two weeks - not three! - You will calculate the "Projected WIP inventory (\$)" by multiplying the standard cost times the number of units in-process. b) The production control manager increases the lead time from 2 weeks to 3 weeks for part D and then runs MRP. What will the MRP worksheet look like after MRP? Complete the table including the new quantity in-process and wip inventory (\$) rows. c) Will the production control manager be better off by increasing the lead time from 2 weeks to 3 weeks? Why or why not? Be specificStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started