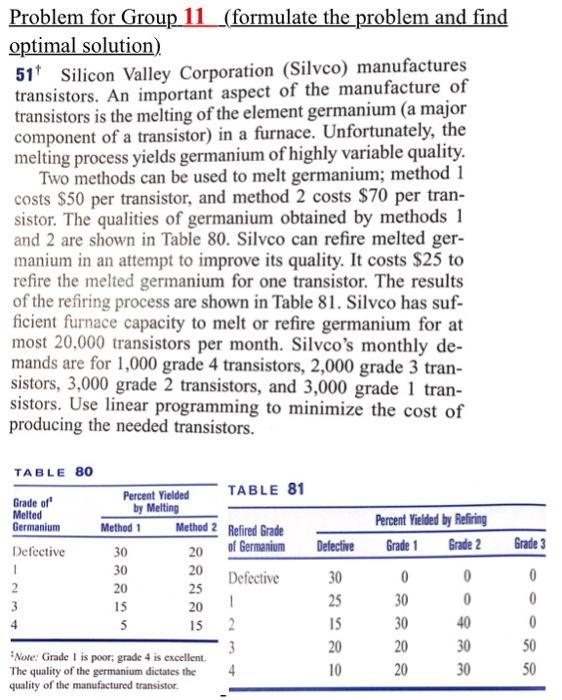

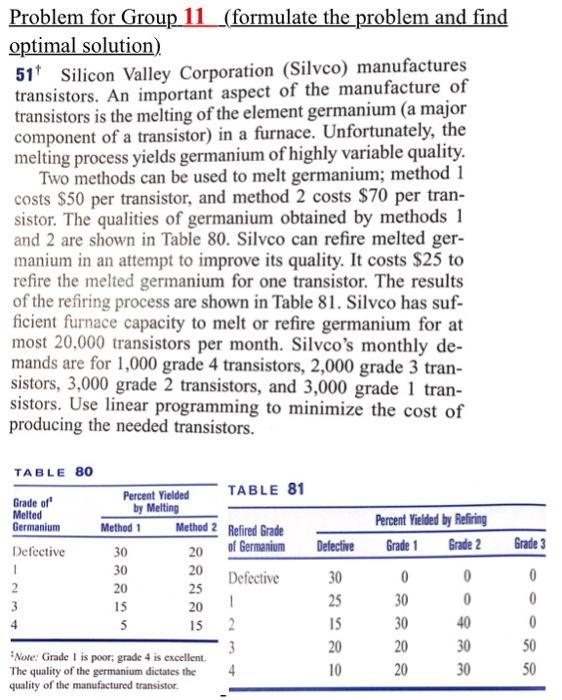

PP&C IT Quiz/-07 January 20219 1 ID-Number-...........4 Name.......... Signature 1 Consider a product with a daily demand of 500 units, a setup cost per production run of $100,- a daily holding cost per unit of $0.20, and an annual production rate of 219,000 units. The firm operates and experiences demand 365 days per year. Suppose that management mistakenly used the basic EOQ model to calculate the batch size instead of using the production order quantity model. How much money per year has that mistake cost the company I sh U.SI W: EN Problem for Group 11 (formulate the problem and find optimal solution) 51* Silicon Valley Corporation (Silvco) manufactures transistors. An important aspect of the manufacture of transistors is the melting of the element germanium (a major component of a transistor) in a furnace. Unfortunately, the melting process yields germanium of highly variable quality. Two methods can be used to melt germanium; method 1 costs $50 per transistor, and method 2 costs $70 per tran- sistor. The qualities of germanium obtained by methods 1 and 2 are shown in Table 80. Silvo can refire melted ger- manium in an attempt to improve its quality. It costs $25 to refire the melted germanium for one transistor. The results of the refiring process are shown in Table 81. Silvo has suf- ficient furnace capacity to melt or refire germanium for at most 20,000 transistors per month. Silvco's monthly de- mands are for 1,000 grade 4 transistors, 2,000 grade 3 tran- sistors, 3,000 grade 2 transistors, and 3,000 grade 1 tran- sistors. Use linear programming to minimize the cost of producing the needed transistors. Defective Grade 3 TABLE 80 Percent Vielded TABLE 81 Grade of Melted by Melting Germanium Method 1 Method 2 Refired Grade Defective 30 20 of Germanium 1 30 20 Defective 2 20 25 3 15 20 1 4 5 15 2 3 Note: Grade 1 is poor, grade 4 is excellent The quality of the germanium dictates the quality of the manufactured transistor 30 25 Percent Vielded by Refiring Grade 1 Grade 2 0 0 30 0 30 40 20 30 20 30 15 20 10 0 0 0 50 50 PP&C IT Quiz/-07 January 20219 1 ID-Number-...........4 Name.......... Signature 1 Consider a product with a daily demand of 500 units, a setup cost per production run of $100,- a daily holding cost per unit of $0.20, and an annual production rate of 219,000 units. The firm operates and experiences demand 365 days per year. Suppose that management mistakenly used the basic EOQ model to calculate the batch size instead of using the production order quantity model. How much money per year has that mistake cost the company I sh U.SI W: EN Problem for Group 11 (formulate the problem and find optimal solution) 51* Silicon Valley Corporation (Silvco) manufactures transistors. An important aspect of the manufacture of transistors is the melting of the element germanium (a major component of a transistor) in a furnace. Unfortunately, the melting process yields germanium of highly variable quality. Two methods can be used to melt germanium; method 1 costs $50 per transistor, and method 2 costs $70 per tran- sistor. The qualities of germanium obtained by methods 1 and 2 are shown in Table 80. Silvo can refire melted ger- manium in an attempt to improve its quality. It costs $25 to refire the melted germanium for one transistor. The results of the refiring process are shown in Table 81. Silvo has suf- ficient furnace capacity to melt or refire germanium for at most 20,000 transistors per month. Silvco's monthly de- mands are for 1,000 grade 4 transistors, 2,000 grade 3 tran- sistors, 3,000 grade 2 transistors, and 3,000 grade 1 tran- sistors. Use linear programming to minimize the cost of producing the needed transistors. Defective Grade 3 TABLE 80 Percent Vielded TABLE 81 Grade of Melted by Melting Germanium Method 1 Method 2 Refired Grade Defective 30 20 of Germanium 1 30 20 Defective 2 20 25 3 15 20 1 4 5 15 2 3 Note: Grade 1 is poor, grade 4 is excellent The quality of the germanium dictates the quality of the manufactured transistor 30 25 Percent Vielded by Refiring Grade 1 Grade 2 0 0 30 0 30 40 20 30 20 30 15 20 10 0 0 0 50 50