Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please show work and solve using formulas on paper. please do not show exel work Use a pricing-out strategy to check if either model would

please show work and solve using formulas on paper. please do not show exel work

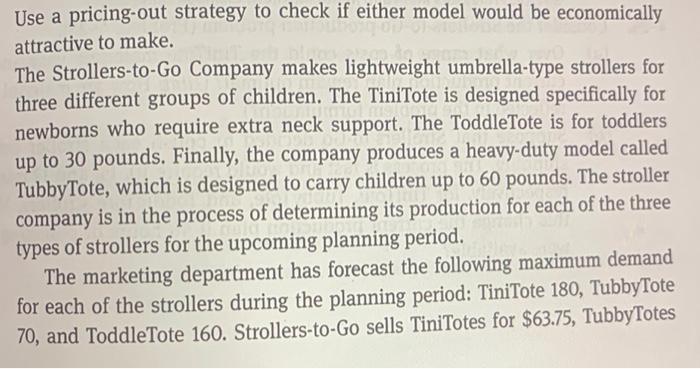

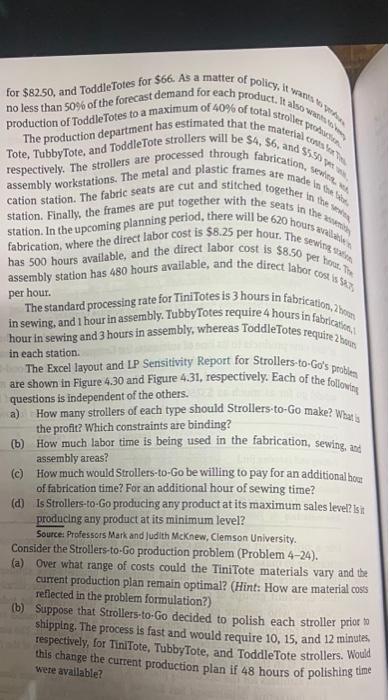

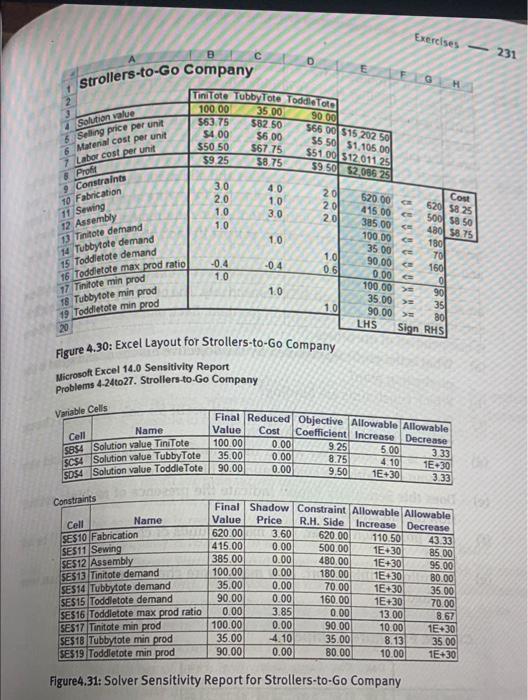

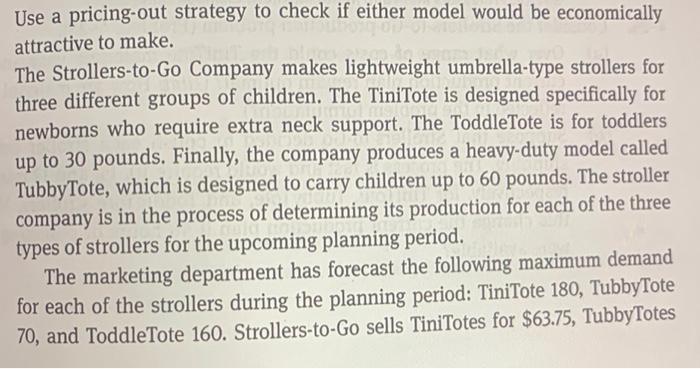

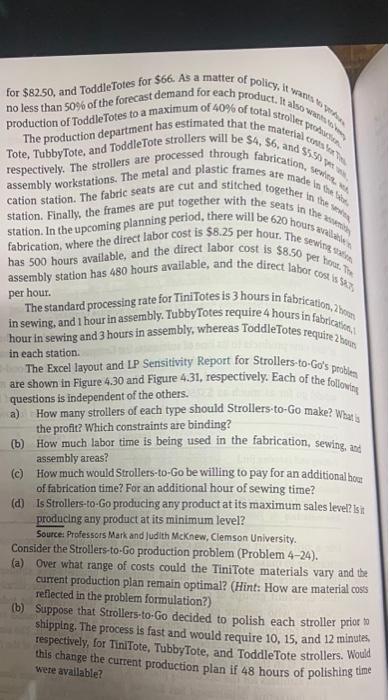

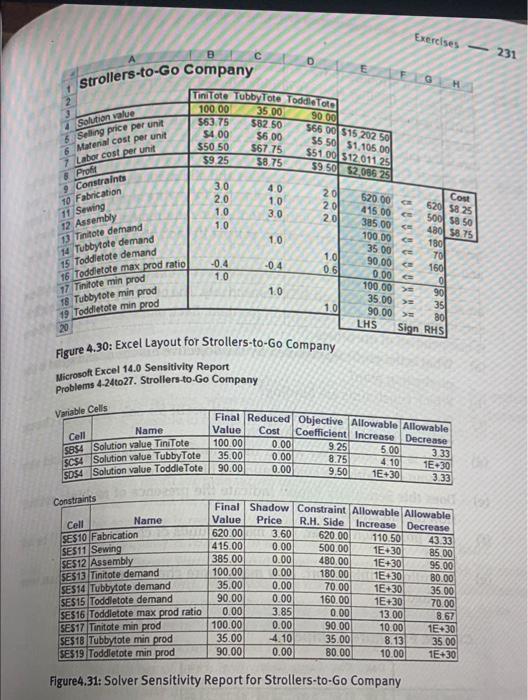

Use a pricing-out strategy to check if either model would be economically attractive to make. The Strollers-to-Go Company makes lightweight umbrella-type strollers for three different groups of children. The TiniTote is designed specifically for newborns who require extra neck support. The ToddleTote is for toddlers up to 30 pounds. Finally, the company produces a heavy-duty model called TubbyTote, which is designed to carry children up to 60 pounds. The stroller company is in the process of determining its production for each of the three types of strollers for the upcoming planning period. The marketing department has forecast the following maximum demand for each of the strollers during the planning period: TiniTote 180, TubbyTote 70, and ToddleTote 160. Strollers-to-Go sells TiniTotes for $63.75, TubbyTotes no less than 50% of the forecast demand for each product, it also The production department has estimated that the material ToOI, per hour. The standard processing rate for TiniTotes is 3 hours in fabrication, 2 booly sewing, and 1 hour in assembly. TubbyTotes require 4 hours in fabricatco, The Excel layout and LP Sensitivity Report for Strollers-to-Go's probleted questions is independent of the others. a) How many strollers of each type should Strollers.to-Go make? What is the profit? Which constraints are binding? (b) How much labor time is being used in the fabrication, sewing, and assembly areas? (c) How much would Strollers-to-Go be willing to pay for an additional hoct of fabrication time? For an additional hour of sewing time? (d) Is Strollers-to-Go producing any product at its maximum sales level? is it producing any product at its minimum level? Source: Professors Mark and judith Mcknew, Clemson University. Consider the Strollers-to-Go production problem (Problem 4-24). (a) Over what range of costs could the TiniTote materials vary and the current production plan remain optimal? (Hint: How are material coss reflected in the problem formulation?) (b) Suppose that Strollers-to.Go decided to polish each stroller priot in shipping. The process is fast and would require 10,15 , and 12 minutes, respectively, for TiniTote, TubbyTote, and ToddleTote strollers. Would this change the current production plan if 48 hours of polishing time wete available? Flgure 4.30: Excel Layout for Strollers-to-Go Company Microsoft Excel 14.0 Sensitivity Report Problems 4.24to27. Strollers to.Go Company Figure4.31: Solver Sensitivity Report for Strollers-to-Go Company Use a pricing-out strategy to check if either model would be economically attractive to make. The Strollers-to-Go Company makes lightweight umbrella-type strollers for three different groups of children. The TiniTote is designed specifically for newborns who require extra neck support. The ToddleTote is for toddlers up to 30 pounds. Finally, the company produces a heavy-duty model called TubbyTote, which is designed to carry children up to 60 pounds. The stroller company is in the process of determining its production for each of the three types of strollers for the upcoming planning period. The marketing department has forecast the following maximum demand for each of the strollers during the planning period: TiniTote 180, TubbyTote 70, and ToddleTote 160. Strollers-to-Go sells TiniTotes for $63.75, TubbyTotes no less than 50% of the forecast demand for each product, it also The production department has estimated that the material ToOI, per hour. The standard processing rate for TiniTotes is 3 hours in fabrication, 2 booly sewing, and 1 hour in assembly. TubbyTotes require 4 hours in fabricatco, The Excel layout and LP Sensitivity Report for Strollers-to-Go's probleted questions is independent of the others. a) How many strollers of each type should Strollers.to-Go make? What is the profit? Which constraints are binding? (b) How much labor time is being used in the fabrication, sewing, and assembly areas? (c) How much would Strollers-to-Go be willing to pay for an additional hoct of fabrication time? For an additional hour of sewing time? (d) Is Strollers-to-Go producing any product at its maximum sales level? is it producing any product at its minimum level? Source: Professors Mark and judith Mcknew, Clemson University. Consider the Strollers-to-Go production problem (Problem 4-24). (a) Over what range of costs could the TiniTote materials vary and the current production plan remain optimal? (Hint: How are material coss reflected in the problem formulation?) (b) Suppose that Strollers-to.Go decided to polish each stroller priot in shipping. The process is fast and would require 10,15 , and 12 minutes, respectively, for TiniTote, TubbyTote, and ToddleTote strollers. Would this change the current production plan if 48 hours of polishing time wete available? Flgure 4.30: Excel Layout for Strollers-to-Go Company Microsoft Excel 14.0 Sensitivity Report Problems 4.24to27. Strollers to.Go Company Figure4.31: Solver Sensitivity Report for Strollers-to-Go Company

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started