Answered step by step

Verified Expert Solution

Question

1 Approved Answer

As a senior manufacturing engineer at a company that makes welded tool cabinets and related products, you are asked to optimize a dissimilar metal

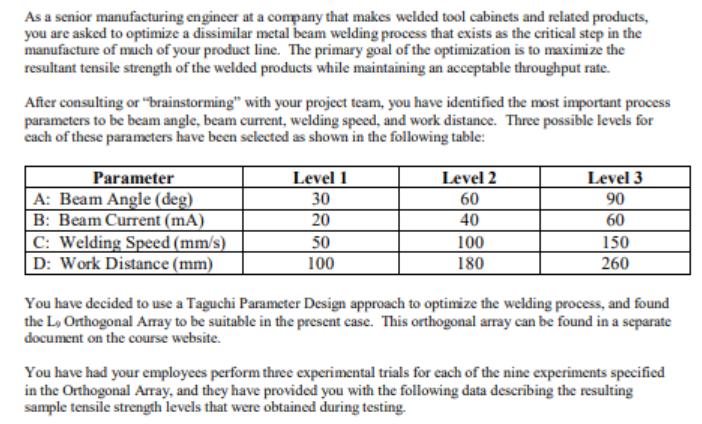

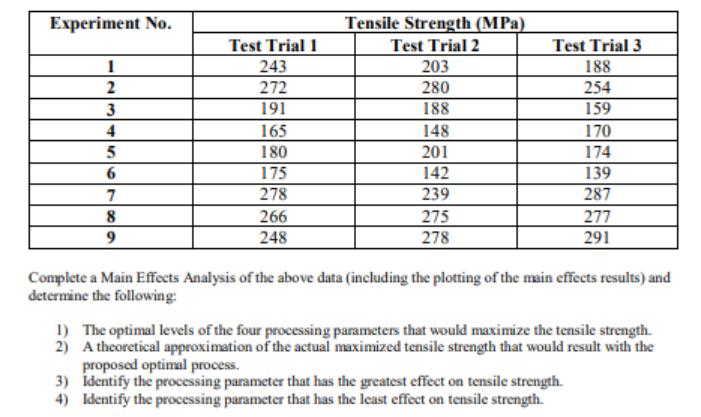

As a senior manufacturing engineer at a company that makes welded tool cabinets and related products, you are asked to optimize a dissimilar metal beam welding process that exists as the critical step in the manufacture of much of your product line. The primary goal of the optimization is to maximize the resultant tensile strength of the welded products while maintaining an acceptable throughput rate. After consulting or "brainstorming" with your project team, you have identified the most important process parameters to be beam angle, beam current, welding speed, and work distance. Three possible levels for each of these parameters have been selected as shown in the following table: Parameter A: Beam Angle (deg) B: Beam Current (mA) C: Welding Speed (mm/s) D: Work Distance (mm) Level 1 30 20 50 100 Level 2 60 40 100 180 Level 3 90 60 150 260 You have decided to use a Taguchi Parameter Design approach to optimize the welding process, and found the L, Orthogonal Array to be suitable in the present case. This orthogonal array can be found in a separate document on the course website. You have had your employees perform three experimental trials for each of the nine experiments specified in the Orthogonal Array, and they have provided you with the following data describing the resulting sample tensile strength levels that were obtained during testing. Experiment No. 1 2 3 4 3) 4) 5 6 7 8 9 Test Trial 1 243 272 191 165 180 175 278 266 248 Tensile Strength (MPa) Test Trial 2 203 280 188 148 201 142 239 275 278 Test Trial 3 188 254 159 170 174 139 287 277 291 Complete a Main Effects Analysis of the above data (including the plotting of the main effects results) and determine the following: 2) 1) The optimal levels of the four processing parameters that would maximize the tensile strength. A theoretical approximation of the actual maximized tensile strength that would result with the proposed optimal process. Identify the processing parameter that has the greatest effect on tensile strength. Identify the processing parameter that has the least effect on tensile strength.

Step by Step Solution

★★★★★

3.54 Rating (151 Votes )

There are 3 Steps involved in it

Step: 1

In order to complete a Main Effects Analysis based on the data provided we need to follow these steps 1 Calculate the average tensile strength for eac...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started