Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Prepared cash budget and pro forma statement of profit and loss for July, August, and September from the following information. After graduating from college in

Prepared cash budget and pro forma statement of profit and loss for July, August, and September from the following information.

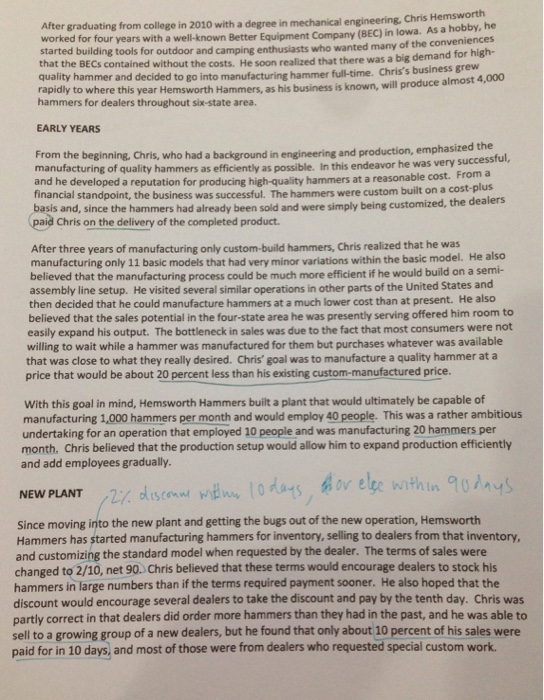

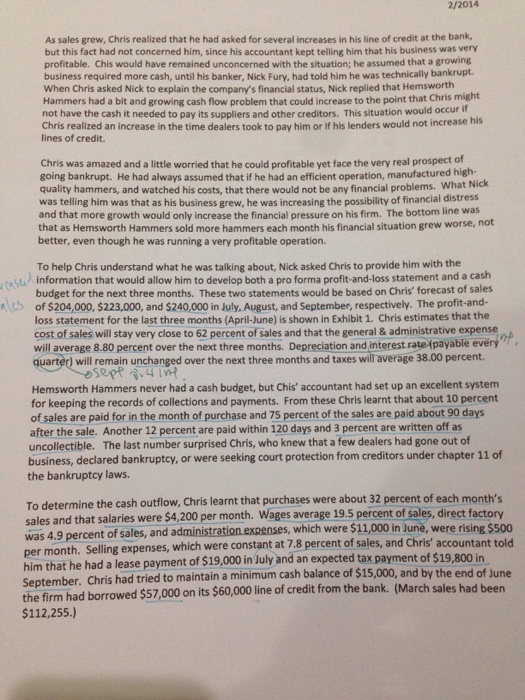

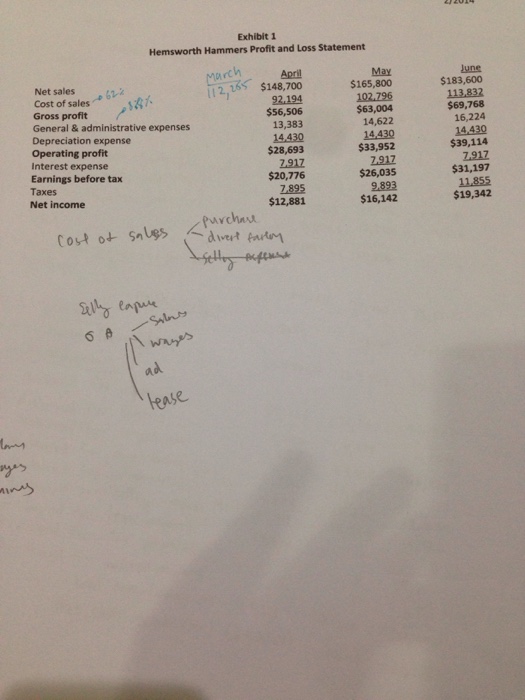

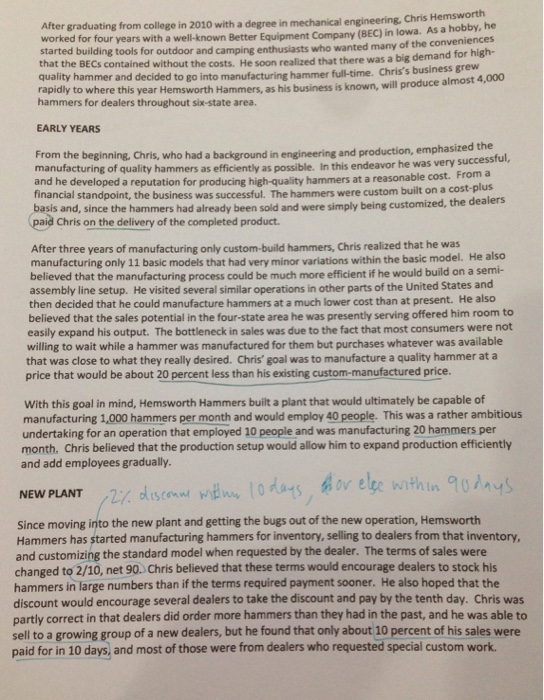

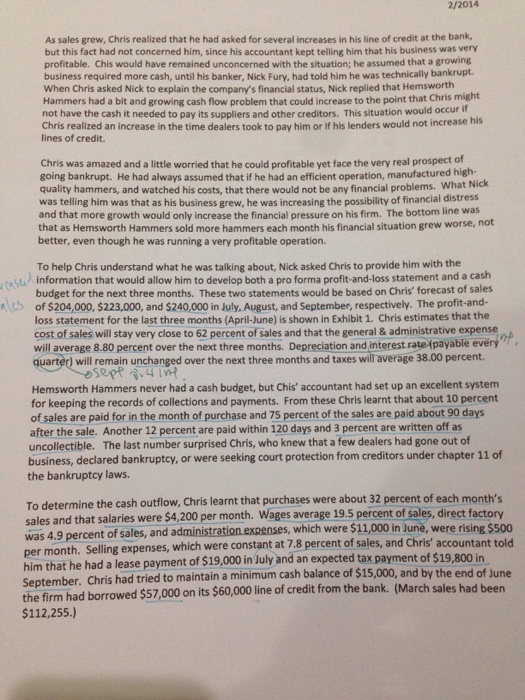

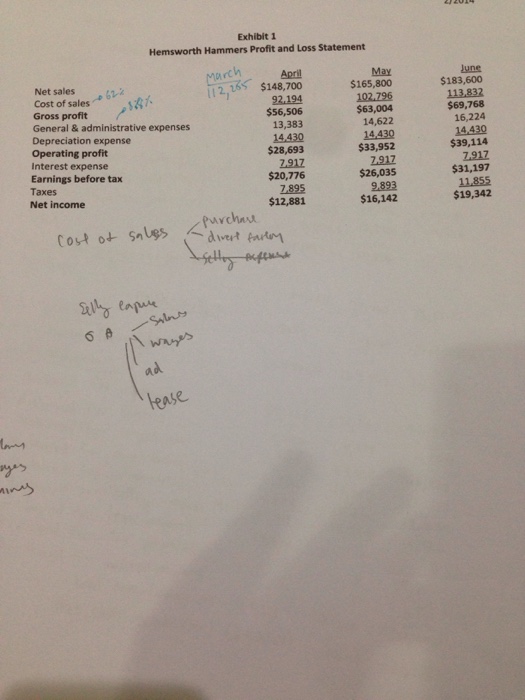

After graduating from college in 2010 with a degree in mechanical engineering. Chris Hemsworth worked for four years with a well-known Better Equipment Company (BEC) in Iowa. As a hobby started building tools for outdoor and camping enthusiasts who wanted many of the conveniences that the BECs contained without the costs. He soon realized that there was a big demand for high-quality hammer and decided to go into manufacturing hammer full-time. Chris's business grew rapidly to where this year Hemsworth Hammers, as his business is known, will produce almost 4,000 hammers for dealers throughout six-state area. EARLY YEARS From the beginning, Chris, who had a background m engineering and production, emphasized the manufacturing of quality hammers as efficiently as possible In this endeavor he was very success u, and he developed a reputation for producing high-quality hammers at a reasonable cost. From a financial standpoint, the business was successful. The hammers were custom built on a cost-plus basis and, since the hammers had already been sold and were simply being customized, the dealers paid Chris on the delivery of the completed product. After three years of manufacturing only custom-build hammers. Chris realized that he was manufacturing only 11 basic models that had very minor variations within the basic model. He also believed that the manufacturing process could be much more efficient if he would build on a semi-assembly line setup. He visited several similar operations in other parts of the United States and then decided that he could manufacture hammers at a much lower cost than at present. He also believed that the sales potential in the four-state area he was presently serving offered him room to easily expand his output. The bottleneck m sales was due to the fact that most consumers were not willing to wait while a hammer was manufactured for them but purchases whatever was available that was close to what they really desired. Chris' goal was to manufacture a quality hammer at a price that would be about 20 percent less than his existing custom-manufactured price. With this goal in mind, Hemsworth Hammers built a plant that would ultimately be capable of manufacturing 1,000 hammers per month and would employ 40 people. This was a rather ambitious undertaking for an operation that employed 10 people and was manufacturing 20 hammers per month. Chris believed that the production setup would allow him to expand production efficiently and add employees gradually. NEW PLANT Since moving into the new plant and getting the bugs out of the new operation, Hemsworth Hammers has started manufacturing hammers for inventory, selling to dealers from that inventory, and customizing the standard model when requested by the dealer. The terms of sales were changed to 2/10, net 90. Chris believed that these terms would encourage dealers to stock his hammers in large numbers than if the terms required payment sooner. He also hoped that the discount would encourage several dealers to take the discount and pay by the tenth day. Chris was partly correct in that dealers did order more hammers than they had in the past, and he was able to sell to a growing group of a new dealers, but he found that only about 10 percent of his sales were paid for in 10 days, and most of those were from dealers who requested special custom work

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started