Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please show all steps and work the information is in the question, if you cannot understand please pass it on to someone else. similar questions

Please show all steps and work

the information is in the question, if you cannot understand please pass it on to someone else. similar questions have been answered just like this ..

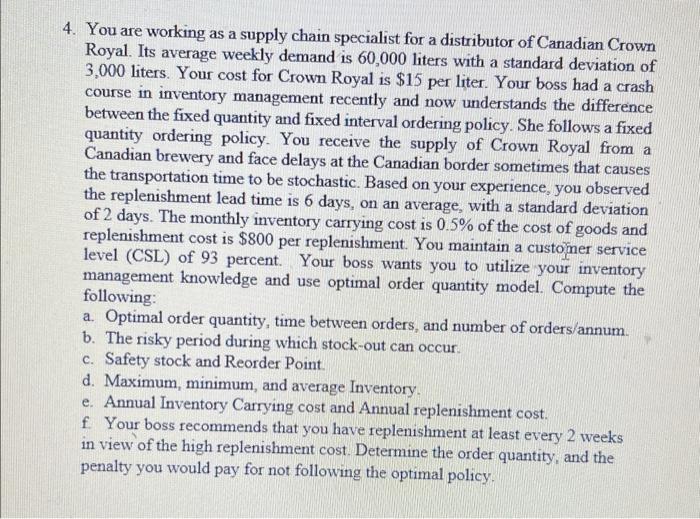

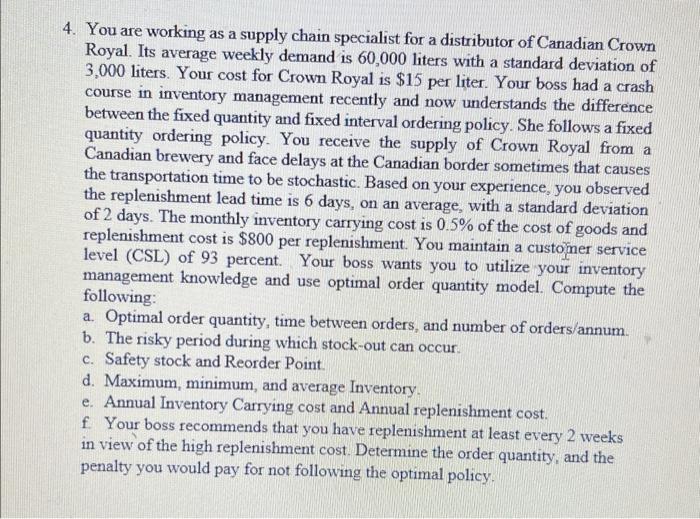

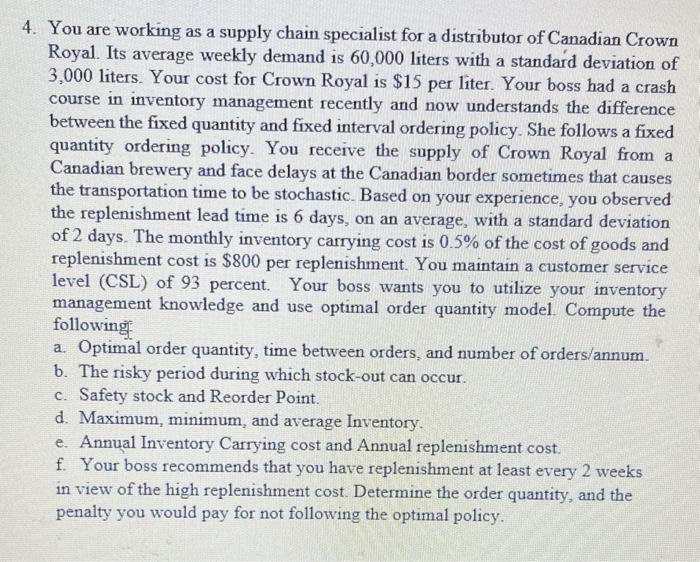

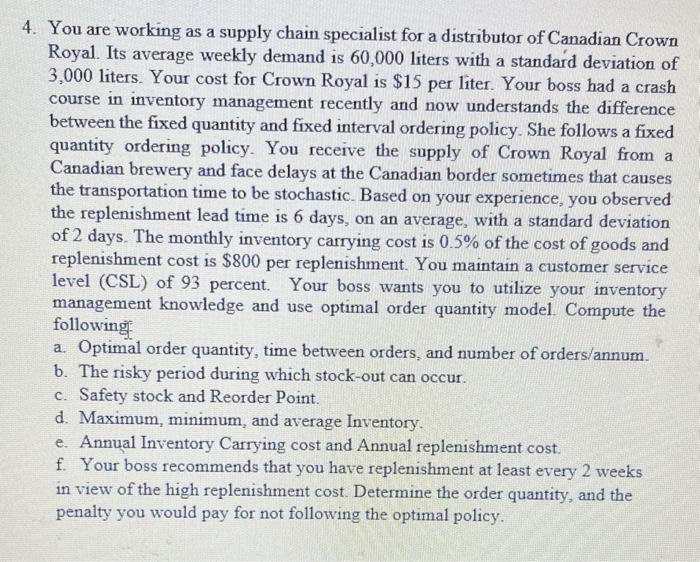

4. You are working as a supply chain specialist for a distributor of Canadian Crown Royal. Its average weekly demand is 60,000 liters with a standard deviation of 3,000 liters. Your cost for Crown Royal is $15 per liter. Your boss had a crash course in inventory management recently and now understands the difference between the fixed quantity and fixed interval ordering policy. She follows a fixed quantity ordering policy. You receive the supply of Crown Royal from a Canadian brewery and face delays at the Canadian border sometimes that causes the transportation time to be stochastic. Based on your experience, you observed the replenishment lead time is 6 days, on an average, with a standard deviation of 2 days. The monthly inventory carrying cost is 0.5% of the cost of goods and replenishment cost is $800 per replenishment. You maintain a custoiner service level (CSL) of 93 percent. Your boss wants you to utilize your inventory management knowledge and use optimal order quantity model. Compute the following: a. Optimal order quantity, time between orders, and number of orders/annum. b. The risky period during which stock-out can occur. c. Safety stock and Reorder Point. d. Maximum, minimum, and average Inventory. e. Annual Inventory Carrying cost and Annual replenishment cost. f. Your boss recommends that you have replenishment at least every 2 weeks in view of the high replenishment cost. Determine the order quantity, and the penalty you would pay for not following the optimal policy. 4. You are working as a supply chain specialist for a distributor of Canadian Crown Royal. Its average weekly demand is 60,000 liters with a standard deviation of 3,000 liters. Your cost for Crown Royal is $15 per liter. Your boss had a crash course in inventory management recently and now understands the difference between the fixed quantity and fixed interval ordering policy. She follows a fixed quantity ordering policy. You receive the supply of Crown Royal from a Canadian brewery and face delays at the Canadian border sometimes that causes the transportation time to be stochastic. Based on your experience, you observed the replenishment lead time is 6 days, on an average, with a standard deviation of 2 days. The monthly inventory carrying cost is 0.5% of the cost of goods and replenishment cost is $800 per replenishment. You maintain a customer service level (CSL) of 93 percent. Your boss wants you to utilize your inventory management knowledge and use optimal order quantity model. Compute the following: a. Optimal order quantity, time between orders, and number of orders/annum. b. The risky period during which stock-out can occur. c. Safety stock and Reorder Point. d. Maximum, minimum, and average Inventory. e. Annual Inventory Carrying cost and Annual replenishment cost. f. Your boss recommends that you have replenishment at least every 2 weeks in view of the high replenishment cost. Determine the order quantity, and the penalty you would pay for not following the optimal policy

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started