Currently conventional energy resources (coal, oil and gas) are used to cover about 70% of world primary energy demand. Energy conversion process with utilization of

Currently conventional energy resources (coal, oil and gas) are used to cover about 70% of world primary energy demand. Energy conversion process with utilization of these resources in thermal power plants adds huge pollutants (CO2, CO, SOx, NOx, HC, ash etc.) in the environment. Legislation bodies around the globe (environmental protection agencies like EPA-Pakistan) forces power producers to adopt policies for minimizing environmental deterioration. This problem is discussing one possible strategy on minimizing NOx emissions.

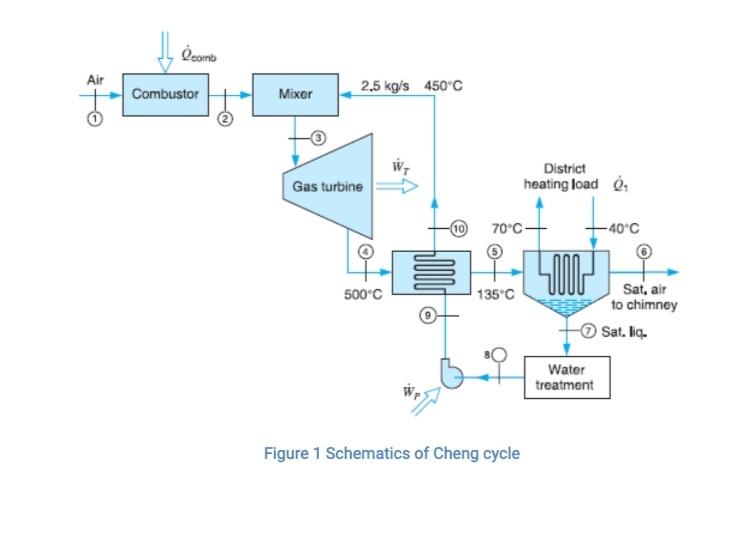

Addition of steam to combustors in gas turbines and to internal-combustion engines reduces the peak temperatures and lowers emission of NOx. Consider a modification to a gas turbine, as shown in Fig. 1 ,where the modified cycle is called the Cheng cycle. In this example, it is used for a cogenerating power plant. Assume 12 kg/s air with state 2 at 1.25 MPa, unknown temperature, is mixed with 2.5 kg/s water at 450 ◦C at constant pressure before the inlet to the turbine. The turbine exit temperature is T4 = 500◦C, and the pressure is 125 kPa. For a reasonable turbine efficiency (consult literature according to operating conditions), estimate the required air temperature at state 2. Compare the result to the case where no steam is added to the mixing chamber and only air runs through the turbine. Comment on your results from two stated cases.

Figure 1 Schematics of Cheng cycle

The Cheng cycle, shown in Fig. 1, is powered by the combustion of natural gas (essentially methane) being burned with 250–300% theoretical air. In the case with a single water-condensing heat exchanger, where T6 =40◦Cand φ6 =100%, is any makeup water needed at state 8 or is there a surplus? Does the humidity in the compressed atmospheric air at state 1 make any difference? Study the problem over a range of air–fuel ratios.Problem Description

Currently conventional energy resources (coal, oil and gas) are used to cover about 70% of world primary energy demand. Energy conversion process with utilization of these resources in thermal power plants adds huge pollutants (CO2, CO, SOx, NOx, HC, ash etc.) in the environment. Legislation bodies around the globe (environmental protection agencies like EPA-Pakistan) forces power producers to adopt policies for minimizing environmental deterioration. This problem is discussing one possible strategy on minimizing NOx emissions.

Addition of steam to combustors in gas turbines and to internal-combustion engines reduces the peak temperatures and lowers emission of NOx. Consider a modification to a gas turbine, as shown in Fig. 1 ,where the modified cycle is called the Cheng cycle. In this example, it is used for a cogenerating power plant. Assume 12 kg/s air with state 2 at 1.25 MPa, unknown temperature, is mixed with 2.5 kg/s water at 450 ◦C at constant pressure before the inlet to the turbine. The turbine exit temperature is T4 = 500◦C, and the pressure is 125 kPa. For a reasonable turbine efficiency (consult literature according to operating conditions), estimate the required air temperature at state 2. Compare the result to the case where no steam is added to the mixing chamber and only air runs through the turbine. Comment on your results from two stated cases. The Cheng cycle, shown in Fig. 1, is powered by the combustion of natural gas (essentially methane) being burned with 250–300% theoretical air. In the case with a single water-condensing heat exchanger, where T6 =40◦Cand φ6 =100%, is any makeup water needed at state 8 or is there a surplus? Does the humidity in the compressed atmospheric air at state 1 make any difference? Study the problem over a range of air–fuel ratios.

The Cheng cycle, shown in Fig. 1, is powered by the combustion of natural gas (essentially methane) being burned with 250–300% theoretical air. In the case with a single water-condensing heat exchanger, where T6 =40◦Cand φ6 =100%, is any makeup water needed at state 8 or is there a surplus? Does the humidity in the compressed atmospheric air at state 1 make any difference? Study the problem over a range of air–fuel ratios.

Assessment Rubrics

Estimation of mixture properties [4]

Selection of turbine efficiency with reasonable arguments [2]

Calculation of turbine inlet temperature with consideration of mixture properties [3]

Consideration of thermal losses in the mixture [2]

Energy balance across mixer [2]

Mass and energy balance across condensing heat exchanger [4]

Effect of variable humidity and air-fuel ratio [3]

Air 2,5 kg/s 450C Combustor Mixer District Gas turbine heating load 0, 10 70C- -40C Sat, air to chimney Sat. liq. 500C 135C Water treatment Figure 1 Schematics of Cheng cycle

Step by Step Solution

3.43 Rating (159 Votes )

There are 3 Steps involved in it

Step: 1

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started