Answered step by step

Verified Expert Solution

Question

1 Approved Answer

PLEASE SOLVE THE ABOVE PROBLEM WITH ASPEN PLUS AND SCREENSHOOT THE ANSWER TOO. THANK YOU. Question 1 Production and separation of ethyl acetate Ethyl acetate

PLEASE SOLVE THE ABOVE PROBLEM WITH ASPEN PLUS AND SCREENSHOOT THE ANSWER TOO. THANK YOU.

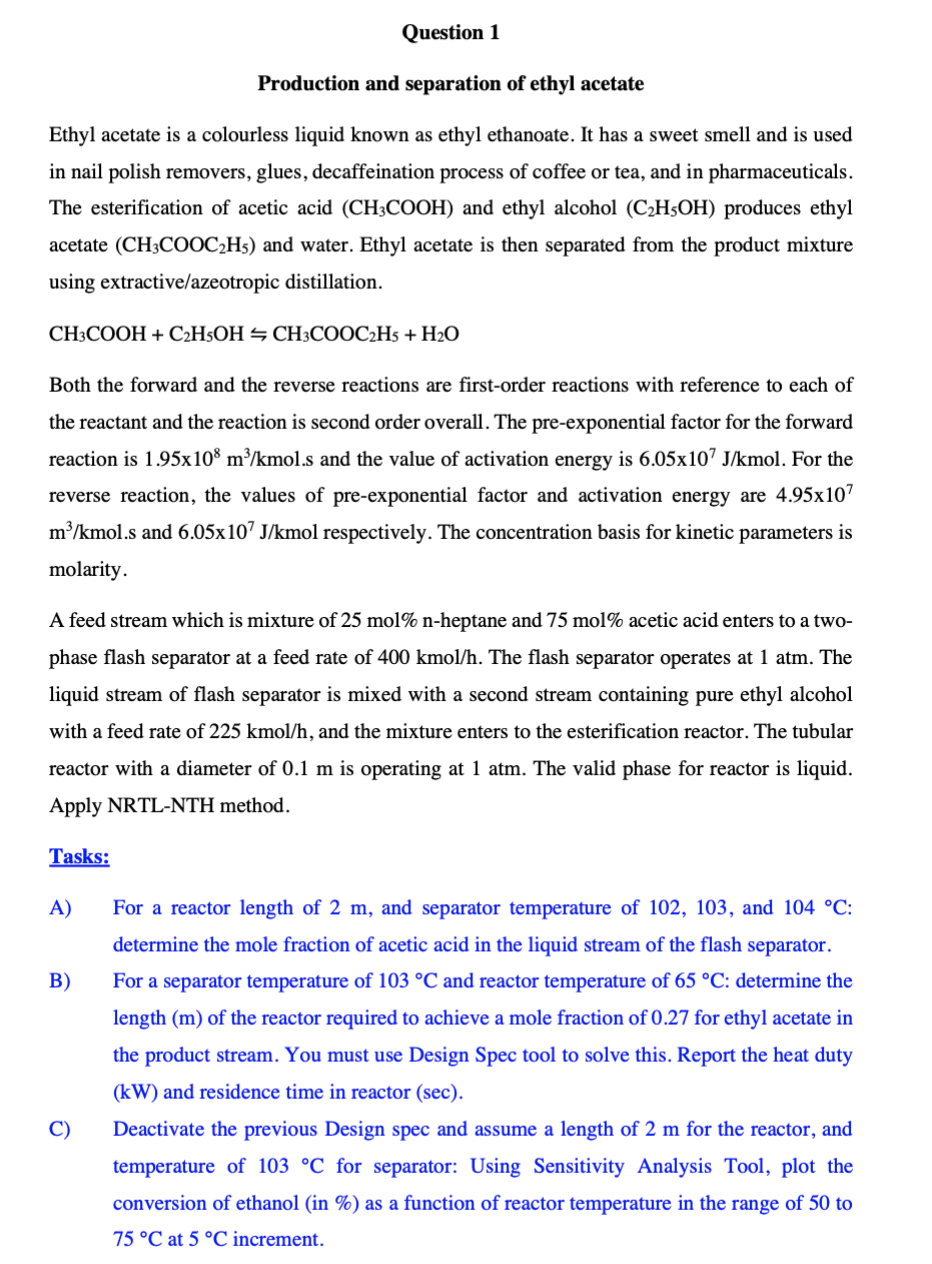

Question 1 Production and separation of ethyl acetate Ethyl acetate is a colourless liquid known as ethyl ethanoate. It has a sweet smell and is used in nail polish removers, glues, decaffeination process of coffee or tea, and in pharmaceuticals. The esterification of acetic acid (CH3COOH) and ethyl alcohol (C2H5OH) produces ethyl acetate (CH3COOC2H5) and water. Ethyl acetate is then separated from the product mixture using extractive/azeotropic distillation. CH3COOH+C2H5OHCH3COOC2H5+H2O Both the forward and the reverse reactions are first-order reactions with reference to each of the reactant and the reaction is second order overall. The pre-exponential factor for the forward reaction is 1.95108m3/kmol.s and the value of activation energy is 6.05107J/kmol. For the reverse reaction, the values of pre-exponential factor and activation energy are 4.95107 m3/kmol.s and 6.05107J/kmol respectively. The concentration basis for kinetic parameters is molarity. A feed stream which is mixture of 25mol%n-heptane and 75mol% acetic acid enters to a twophase flash separator at a feed rate of 400kmol/h. The flash separator operates at 1atm. The liquid stream of flash separator is mixed with a second stream containing pure ethyl alcohol with a feed rate of 225kmol/h, and the mixture enters to the esterification reactor. The tubular reactor with a diameter of 0.1m is operating at 1atm. The valid phase for reactor is liquid. Apply NRTL-NTH method. Tasks: A) For a reactor length of 2m, and separator temperature of 102,103 , and 104C : determine the mole fraction of acetic acid in the liquid stream of the flash separator. B) For a separator temperature of 103C and reactor temperature of 65C : determine the length (m) of the reactor required to achieve a mole fraction of 0.27 for ethyl acetate in the product stream. You must use Design Spec tool to solve this. Report the heat duty (kW) and residence time in reactor (sec). C) Deactivate the previous Design spec and assume a length of 2m for the reactor, and temperature of 103C for separator: Using Sensitivity Analysis Tool, plot the conversion of ethanol (in \%) as a function of reactor temperature in the range of 50 to 75C at 5C incrementStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started