Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please solve nunber 5 , 6 and 7 please many student ask to solve it but no one do it we dont know why no

please solve nunber 5 , 6 and 7 please many student ask to solve it but no one do it we dont know why no body amswer these

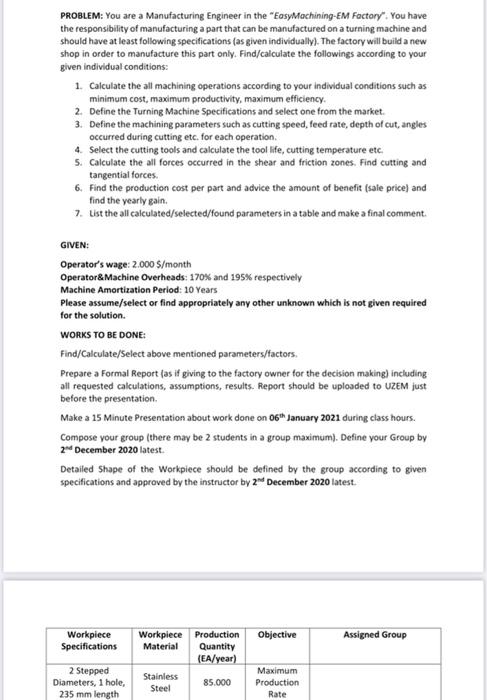

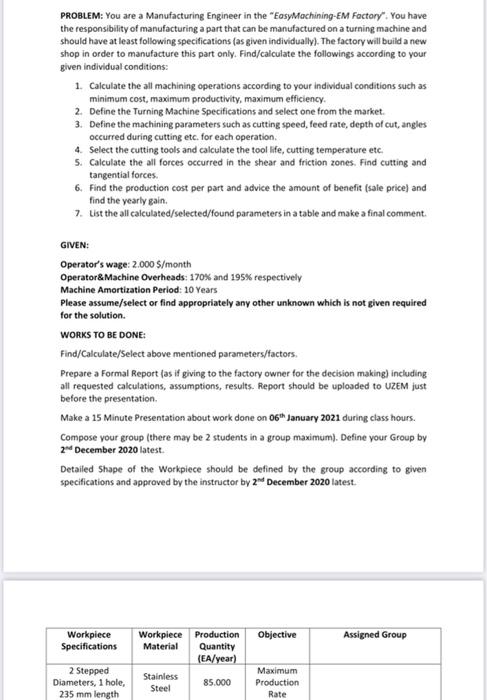

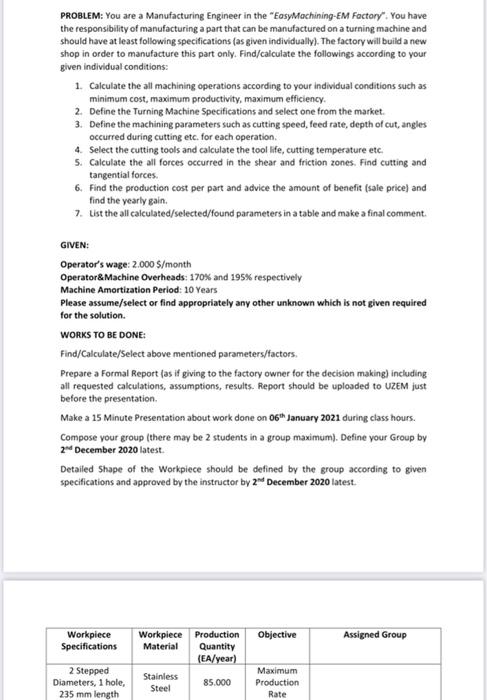

PROBLEM: You are a Manufacturing Engineer in the "EasyMachining-EM Factory": You have the responsibility of manufacturing a part that can be manufactured on a turning machine and should have at least following specifications (as given individually). The factory will build a new shop in order to manufacture this part only. Find/calculate the followings according to your given individual conditions: 1. Calculate the all machining operations according to your individual conditions such as minimum cost, maximum productivity, maximum efficiency 2. Define the Turning Machine Specifications and select one from the market. 3. Define the machining parameters such as cutting speed, feed rate, depth of cut, angles occurred during cutting etc. for each operation 4. Select the cutting tools and calculate the tool life, cutting temperature etc S. Calculate the all forces occurred in the shear and friction zones. Find cutting and tangential forces. 6. Find the production cost per part and advice the amount of benefit (sale price) and find the yearly gain. 7. List the all calculated/selected/found parameters in a table and make a final comment. GIVEN: Operator's wage: 2.000 S/month Operator&Machine Overheads: 170% and 195% respectively Machine Amortization Period: 10 Years Please assume/select or find appropriately any other unknown which is not given required for the solution. WORKS TO BE DONE Find/Calculate/Select above mentioned parameters/factors. Prepare a Formal Report as if giving to the factory owner for the decision making) including all requested calculations, assumptions, results. Report should be uploaded to UZEM just before the presentation Make a 15 Minute Presentation about work done on 06h January 2021 during class hours. Compose your group (there may be 2 students in a group maximum). Define your Group by 2 December 2020 latest. Detailed Shape of the Workpiece should be defined by the group according to given specifications and approved by the instructor by 2 December 2020 latest Workpiece Specifications Objective Assigned Group Workpiece Production Material Quantity (EA/year) Stainless 85.000 Steel 2 Stepped Diameters, 1 hole, 235 mm length Maximum Production Rate PROBLEM: You are a Manufacturing Engineer in the "EasyMachining-EM Factory": You have the responsibility of manufacturing a part that can be manufactured on a turning machine and should have at least following specifications (as given individually). The factory will build a new shop in order to manufacture this part only. Find/calculate the followings according to your given individual conditions: 1. Calculate the all machining operations according to your individual conditions such as minimum cost, maximum productivity, maximum efficiency 2. Define the Turning Machine Specifications and select one from the market. 3. Define the machining parameters such as cutting speed, feed rate, depth of cut, angles occurred during cutting etc. for each operation 4. Select the cutting tools and calculate the tool life, cutting temperature etc S. Calculate the all forces occurred in the shear and friction zones. Find cutting and tangential forces. 6. Find the production cost per part and advice the amount of benefit (sale price) and find the yearly gain. 7. List the all calculated/selected/found parameters in a table and make a final comment. GIVEN: Operator's wage: 2.000 S/month Operator&Machine Overheads: 170% and 195% respectively Machine Amortization Period: 10 Years Please assume/select or find appropriately any other unknown which is not given required for the solution. WORKS TO BE DONE Find/Calculate/Select above mentioned parameters/factors. Prepare a Formal Report as if giving to the factory owner for the decision making) including all requested calculations, assumptions, results. Report should be uploaded to UZEM just before the presentation Make a 15 Minute Presentation about work done on 06h January 2021 during class hours. Compose your group (there may be 2 students in a group maximum). Define your Group by 2 December 2020 latest. Detailed Shape of the Workpiece should be defined by the group according to given specifications and approved by the instructor by 2 December 2020 latest Workpiece Specifications Objective Assigned Group Workpiece Production Material Quantity (EA/year) Stainless 85.000 Steel 2 Stepped Diameters, 1 hole, 235 mm length Maximum Production Rate PROBLEM: You are a Manufacturing Engineer in the "EasyMachining-EM Factory": You have the responsibility of manufacturing a part that can be manufactured on a turning machine and should have at least following specifications (as given individually). The factory will build a new shop in order to manufacture this part only. Find/calculate the followings according to your given individual conditions: 1. Calculate the all machining operations according to your individual conditions such as minimum cost, maximum productivity, maximum efficiency 2. Define the Turning Machine Specifications and select one from the market. 3. Define the machining parameters such as cutting speed, feed rate, depth of cut, angles occurred during cutting etc. for each operation 4. Select the cutting tools and calculate the tool life, cutting temperature etc S. Calculate the all forces occurred in the shear and friction zones. Find cutting and tangential forces. 6. Find the production cost per part and advice the amount of benefit (sale price) and find the yearly gain. 7. List the all calculated/selected/found parameters in a table and make a final comment. GIVEN: Operator's wage: 2.000 S/month Operator&Machine Overheads: 170% and 195% respectively Machine Amortization Period: 10 Years Please assume/select or find appropriately any other unknown which is not given required for the solution. WORKS TO BE DONE Find/Calculate/Select above mentioned parameters/factors. Prepare a Formal Report as if giving to the factory owner for the decision making) including all requested calculations, assumptions, results. Report should be uploaded to UZEM just before the presentation Make a 15 Minute Presentation about work done on 06h January 2021 during class hours. Compose your group (there may be 2 students in a group maximum). Define your Group by 2 December 2020 latest. Detailed Shape of the Workpiece should be defined by the group according to given specifications and approved by the instructor by 2 December 2020 latest Workpiece Specifications Objective Assigned Group Workpiece Production Material Quantity (EA/year) Stainless 85.000 Steel 2 Stepped Diameters, 1 hole, 235 mm length Maximum Production Rate PROBLEM: You are a Manufacturing Engineer in the "EasyMachining-EM Factory": You have the responsibility of manufacturing a part that can be manufactured on a turning machine and should have at least following specifications (as given individually). The factory will build a new shop in order to manufacture this part only. Find/calculate the followings according to your given individual conditions: 1. Calculate the all machining operations according to your individual conditions such as minimum cost, maximum productivity, maximum efficiency 2. Define the Turning Machine Specifications and select one from the market. 3. Define the machining parameters such as cutting speed, feed rate, depth of cut, angles occurred during cutting etc. for each operation 4. Select the cutting tools and calculate the tool life, cutting temperature etc S. Calculate the all forces occurred in the shear and friction zones. Find cutting and tangential forces. 6. Find the production cost per part and advice the amount of benefit (sale price) and find the yearly gain. 7. List the all calculated/selected/found parameters in a table and make a final comment. GIVEN: Operator's wage: 2.000 S/month Operator&Machine Overheads: 170% and 195% respectively Machine Amortization Period: 10 Years Please assume/select or find appropriately any other unknown which is not given required for the solution. WORKS TO BE DONE Find/Calculate/Select above mentioned parameters/factors. Prepare a Formal Report as if giving to the factory owner for the decision making) including all requested calculations, assumptions, results. Report should be uploaded to UZEM just before the presentation Make a 15 Minute Presentation about work done on 06h January 2021 during class hours. Compose your group (there may be 2 students in a group maximum). Define your Group by 2 December 2020 latest. Detailed Shape of the Workpiece should be defined by the group according to given specifications and approved by the instructor by 2 December 2020 latest Workpiece Specifications Objective Assigned Group Workpiece Production Material Quantity (EA/year) Stainless 85.000 Steel 2 Stepped Diameters, 1 hole, 235 mm length Maximum Production Rate

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started