Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Please show all work/steps and provide explanations of the answers. The Beerstore packages specialty beers into gift packs and sells them via the Internet. Its

Please show all work/steps and provide explanations of the answers.

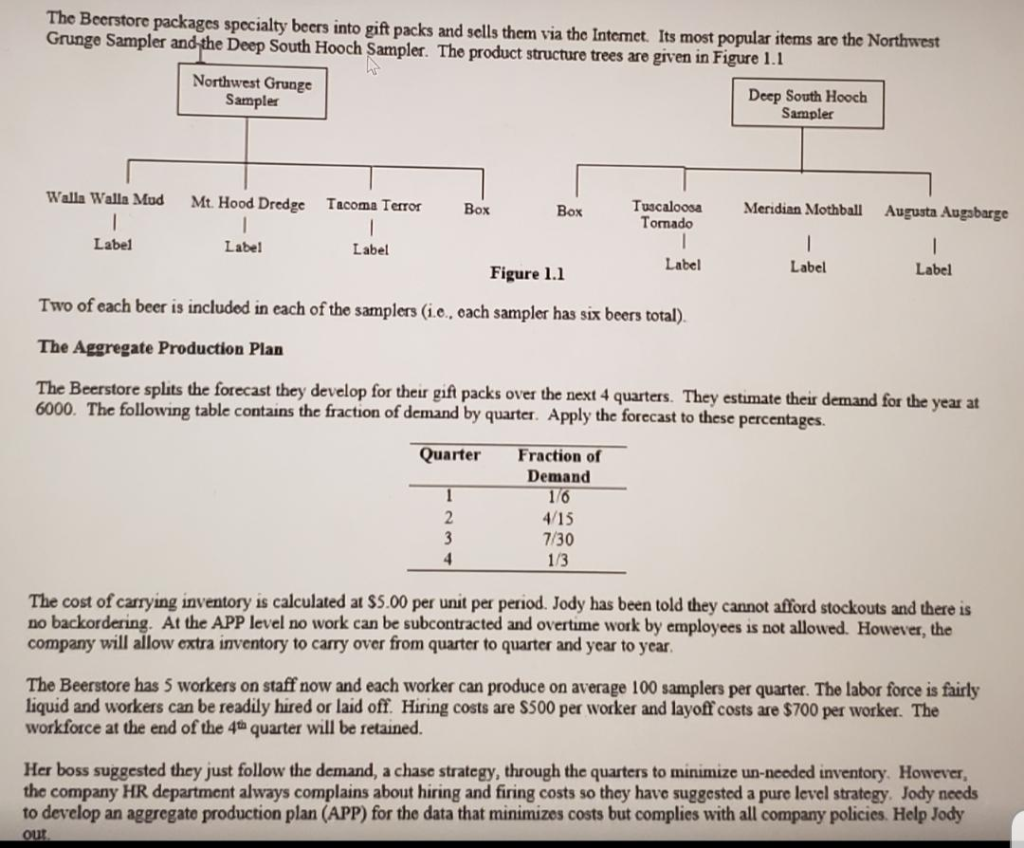

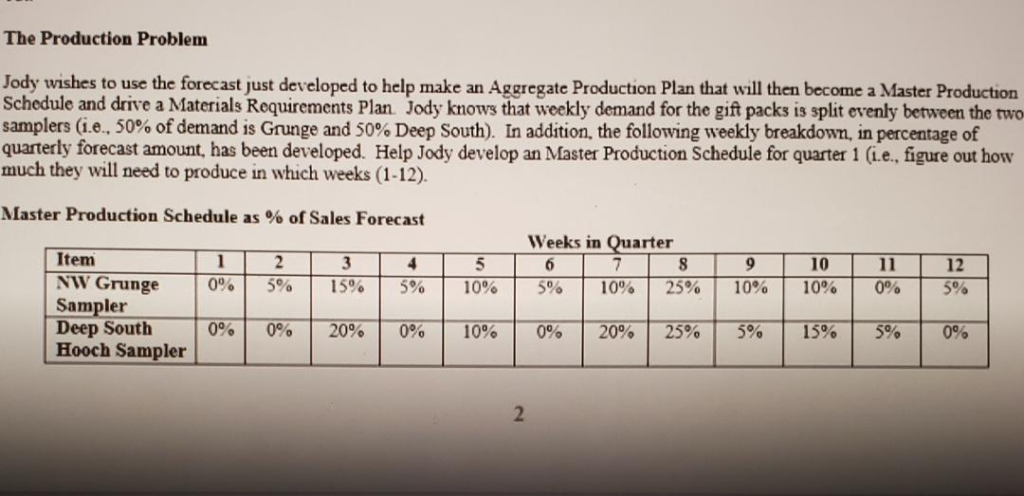

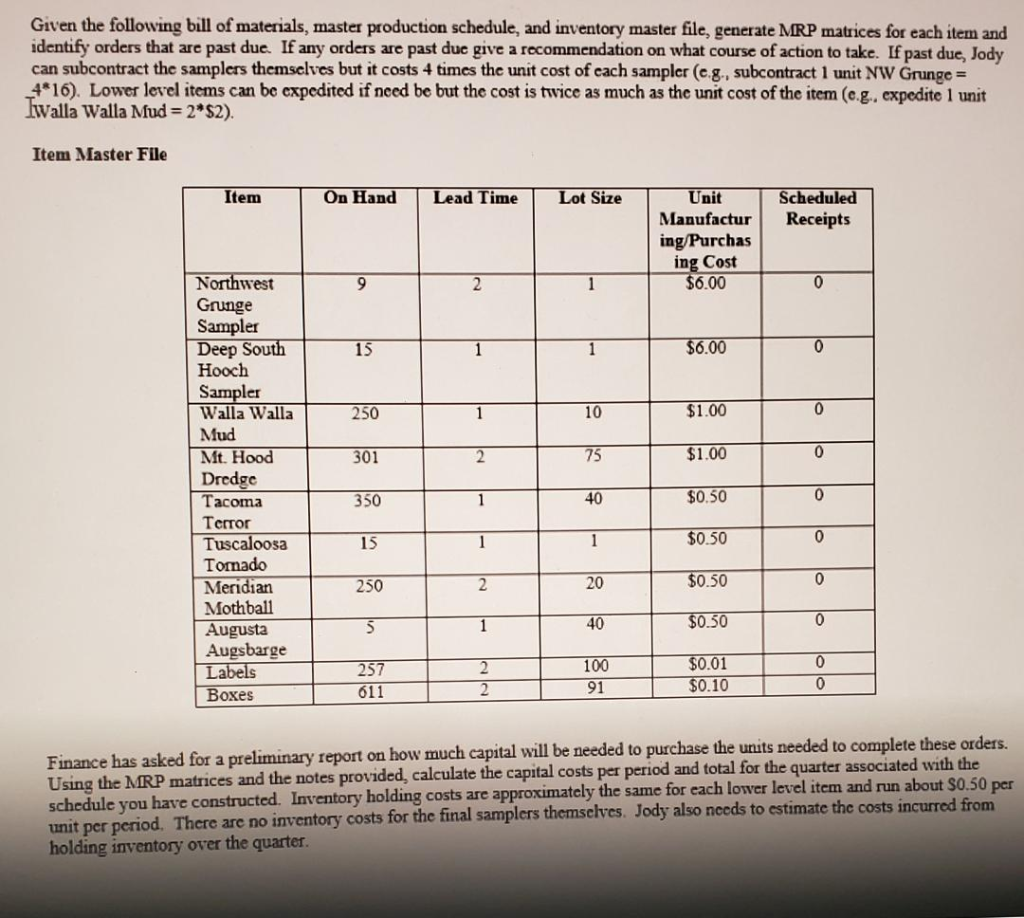

The Beerstore packages specialty beers into gift packs and sells them via the Internet. Its most popular items are the Northwest Grunge Sampler and-the Deep South Hooch Sampler. The product structure trees are given in Figure 1.1 Northwest Grunge Deep South Hooch Sampler Sampler Walla Walla Mud Mt. Hood Dredge Tacoma Terror Tuscaloosa Tomado Meridian Mothball Box Box Augusta Augabarge Label Labe Label Label Label Label Figure 1.1 Two of each beer is included in each of the samplers (i.e., each sampler has six beers total). The Aggregate Production Plan The Beerstore splits the forecast they develop for their gift packs over the next 4 quarters. They estimate their demand for the year at 6000. The following table contains the fraction of demand by quarter. Apply the forecast to these percentages Fraction of Demand 1/6 Quarter 1 2 4/15 7/30 1/3 The cost of carrying inventory is calculated at S5.00 per unit per period. Jody has been told they cannot afford stockouts and there is no backordering. At the APP level no work can be subcontracted and overtime work by employees is not allowed. However, the company will allow extra inventory to carry over from quarter to quarter and year to year The Beerstore has 5 workers on staff now and each worker can produce on average 100 samplers per quarter. The labor force is fairly liquid and workers can be readily hired or laid off. Hiring costs are $500 per worker and layoff costs are $700 per worker. The workforce at the end of the 4th quarter will be retained Her boss suggested they just follow the demand, a chase strategy, through the quarters to minimize un-needed inventory. However the company HR department always complains about hiring and firing costs so they have suggested a pure level strategy. Jody needs to develop an aggregate production plan (APP) for the data that minimizes costs but complies with all company policies. Help Jody out The Production Problem Jody wishes to use the forecast just developed to help make an Aggregate Production Plan that will then become a Master Production Schedule and drive a Materials Requirements Plan. Jody knows that weekly demand for the gift packs is split evenly between the two samplers (i.e., 50% of demand is Grunge and 50% Deep South). In addition, the following weekly breakdown, in percentage of quarterly forecast amount, has been developed. Help Jody develop an Master Production Schedule for quarter 1 (i., figure out how much they will need to produce in which weeks (1-12) Master Production Schedule as % of Sales Forecast Weeks in Quarter Item NW Grunge Sampler Deep South Hooch Sampler 1 2 3 4 5 7 10 11 12 0% 5% 10% 5% 15% 5% 10% 25% 10% 10% 0% 5% 25% 0% 0% 20% 15% 5% 0% 20% 0% 5% 10% 0% 2 Given the following bill of materials, master production schedule, and inventory master file, generate MRP matrices for each item and identify orders that are past due. If any orders are past due give a recommendation on what course of action to take. If past due, Jody can subcontract the samplers themselves but it costs 4 times the unit cost of each sampler (e.g., subcontract 1 unit NW Grunge= 4*16). Lower level items can be expedited if need be but the cost is twice as much as the unit cost of the item (e.g., expedite 1 unit Walla Walla Mud = 2*$2). Item Master File On Hand Item Scheduled Receipts Lead Time Lot Size Unit Manufactur ing/Purchas ing Cost $6.00 Northwest Grunge Sampler Deep South Hooch Sampler Walla Walla Mud 0 9 1 $6.00 15 1 1 $1.00 10 250 Mt. Hood Dredge Tacoma $1.00 75 301 2 $0.50 40 350 1 Terror $0.50 Tuscaloosa Tomado Meridian Mothball Augusta Augsbarge Labels 1 15 $0.50 20 2 250 $0.50 40 1 $0.01 $0.10 0 100 257 611 2 2 91 Boxes Finance has asked for a preliminary report on how much capital will be needed to purchase the units needed to complete these orders Using the MRP matrices and the notes provided, calculate the capital costs per period and total for the quarter associated with the schedule you have constructed. Inventory holding costs are approximately the same for each lower level item and run about $0.50 per unit per period. There are no inventory costs for the final samplers themselves. Jody also needs to estimate the costs incurred from holding inventory over the quarter. The Beerstore packages specialty beers into gift packs and sells them via the Internet. Its most popular items are the Northwest Grunge Sampler and-the Deep South Hooch Sampler. The product structure trees are given in Figure 1.1 Northwest Grunge Deep South Hooch Sampler Sampler Walla Walla Mud Mt. Hood Dredge Tacoma Terror Tuscaloosa Tomado Meridian Mothball Box Box Augusta Augabarge Label Labe Label Label Label Label Figure 1.1 Two of each beer is included in each of the samplers (i.e., each sampler has six beers total). The Aggregate Production Plan The Beerstore splits the forecast they develop for their gift packs over the next 4 quarters. They estimate their demand for the year at 6000. The following table contains the fraction of demand by quarter. Apply the forecast to these percentages Fraction of Demand 1/6 Quarter 1 2 4/15 7/30 1/3 The cost of carrying inventory is calculated at S5.00 per unit per period. Jody has been told they cannot afford stockouts and there is no backordering. At the APP level no work can be subcontracted and overtime work by employees is not allowed. However, the company will allow extra inventory to carry over from quarter to quarter and year to year The Beerstore has 5 workers on staff now and each worker can produce on average 100 samplers per quarter. The labor force is fairly liquid and workers can be readily hired or laid off. Hiring costs are $500 per worker and layoff costs are $700 per worker. The workforce at the end of the 4th quarter will be retained Her boss suggested they just follow the demand, a chase strategy, through the quarters to minimize un-needed inventory. However the company HR department always complains about hiring and firing costs so they have suggested a pure level strategy. Jody needs to develop an aggregate production plan (APP) for the data that minimizes costs but complies with all company policies. Help Jody out The Production Problem Jody wishes to use the forecast just developed to help make an Aggregate Production Plan that will then become a Master Production Schedule and drive a Materials Requirements Plan. Jody knows that weekly demand for the gift packs is split evenly between the two samplers (i.e., 50% of demand is Grunge and 50% Deep South). In addition, the following weekly breakdown, in percentage of quarterly forecast amount, has been developed. Help Jody develop an Master Production Schedule for quarter 1 (i., figure out how much they will need to produce in which weeks (1-12) Master Production Schedule as % of Sales Forecast Weeks in Quarter Item NW Grunge Sampler Deep South Hooch Sampler 1 2 3 4 5 7 10 11 12 0% 5% 10% 5% 15% 5% 10% 25% 10% 10% 0% 5% 25% 0% 0% 20% 15% 5% 0% 20% 0% 5% 10% 0% 2 Given the following bill of materials, master production schedule, and inventory master file, generate MRP matrices for each item and identify orders that are past due. If any orders are past due give a recommendation on what course of action to take. If past due, Jody can subcontract the samplers themselves but it costs 4 times the unit cost of each sampler (e.g., subcontract 1 unit NW Grunge= 4*16). Lower level items can be expedited if need be but the cost is twice as much as the unit cost of the item (e.g., expedite 1 unit Walla Walla Mud = 2*$2). Item Master File On Hand Item Scheduled Receipts Lead Time Lot Size Unit Manufactur ing/Purchas ing Cost $6.00 Northwest Grunge Sampler Deep South Hooch Sampler Walla Walla Mud 0 9 1 $6.00 15 1 1 $1.00 10 250 Mt. Hood Dredge Tacoma $1.00 75 301 2 $0.50 40 350 1 Terror $0.50 Tuscaloosa Tomado Meridian Mothball Augusta Augsbarge Labels 1 15 $0.50 20 2 250 $0.50 40 1 $0.01 $0.10 0 100 257 611 2 2 91 Boxes Finance has asked for a preliminary report on how much capital will be needed to purchase the units needed to complete these orders Using the MRP matrices and the notes provided, calculate the capital costs per period and total for the quarter associated with the schedule you have constructed. Inventory holding costs are approximately the same for each lower level item and run about $0.50 per unit per period. There are no inventory costs for the final samplers themselves. Jody also needs to estimate the costs incurred from holding inventory over the quarterStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started