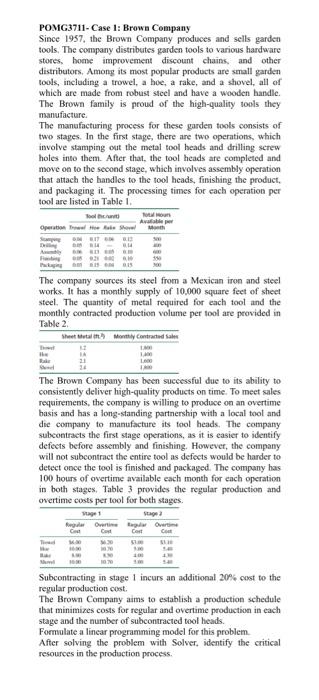

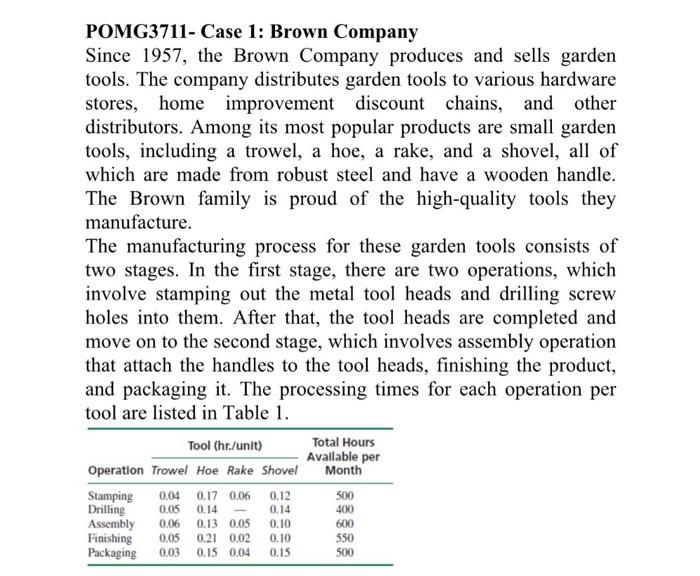

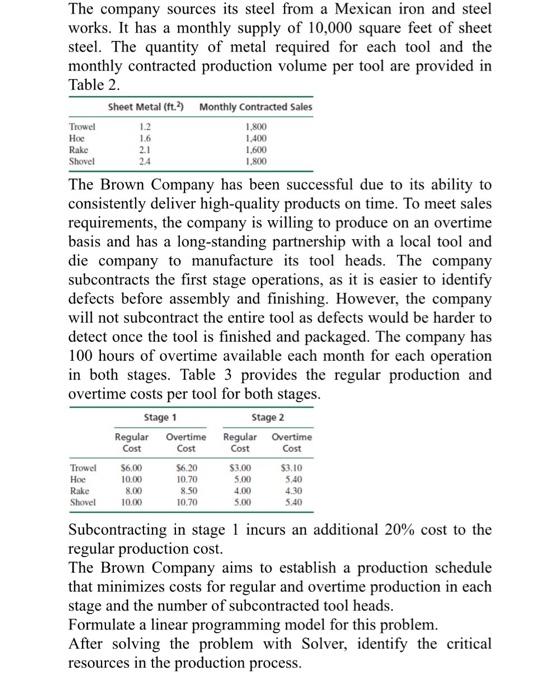

POMG3711- Case 1: Brown Company Since 1957, the Brown Company produces and sells garden tools. The conspany distributes garden tools to various hardware stores, boene improvement discount chains, and other distributors. Among its most popelar products are small garden tools, including a trowel, a boe, a rake, and a shovel, all of which are made from robust steel and have a wooden handle. The Brown family is proud of the high-quality tools they manufacture. The manufacturing process for these garden tools consists of two stages. In the first stage, there are two operations, which involve stamping out the metal tool heads and drilling screw holes into them. After that, the tool heads are completed and move on to the second stage, which involves assembly operation that attach the handles to the tool heads, finishing the product, and packaging it. The processing times for each operation per tool are listed in Table 1. The company sources its steel from a Mexican iron and steel works. It has a monthly supply of 10,000 square feet of sheet steel. The quantity of metal required for each tool and the monthly contracted production volume per tool are provided in Tablc 2 , The Brown Company has been successful due to its ability to consistently deliver high-quality products on time. To meet sales requirements, the company is willing to produce on an overtime basis and has a long-standing partnership with a local tool and die company to manufacture its fool heads. The company subeontracts the first stage operations, as it is easier to identify defects before assembly and finishing. However, the company will not subcontract the entire tool as defects would be harder to detect onee the tool is finished and packaged. The company has 100 hours of overtime available each month for each operation in both stages, Table 3 provides the regular production and overtime costs per tool for both stages. Subcontracting in stage 1 incurs an additional 20% cost to the regular production cost: The Brown Company aims to establish a production schedule that minimizes costs for regular and overtime production in each stage and the number of subcontracted tool heads. Formulate a linear programming model for this problem. After solving the problem with Solver, identify the critical resources in the production process. POMG3711- Case 1: Brown Company Since 1957, the Brown Company produces and sells garden tools. The company distributes garden tools to various hardware stores, home improvement discount chains, and other distributors. Among its most popular products are small garden tools, including a trowel, a hoe, a rake, and a shovel, all of which are made from robust steel and have a wooden handle. The Brown family is proud of the high-quality tools they manufacture. The manufacturing process for these garden tools consists of two stages. In the first stage, there are two operations, which involve stamping out the metal tool heads and drilling screw holes into them. After that, the tool heads are completed and move on to the second stage, which involves assembly operation that attach the handles to the tool heads, finishing the product, and packaging it. The processing times for each operation per The company sources its steel from a Mexican iron and steel works. It has a monthly supply of 10,000 square feet of sheet steel. The quantity of metal required for each tool and the monthly contracted production volume per tool are provided in Table 2. The Brown Company has been successful due to its ability to consistently deliver high-quality products on time. To meet sales requirements, the company is willing to produce on an overtime basis and has a long-standing partnership with a local tool and die company to manufacture its tool heads. The company subcontracts the first stage operations, as it is easier to identify defects before assembly and finishing. However, the company will not subcontract the entire tool as defects would be harder to detect once the tool is finished and packaged. The company has 100 hours of overtime available each month for each operation in both stages. Table 3 provides the regular production and overtime costs per tool for both stages. Subcontracting in stage 1 incurs an additional 20% cost to the regular production cost. The Brown Company aims to establish a production schedule that minimizes costs for regular and overtime production in each stage and the number of subcontracted tool heads. Formulate a linear programming model for this problem. After solving the problem with Solver, identify the critical resources in the production process. POMG3711- Case 1: Brown Company Since 1957, the Brown Company produces and sells garden tools. The conspany distributes garden tools to various hardware stores, boene improvement discount chains, and other distributors. Among its most popelar products are small garden tools, including a trowel, a boe, a rake, and a shovel, all of which are made from robust steel and have a wooden handle. The Brown family is proud of the high-quality tools they manufacture. The manufacturing process for these garden tools consists of two stages. In the first stage, there are two operations, which involve stamping out the metal tool heads and drilling screw holes into them. After that, the tool heads are completed and move on to the second stage, which involves assembly operation that attach the handles to the tool heads, finishing the product, and packaging it. The processing times for each operation per tool are listed in Table 1. The company sources its steel from a Mexican iron and steel works. It has a monthly supply of 10,000 square feet of sheet steel. The quantity of metal required for each tool and the monthly contracted production volume per tool are provided in Tablc 2 , The Brown Company has been successful due to its ability to consistently deliver high-quality products on time. To meet sales requirements, the company is willing to produce on an overtime basis and has a long-standing partnership with a local tool and die company to manufacture its fool heads. The company subeontracts the first stage operations, as it is easier to identify defects before assembly and finishing. However, the company will not subcontract the entire tool as defects would be harder to detect onee the tool is finished and packaged. The company has 100 hours of overtime available each month for each operation in both stages, Table 3 provides the regular production and overtime costs per tool for both stages. Subcontracting in stage 1 incurs an additional 20% cost to the regular production cost: The Brown Company aims to establish a production schedule that minimizes costs for regular and overtime production in each stage and the number of subcontracted tool heads. Formulate a linear programming model for this problem. After solving the problem with Solver, identify the critical resources in the production process. POMG3711- Case 1: Brown Company Since 1957, the Brown Company produces and sells garden tools. The company distributes garden tools to various hardware stores, home improvement discount chains, and other distributors. Among its most popular products are small garden tools, including a trowel, a hoe, a rake, and a shovel, all of which are made from robust steel and have a wooden handle. The Brown family is proud of the high-quality tools they manufacture. The manufacturing process for these garden tools consists of two stages. In the first stage, there are two operations, which involve stamping out the metal tool heads and drilling screw holes into them. After that, the tool heads are completed and move on to the second stage, which involves assembly operation that attach the handles to the tool heads, finishing the product, and packaging it. The processing times for each operation per The company sources its steel from a Mexican iron and steel works. It has a monthly supply of 10,000 square feet of sheet steel. The quantity of metal required for each tool and the monthly contracted production volume per tool are provided in Table 2. The Brown Company has been successful due to its ability to consistently deliver high-quality products on time. To meet sales requirements, the company is willing to produce on an overtime basis and has a long-standing partnership with a local tool and die company to manufacture its tool heads. The company subcontracts the first stage operations, as it is easier to identify defects before assembly and finishing. However, the company will not subcontract the entire tool as defects would be harder to detect once the tool is finished and packaged. The company has 100 hours of overtime available each month for each operation in both stages. Table 3 provides the regular production and overtime costs per tool for both stages. Subcontracting in stage 1 incurs an additional 20% cost to the regular production cost. The Brown Company aims to establish a production schedule that minimizes costs for regular and overtime production in each stage and the number of subcontracted tool heads. Formulate a linear programming model for this problem. After solving the problem with Solver, identify the critical resources in the production process