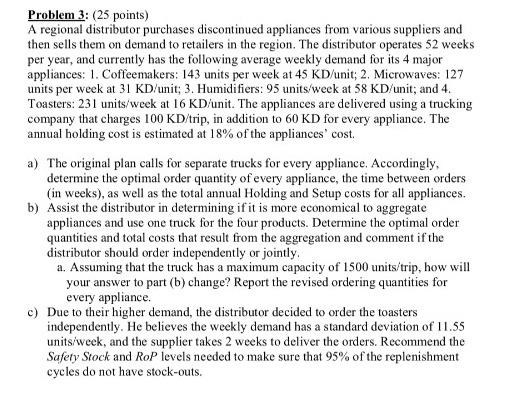

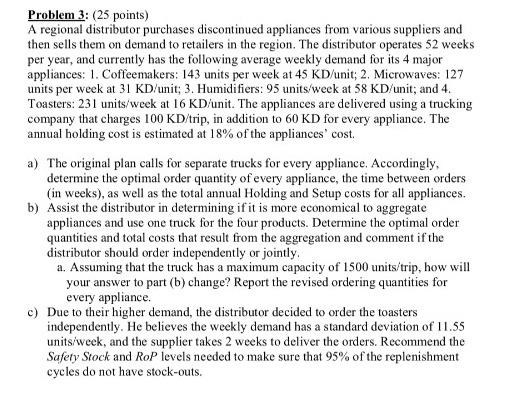

Problem 3: (25 points) A regional distributor purchases discontinued appliances from various suppliers and then sells them on demand to retailers in the region. The distributor operates 52 weeks per year, and currently has the following average weekly demand for its 4 major appliances: 1. Coffeemakers: 143 units per week at 45 KD/unit; 2. Microwaves: 127 units per week at 31 KD/unit; 3. Humidifiers: 95 units/week at 58 KD/unit, and 4. Toasters: 231 units/week at 16 KD/unit. The appliances are delivered using a trucking company that charges 100 KD/trip, in addition to 60 KD for every appliance. The annual holding cost is estimated at 18% of the appliances' cost. a) The original plan calls for separate trucks for every appliance. Accordingly, determine the optimal order quantity of every appliance, the time between orders (in weeks), as well as the total annual Holding and Setup costs for all appliances. b) Assist the distributor in determining if it is more economical to aggregate appliances and use one truck for the four products. Determine the optimal order quantities and total costs that result from the aggregation and comment if the distributor should order independently or jointly a. Assuming that the truck has a maximum capacity of 1500 units/trip, how will your answer to part (b) change? Report the revised ordering quantities for every appliance. c) Due to their higher demand, the distributor decided to order the toasters independently. He believes the weekly demand has a standard deviation of 11.55 units/week, and the supplier takes 2 weeks to deliver the orders. Recommend the Safety Stock and RoP levels needed to make sure that 95% of the replenishment cycles do not have stock-outs. Problem 3: (25 points) A regional distributor purchases discontinued appliances from various suppliers and then sells them on demand to retailers in the region. The distributor operates 52 weeks per year, and currently has the following average weekly demand for its 4 major appliances: 1. Coffeemakers: 143 units per week at 45 KD/unit; 2. Microwaves: 127 units per week at 31 KD/unit; 3. Humidifiers: 95 units/week at 58 KD/unit, and 4. Toasters: 231 units/week at 16 KD/unit. The appliances are delivered using a trucking company that charges 100 KD/trip, in addition to 60 KD for every appliance. The annual holding cost is estimated at 18% of the appliances' cost. a) The original plan calls for separate trucks for every appliance. Accordingly, determine the optimal order quantity of every appliance, the time between orders (in weeks), as well as the total annual Holding and Setup costs for all appliances. b) Assist the distributor in determining if it is more economical to aggregate appliances and use one truck for the four products. Determine the optimal order quantities and total costs that result from the aggregation and comment if the distributor should order independently or jointly a. Assuming that the truck has a maximum capacity of 1500 units/trip, how will your answer to part (b) change? Report the revised ordering quantities for every appliance. c) Due to their higher demand, the distributor decided to order the toasters independently. He believes the weekly demand has a standard deviation of 11.55 units/week, and the supplier takes 2 weeks to deliver the orders. Recommend the Safety Stock and RoP levels needed to make sure that 95% of the replenishment cycles do not have stock-outs