Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Practice Problem You have just been asked to 'fix the problem in operations,' where it seems that orders are always late. Your first action is

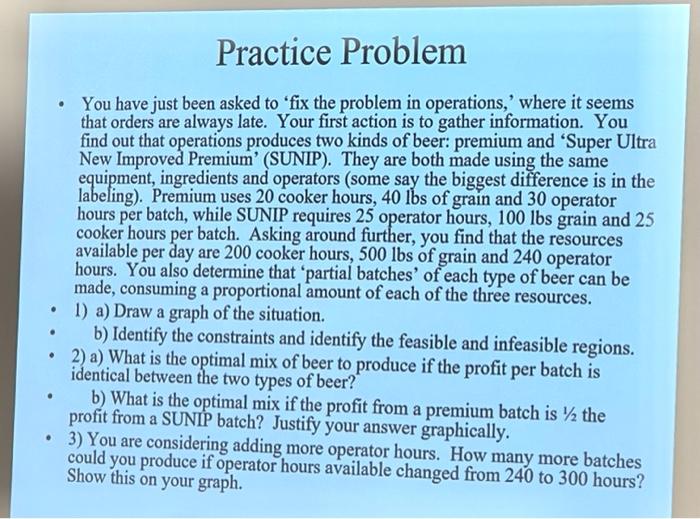

Practice Problem You have just been asked to 'fix the problem in operations,' where it seems that orders are always late. Your first action is to gather information. You find out that operations produces two kinds of beer: premium and 'Super Ultra New Improved Premium' (SUNIP). They are both made using the same equipment, ingredients and operators (some say the biggest difference is in the labeling). Premium uses 20 cooker hours, 40 lbs of grain and 30 operator hours per batch, while SUNIP requires 25 operator hours, 100 lbs grain and 25 cooker hours per batch. Asking around further, you find that the resources available per day are 200 cooker hours, 500 lbs of grain and 240 operator hours. You also determine that 'partial batches' of each type of beer can be made, consuming a proportional amount of each of the three resources. 1) a) Draw a graph of the situation. b) Identify the constraints and identify the feasible and infeasible regions. 2) a) What is the optimal mix of beer to produce if the profit per batch is identical between the two types of beer? b) What is the optimal mix if the profit from a premium batch is the profit from a SUNIP batch? Justify your answer graphically. 3) You are considering adding more operator hours. How many more batches could you produce if operator hours available changed from 240 to 300 hours? Show this on your graph.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started