Please solve part A for the next linear programming question

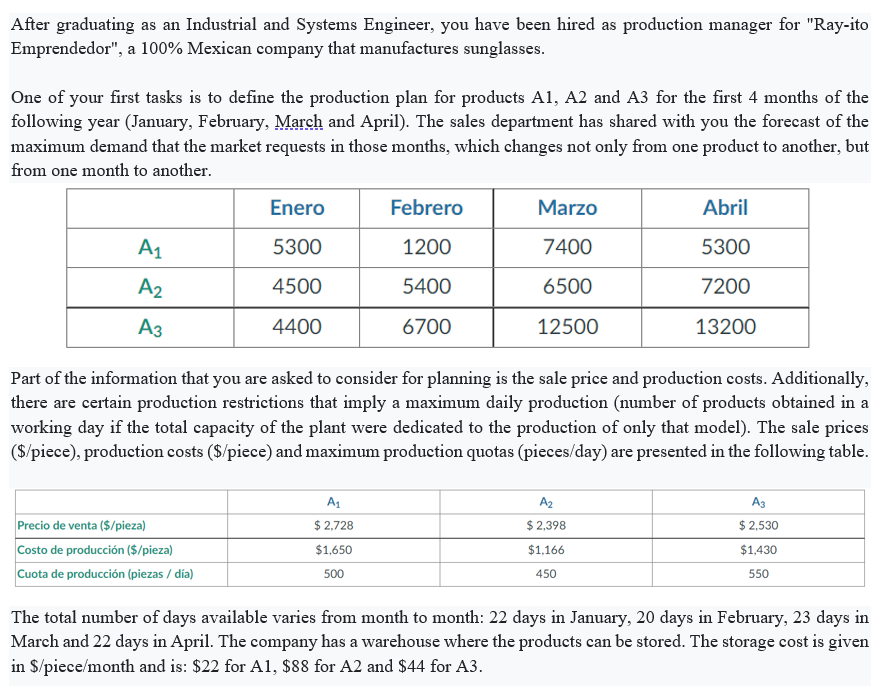

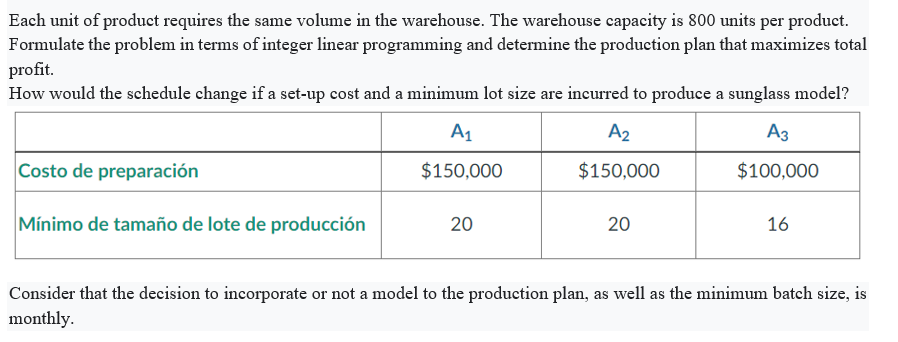

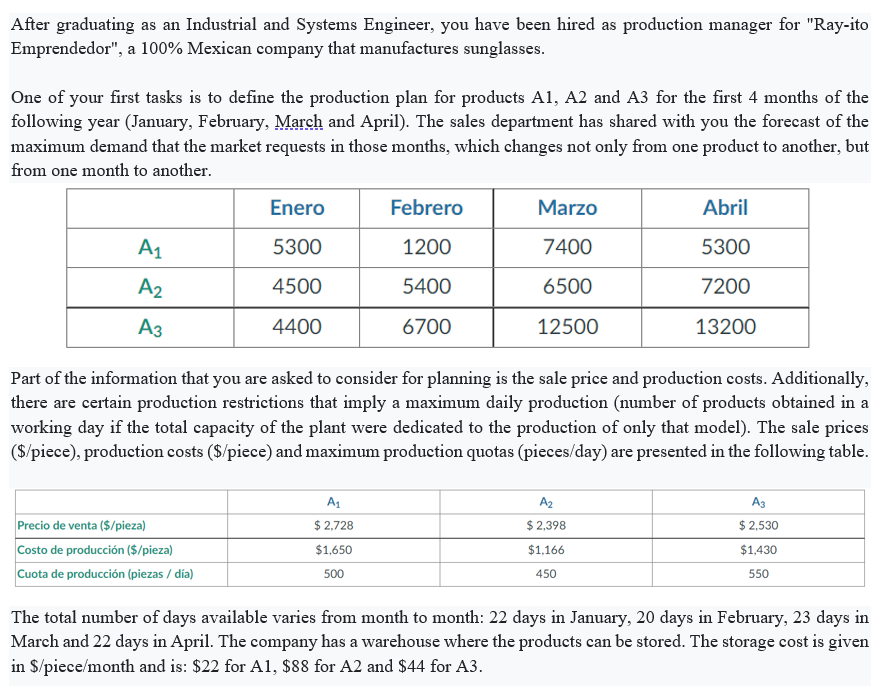

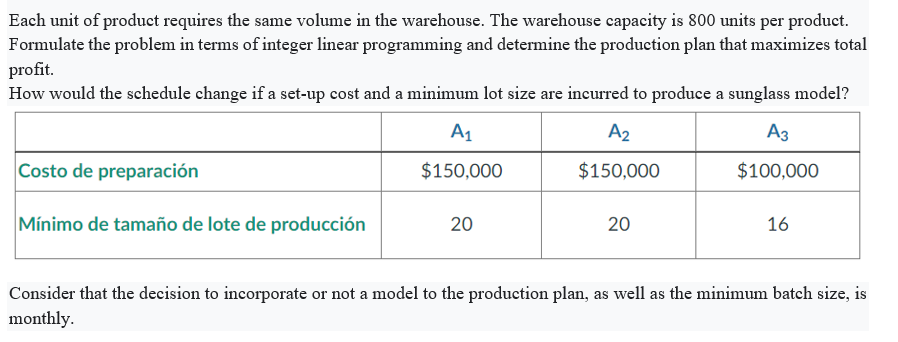

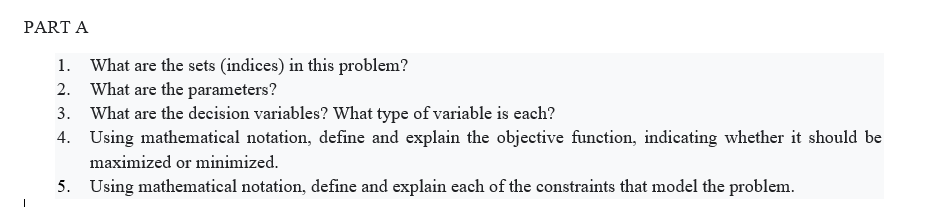

After graduating as an Industrial and Systems Engineer, you have been hired as production manager for "Ray-ito Emprendedor", a 100\% Mexican company that manufactures sunglasses. One of your first tasks is to define the production plan for products A1, A2 and A3 for the first 4 months of the following year (January, February, March and April). The sales department has shared with you the forecast of the maximum demand that the market requests in those months, which changes not only from one product to another, but from one month to another. Part of the information that you are asked to consider for planning is the sale price and production costs. Additionally, there are certain production restrictions that imply a maximum daily production (number of products obtained in a working day if the total capacity of the plant were dedicated to the production of only that model). The sale prices (\$/piece), production costs (\$/piece) and maximum production quotas (pieces/day) are presented in the following table. The total number of days available varies from month to month: 22 days in January, 20 days in February, 23 days in March and 22 days in April. The company has a warehouse where the products can be stored. The storage cost is given in $/ piece/month and is: $22 for A1,$88 for A2 and $44 for A3. Each unit of product requires the same volume in the warehouse. The warehouse capacity is 800 units per product. Formulate the problem in terms of integer linear programming and determine the production plan that maximizes tota profit. How would the schedule change if a set-up cost and a minimum lot size are incurred to produce a sunglass model? Consider that the decision to incorporate or not a model to the production plan, as well as the minimum batch size, i monthly. 1. What are the sets (indices) in this problem? 2. What are the parameters? 3. What are the decision variables? What type of variable is each? 4. Using mathematical notation, define and explain the objective function, indicating whether it should be maximized or minimized. 5. Using mathematical notation, define and explain each of the constraints that model the problem. After graduating as an Industrial and Systems Engineer, you have been hired as production manager for "Ray-ito Emprendedor", a 100\% Mexican company that manufactures sunglasses. One of your first tasks is to define the production plan for products A1, A2 and A3 for the first 4 months of the following year (January, February, March and April). The sales department has shared with you the forecast of the maximum demand that the market requests in those months, which changes not only from one product to another, but from one month to another. Part of the information that you are asked to consider for planning is the sale price and production costs. Additionally, there are certain production restrictions that imply a maximum daily production (number of products obtained in a working day if the total capacity of the plant were dedicated to the production of only that model). The sale prices (\$/piece), production costs (\$/piece) and maximum production quotas (pieces/day) are presented in the following table. The total number of days available varies from month to month: 22 days in January, 20 days in February, 23 days in March and 22 days in April. The company has a warehouse where the products can be stored. The storage cost is given in $/ piece/month and is: $22 for A1,$88 for A2 and $44 for A3. Each unit of product requires the same volume in the warehouse. The warehouse capacity is 800 units per product. Formulate the problem in terms of integer linear programming and determine the production plan that maximizes tota profit. How would the schedule change if a set-up cost and a minimum lot size are incurred to produce a sunglass model? Consider that the decision to incorporate or not a model to the production plan, as well as the minimum batch size, i monthly. 1. What are the sets (indices) in this problem? 2. What are the parameters? 3. What are the decision variables? What type of variable is each? 4. Using mathematical notation, define and explain the objective function, indicating whether it should be maximized or minimized. 5. Using mathematical notation, define and explain each of the constraints that model the