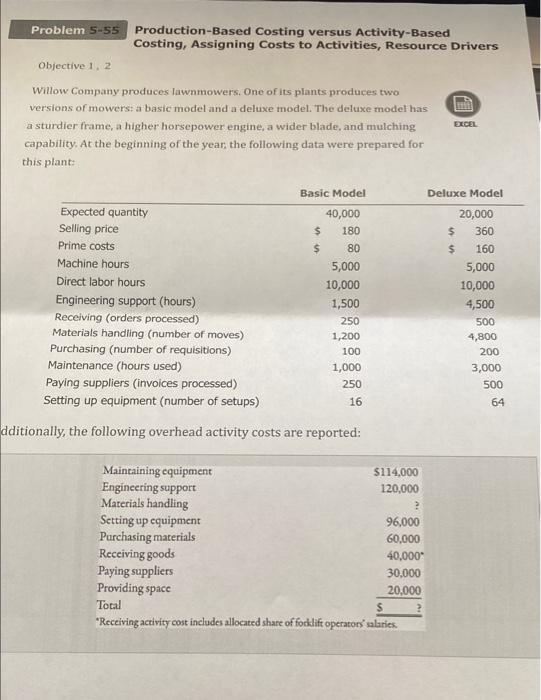

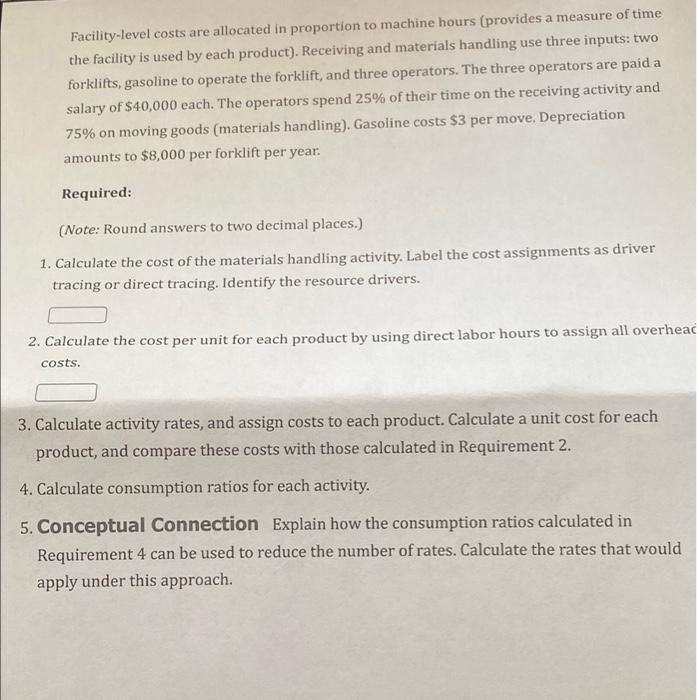

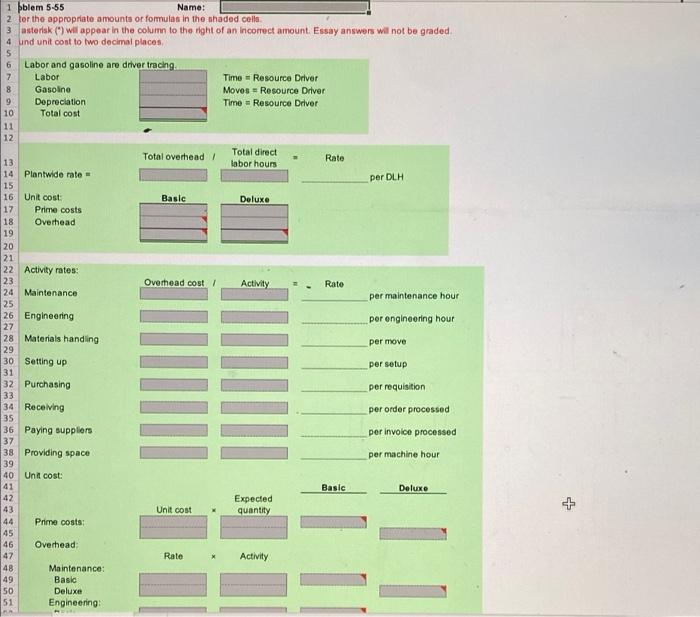

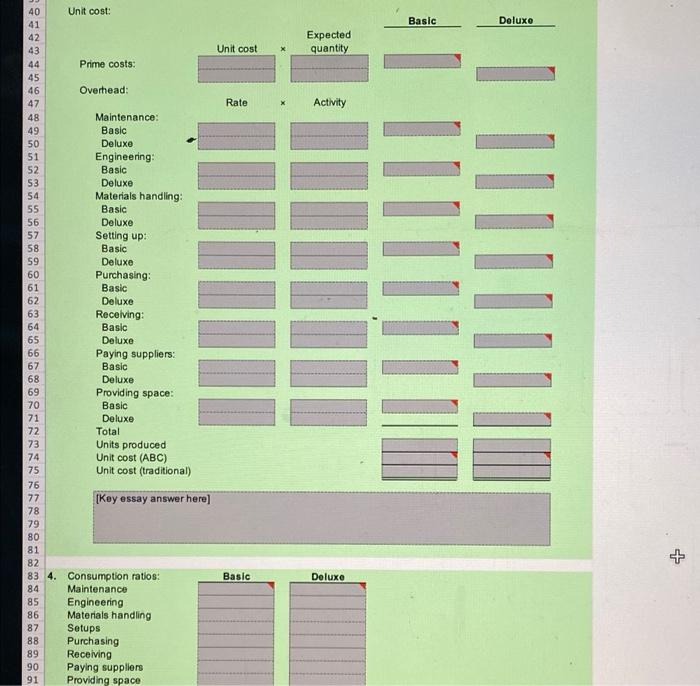

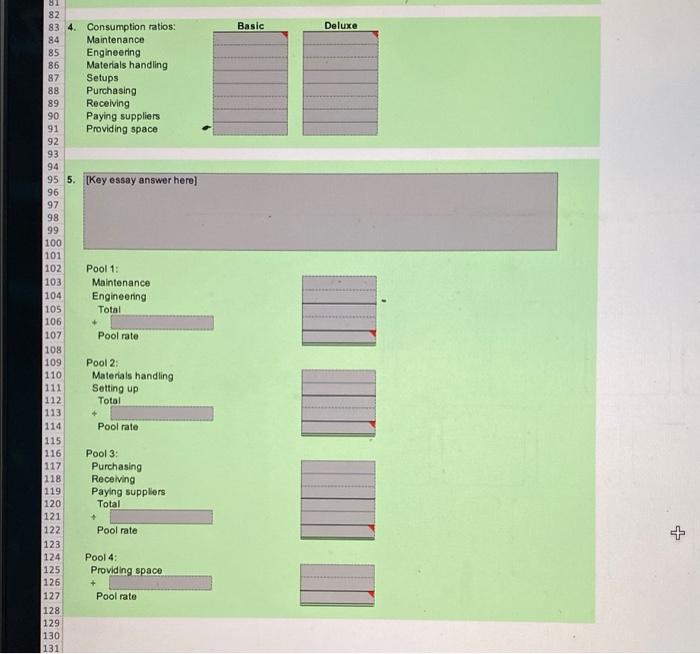

Problem 5-55 Production-Based Costing versus Activity-Based Costing, Assigning Costs to Activities, Resource Drivers Objective 1.2 Willow Company produces lawnmowers. One of its plants produces two versions of mowers: a basic model and a deluxe model. The deluxe model has a sturdier frame, a higher horsepower engine, a wider blade, and mulching capability, At the beginning of the year, the following data were prepared for this plant: EXCEL Basic Model Deluxe Model Expected quantity Selling price Prime costs Machine hours Direct labor hours Engineering support (hours) Receiving (orders processed) Materials handling (number of moves) Purchasing number of requisitions) Maintenance (hours used) Paying suppliers (invoices processed) Setting up equipment (number of setups) 40,000 $ 180 $ 80 5,000 10,000 1,500 250 1,200 100 1,000 250 16 20,000 $ 360 $ 160 5,000 10,000 4,500 500 4,800 200 3,000 500 64 dditionally, the following overhead activity costs are reported: Maintaining equipment $114,000 Engineering support 120,000 Materials handling ? Setting up equipment 96,000 Purchasing materials 60,000 Receiving goods 40,000 Paying suppliers 30,000 Providing space 20,000 Total $ "Receiving activity cost includes allocated share of forklift operators' salaries. Facility-level costs are allocated in proportion to machine hours (provides a measure of time the facility is used by each product). Receiving and materials handling use three inputs: two forklifts, gasoline to operate the forklift, and three operators. The three operators are paid a salary of $40,000 each. The operators spend 25% of their time on the receiving activity and 75% on moving goods (materials handling). Gasoline costs $3 per move. Depreciation amounts to $8,000 per forklift per year. Required: (Note: Round answers to two decimal places.) 1. Calculate the cost of the materials handling activity. Label the cost assignments as driver tracing or direct tracing. Identify the resource drivers. 2. Calculate the cost per unit for each product by using direct labor hours to assign all overhead costs. a 3. Calculate activity rates, and assign costs to each product. Calculate a unit cost for each product, and compare these costs with those calculated in Requirement 2. 4. Calculate consumption ratios for each activity. 5. Conceptual Connection Explain how the consumption ratios calculated in Requirement 4 can be used to reduce the number of rates Calculate the rates that would apply under this approach. per DLH 1 bblem 5-55 Name: 2 for the appropriate amounts or formulas in the shaded colla 3 asterisk (*) will appear in the column to the right of an incorrect amount. Essay answers will not be graded 4 und unit cont to two decimal places 6 Labor and gasoline are driver tracing Labor Time = Resource Driver Gasolino Movos = Resource Driver 9 Depreciation Time = Resource Driver 10 Total cost 11 12 Total overhead / Total direct Rate 13 labor hours 14 Plantwide rate 15 16 Unit cost Basic Deluxe 17 Prime costs 18 Overhead 19 20 21 22 Activity rates: 23 Overhead cost Activity Rate 24 Maintenance per maintenance hour 25 26 Engineering per engineering hour 27 28 Materials handling per move 29 30 Setting up per setup 31 32 Purchasing per requisition 33 34 Receiving per order processed 35 36 Paying suppliers per invoice processed 37 38 Providing space per machine hour 39 40 Unit cost: 41 Basic Deluxe 42 Expected 43 Unit cost quantity 44 Prime costs 45 46 Overhead 47 Rate Activity 48 Maintenance 49 Basic 50 Deluxe 51 Engineering + Basic Deluxe Unit cost Expected quantity Rate Activity II 40 Unit cost: 41 42 43 44 Prime costs: 45 46 Overhead: 47 48 Maintenance: 49 Basic 50 Deluxe 51 Engineering: 52 Basic 53 Deluxe 54 Materials handling: 55 Basic 56 Deluxe 57 Setting up: 58 Basic 59 Deluxe 60 Purchasing: 61 Basic 62 Deluxe 63 Receiving: 64 Basic 65 Deluxe 66 Paying suppliers: 67 Basic 68 Deluxe 69 Providing space: 70 Basic 71 Deluxe 72 Total 73 Units produced 74 Unit cost (ABC) 75 Unit cost (traditional) 76 77 [Key essay answer here] 78 79 80 81 82 83 4. Consumption ratios: 84 Maintenance 85 Engineering 86 Materials handling 87 Setups 88 Purchasing 89 Receiving 90 Paying suppliers 91 Providing space TTTTTTLINE ; Basic Deluxe 8 onun 00 00 00 Basic Deluxe 81 82 83 4. Consumption ratios: 84 Maintenance 85 Engineering 86 Materials handling 87 Setups 88 Purchasing 89 Receiving 90 Paying suppliers 91 Providing space 92 93 94 95 5. Key essay answer here) 96 97 98 99 100 101 102 Pool 1: 103 Maintenance 104 Engineering 105 Total 106 + 107 Pool rate 108 109 Pool 2: 110 Materials handling 111 Setting up 112 Total 113 + 114 Pool rate 115 116 Pool 3: 117 Purchasing 118 Receiving 119 Paying suppliers 120 Total 121 122 Pool rate 123 124 Pool 4: 125 Providing space 126 127 Pool rate 128 129 130 131 +