- Plot all 4 graphs on one page - Use subplot to plot 4 plots - and use Matlab pleas.e.

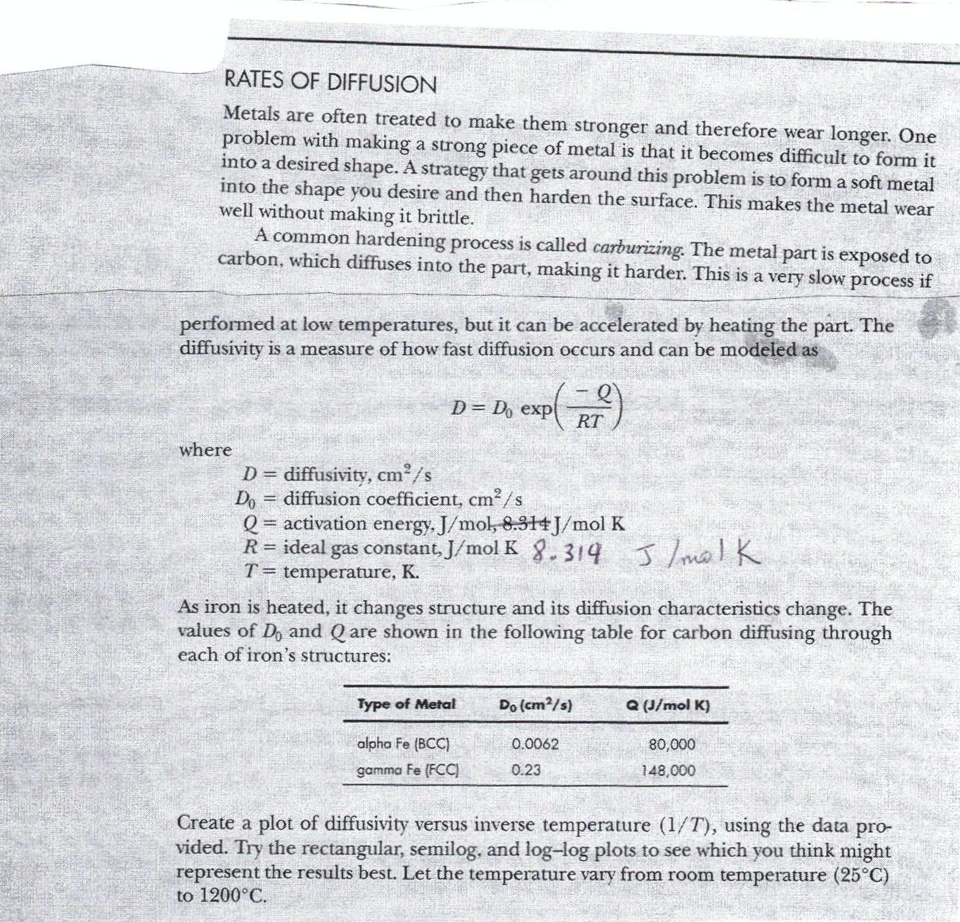

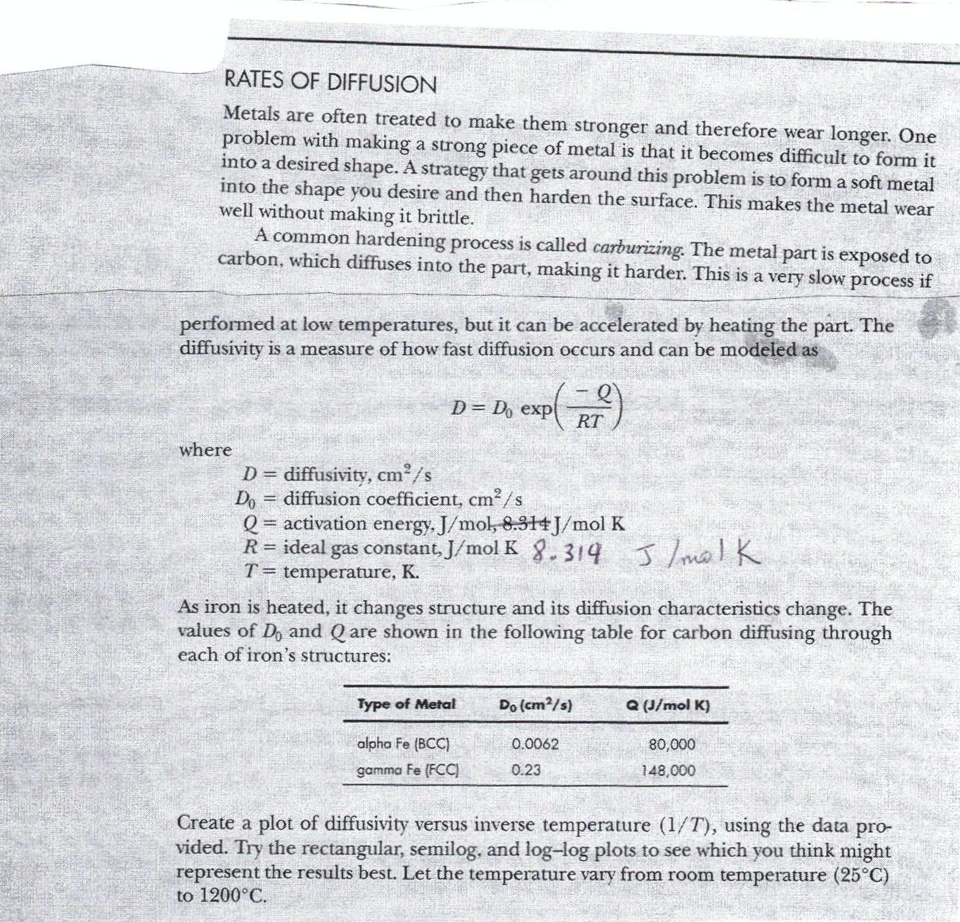

RATES OF DIFFUSION Metals are often treated to make them stronger and therefore wear longer. One problem with making a strong piece of metal is that it becomes difficult to form it into a desired shape. A strategy that gets around this problem is to form a soft metal into the shape you desire and then harden the surface. This makes the metal wear well without making it brittle. A common hardening process is called carburizing. The metal part is exposed to carbon, which diffuses into the part, making it harder. This is a very slow process if performed at low temperatures, but it can be accelerated by heating the part. The diffusivity is a measure of how fast diffusion occurs and can be modeled as D=D, expl) where D= diffusivity, cm/s Do = diffusion coefficient, cm/s Q = activation energy, J/mol, 8.314J/mol K R = ideal gas constant, J/mol K 8.314 J/molk T= temperature, K. As iron is heated, it changes structure and its diffusion characteristics change. The values of D, and Q are shown in the following table for carbon diffusing through each of iron's structures: Type of Metal Do (cm/s) Q (J/mol K) alpha Fe (BCC) gamma Fe (FCC) 0.0062 0.23 80,000 148,000 Create a plot of diffusivity versus inverse temperature (1/T), using the data pro- vided. Try the rectangular, semilog, and log-log plots to see which you think might represent the results best. Let the temperature vary from room temperature (25C) to 1200C. RATES OF DIFFUSION Metals are often treated to make them stronger and therefore wear longer. One problem with making a strong piece of metal is that it becomes difficult to form it into a desired shape. A strategy that gets around this problem is to form a soft metal into the shape you desire and then harden the surface. This makes the metal wear well without making it brittle. A common hardening process is called carburizing. The metal part is exposed to carbon, which diffuses into the part, making it harder. This is a very slow process if performed at low temperatures, but it can be accelerated by heating the part. The diffusivity is a measure of how fast diffusion occurs and can be modeled as D=D, expl) where D= diffusivity, cm/s Do = diffusion coefficient, cm/s Q = activation energy, J/mol, 8.314J/mol K R = ideal gas constant, J/mol K 8.314 J/molk T= temperature, K. As iron is heated, it changes structure and its diffusion characteristics change. The values of D, and Q are shown in the following table for carbon diffusing through each of iron's structures: Type of Metal Do (cm/s) Q (J/mol K) alpha Fe (BCC) gamma Fe (FCC) 0.0062 0.23 80,000 148,000 Create a plot of diffusivity versus inverse temperature (1/T), using the data pro- vided. Try the rectangular, semilog, and log-log plots to see which you think might represent the results best. Let the temperature vary from room temperature (25C) to 1200C